EN

Six monthly operations

Have the machine checked by personnel trained and authorised by the manufacturer.

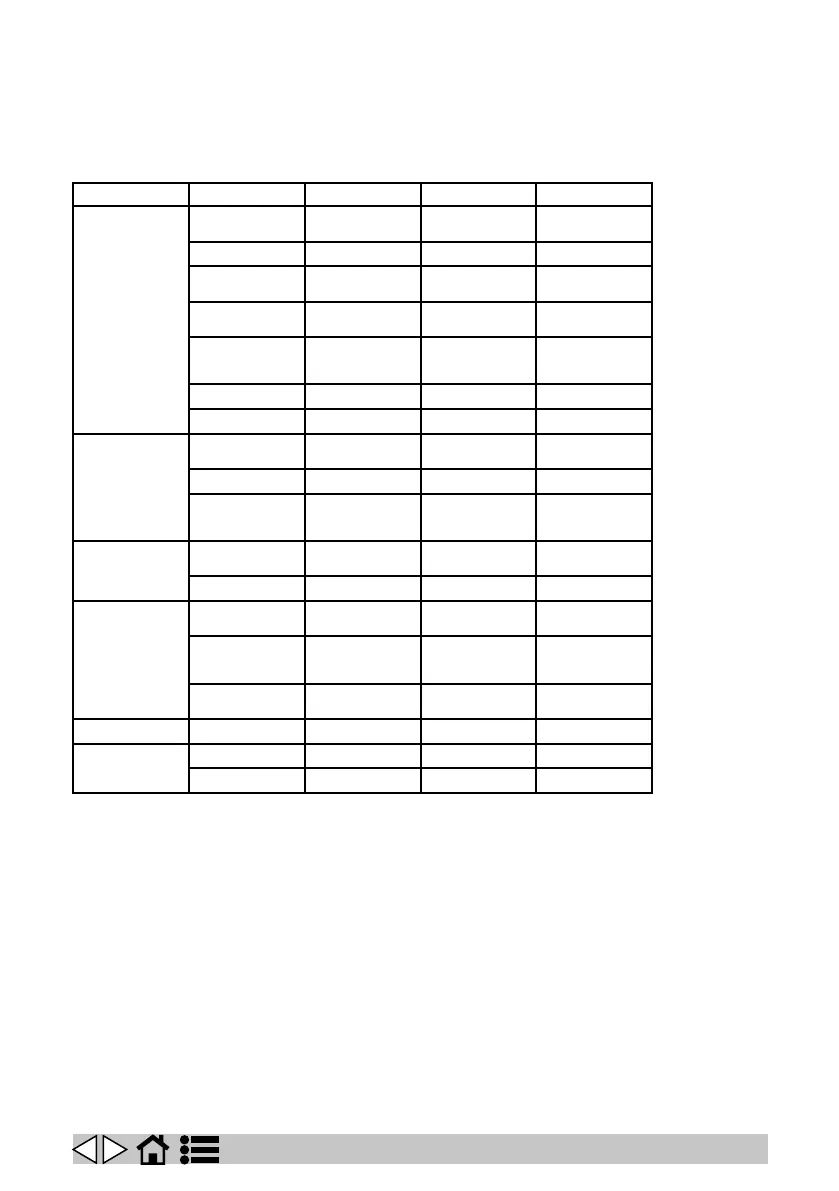

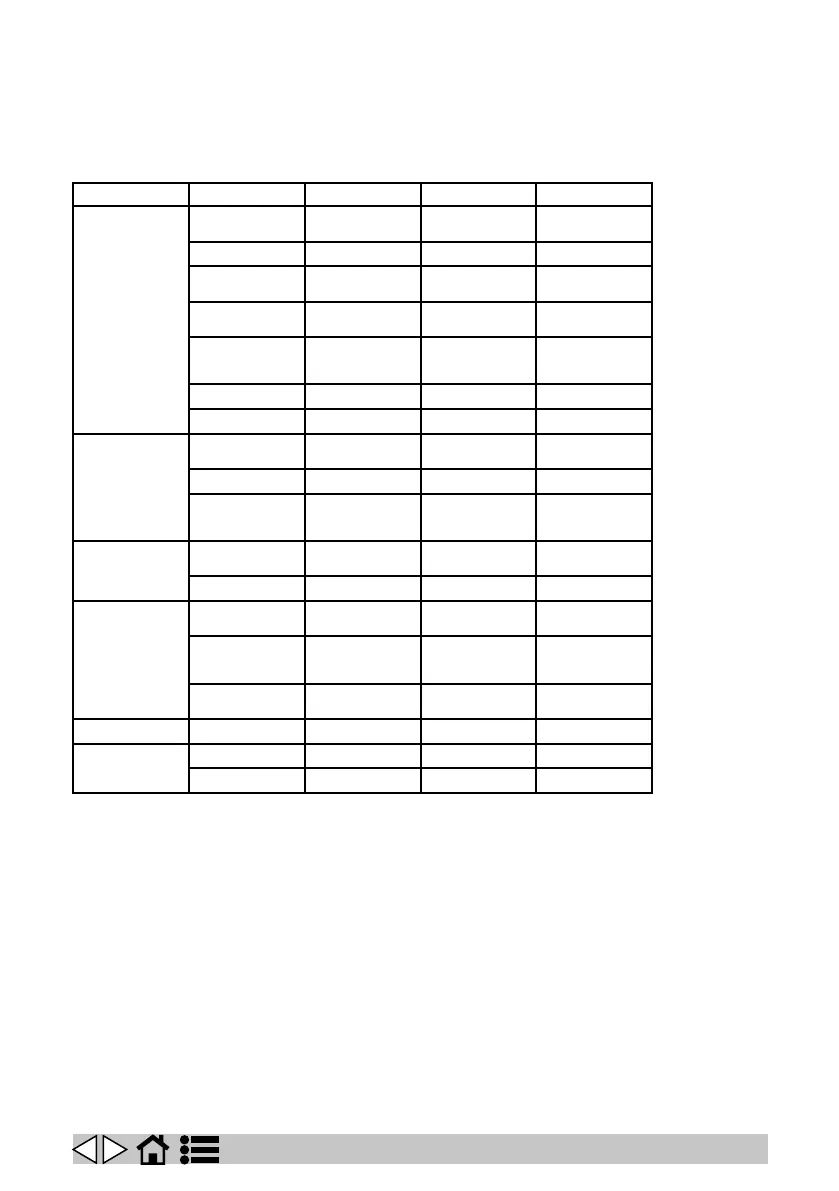

Maintenance

The following table species the role responsible for each procedure.The following table species the role responsible for each procedure.

O = OperatorO = Operator

A = personnel trained and authorised by the manufacturer.

Interval Responsible Description Procedure Lubricant/Liquid

Daily

O

Pad Check, rotate or re-

place

O

Brush/es Check and clean

O

Squeegee Clean and check for

wear or damage

O

Spray shield Check for wear or

damage

O

Dirty water tank Empty, rinse, clean

oat guard and waste

basket

O

Solution tank Empty, rinse

O

Batteries Recharge if needed

Weekly

O

Batteries Check the electrolyte

level

DW

O

Battery compartment Check for leakage

O

Squeegee assem-

bly siphon (two-disc

model)

Check. Clean

50 hours

O

Dirty water tank lid

gasket

Check for wear

O

Detergent tank lter Remove and clean

200 hours

O

Batteries, terminals

and cables

Check and clean

A

Steering chain Lubricate, adjust ten-

sion and check for

wear or damage

GO

A

Steering cable Check tension. Check

for wear or damage

750 hours

A

Suction motor Replace the brushes

1250 hours

A

Drive motor Replace the brushes

A

Brush motors Replace the brushes

LUBRICANT/LIQUIDLUBRICANT/LIQUID

DW Distilled waterDW Distilled water

ACD Approved commercial detergentACD Approved commercial detergent

GO SAE W90 gear oilGO SAE W90 gear oil

31

Loading...

Loading...