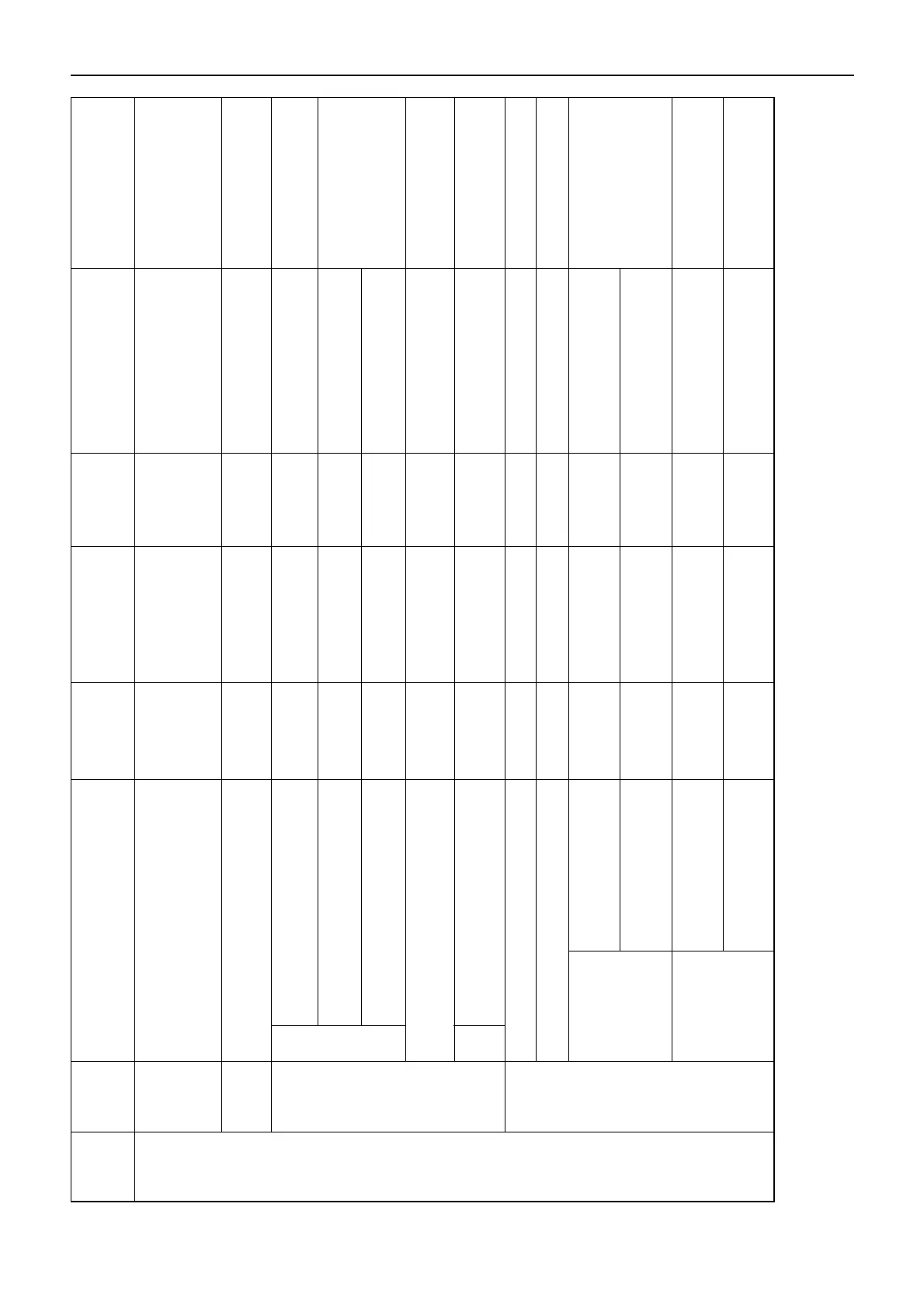

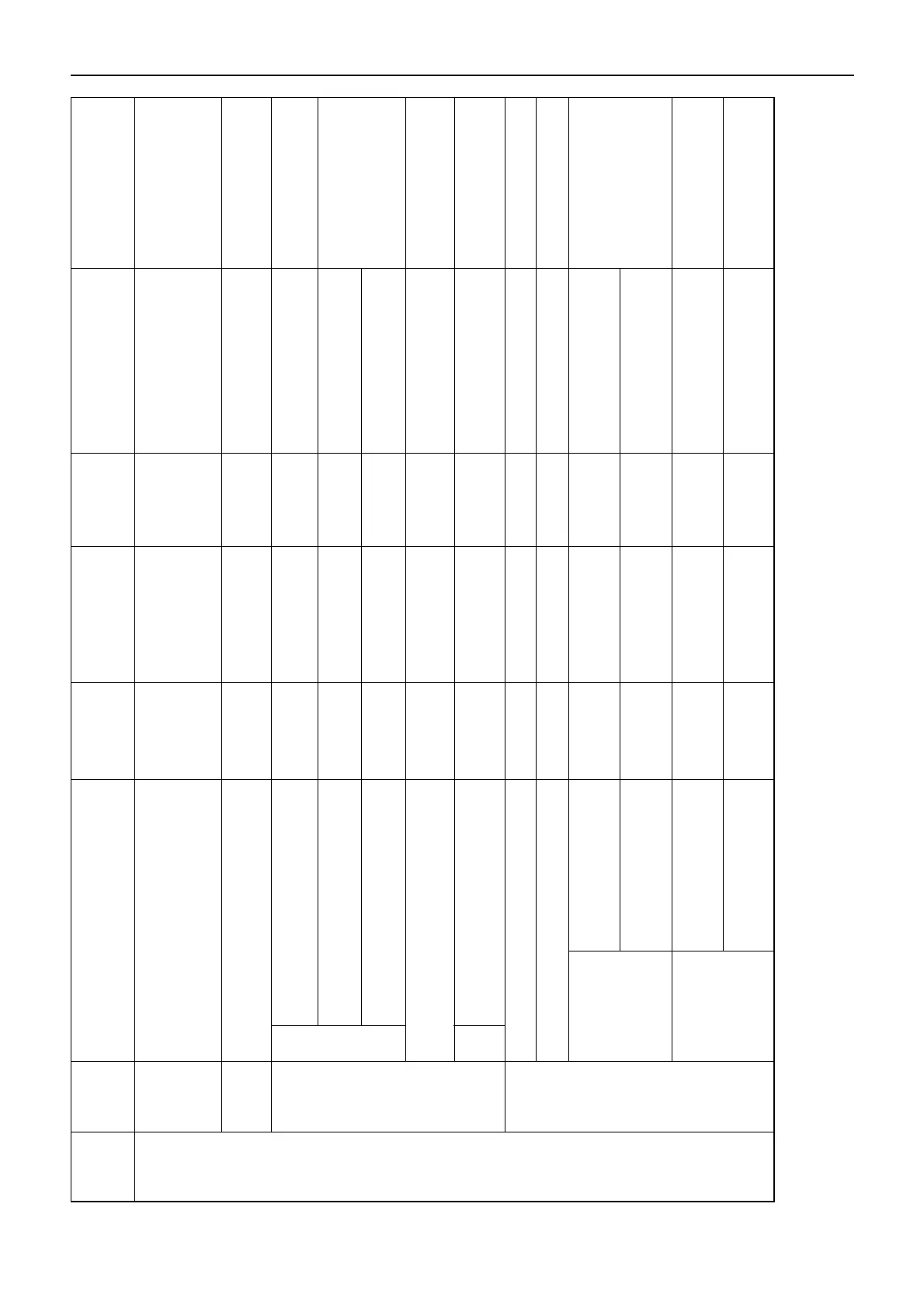

REPAIR STANDARDS

216

Major Name Nominal

Assembly

Category

of Part

Inspection Item

Dimension

Standard Limit Repair Procedure Comments

Value

If warning indicator lights

when engine is operating

Warning lamp indication

a

t

normal speeds, check

and repair electrical system.

Check for looseness, cuts or damaged

Repair

insulation to wiring.

Shaft runout

0.1 (0.0039)

Replace rotor

or ress

Bearing chatter Replace bearings

Rotate by handand check

for smooth rotation:

no abnormal sound or

Thrust side chatter 0.3 (0.012) Repair

resistance should be felt.

Slip ring dia waler

31.6 30.6

Replace

(1.24) (1.20)

Length

14.5 7.5

(0.57) (0.3)

Loose mount Repair

Brush length 15.0 (0.59) 9.0 (0.35) Replace

Jeries coil

—

Magnetic resistance (Ω) If coil resistance value

switch is severely abnormal,

(at 20°C [68°F])

Shut coil

0.27

replace switch.

resistance (Ω)

O.D.

Dia. 30.0 Dia. 29.0

Replace armature

Commutator

(1.18) (1.14)

Undercut depth

0.5 – 0.8 0.2

Repair

(0.02 – 0.03) (0.008)

Electrical

Charge/

Discharge

indication

Wiring

Alternator 12V, 35A

(Hitachi 1-81200-756-0)

Rotor

Brush

Starter 12V, 2.2 kW

(Hitachi 8-97084-879-0)

Loading...

Loading...