10

RESCUE GUIDE ‒ Technical information

TECHNICAL INFORMATION

CNG / CNG-PETROL VEHICLES (NATURAL POWER)

– Printed 692.68.340 – 1st Ed. 04/2015

Manual closure for maintenance and shut-off

Solenoid valve(3) controlled by ignition key.

The solenoid valve is one-way and does not shut off the flow into the cylinder; thus the cylinders must be charged when the solen-

oid valves are not powered.

Safety functions:

● Flow limiter (2) that intervenes in the event of a sudden change in pressure, effectively limiting the outward flow of gas

from the cylinders; for example if a pipe breaks. After the downstream leak has been eliminated, and the pressure equilibrium

has been re-established, the outflow limiter valve in its closed position still allows a small flow of gas to enable resetting the

device.

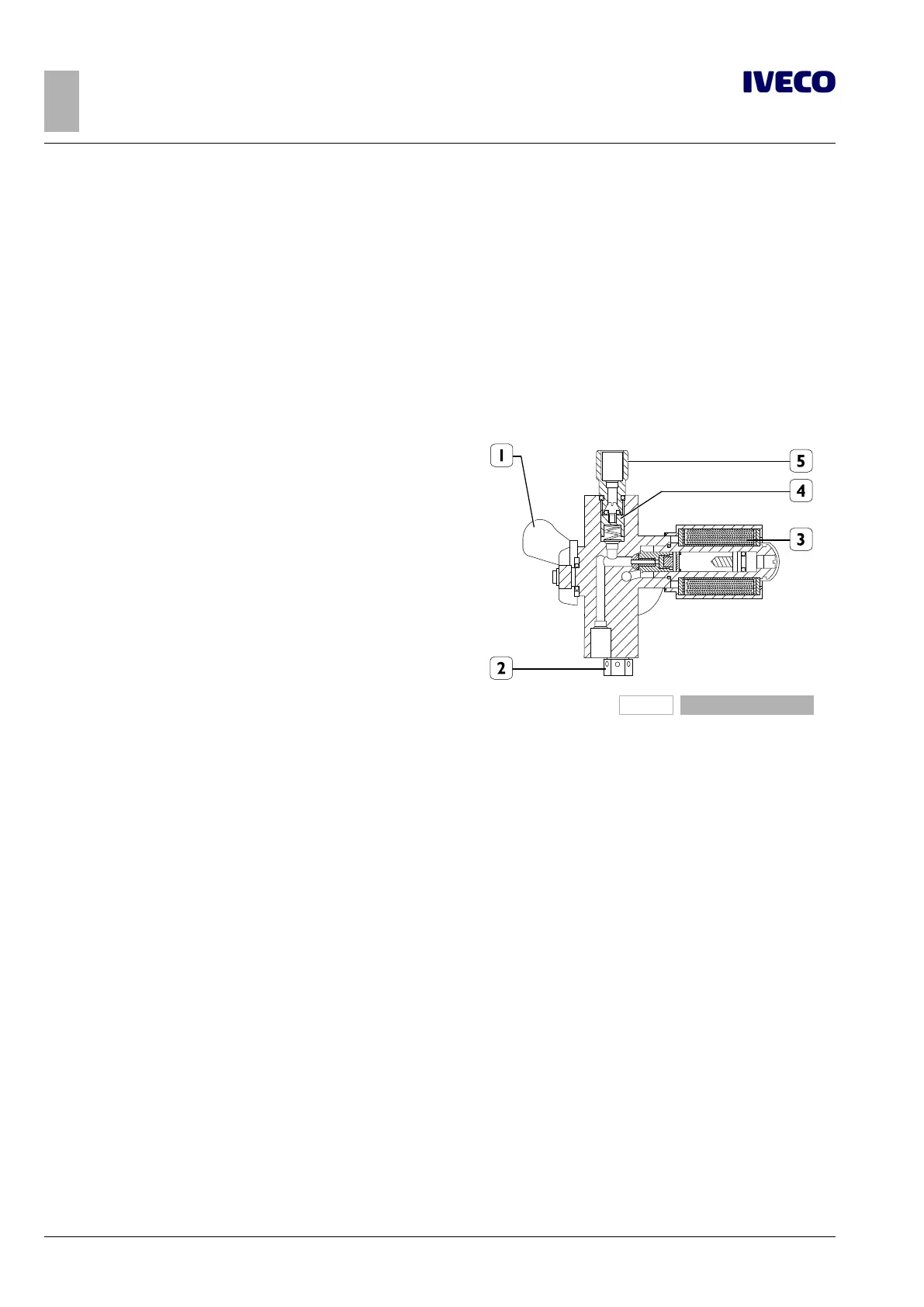

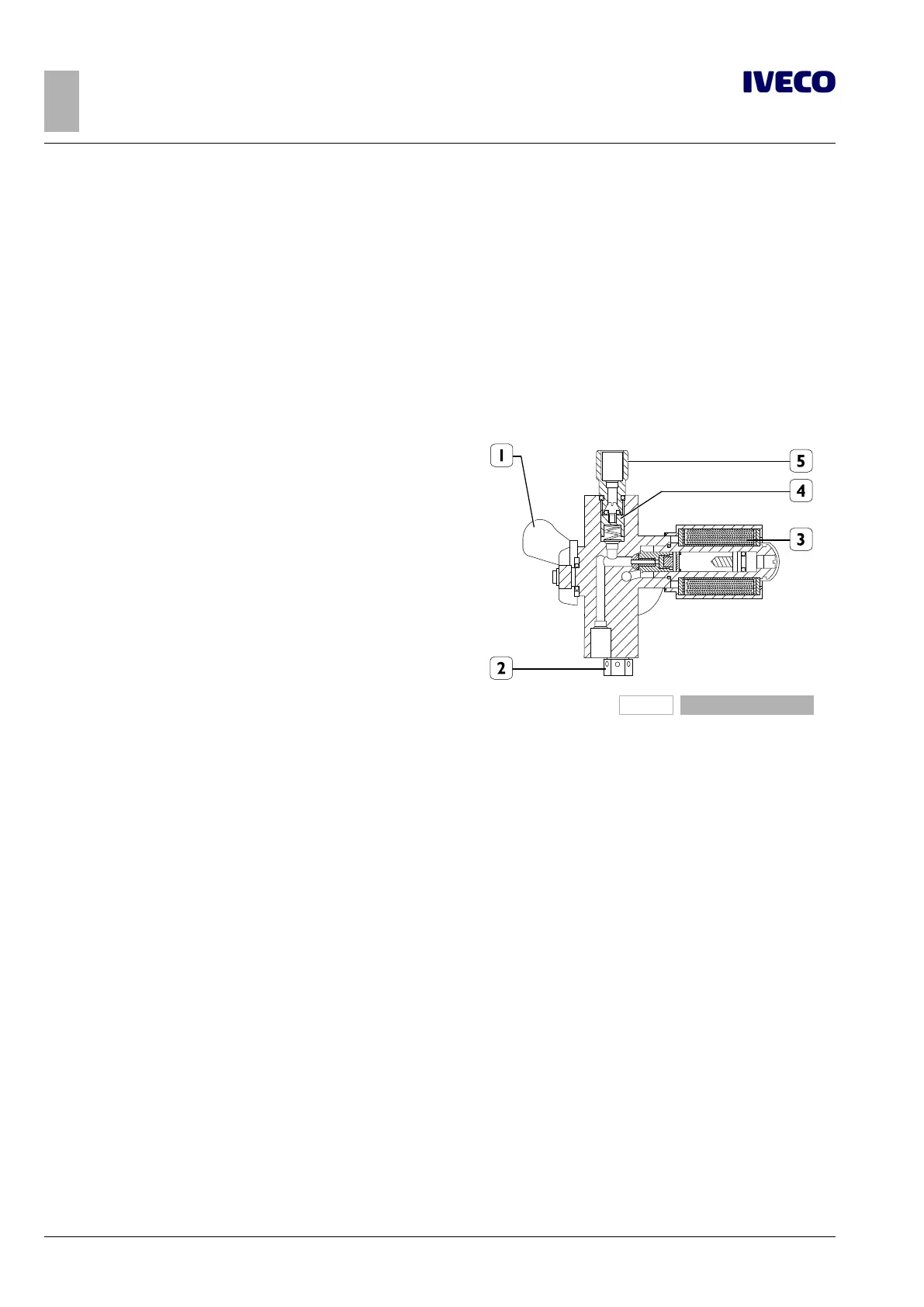

VBE 498 solenoid valve with check valve

117673

Figure 11

1 Tap

2 Discharge device with

fusible plug

3 Solenoid valve

4 Check valve

5 Gas inlet union

● fusible plug locked in the discharge device (2) that melts at 110±10°C.

The safety circuit, composed of the fusible plug, allows the gas to be discharged safely in case of fire on the vehicle, preventing cylin-

der explosions due to overpressure.

This circuit communicates directly with the exterior independently of: outflow limiter valve, manual valve and solenoid valve.

Upstream of the interceptor solenoid valve there is a manual tap valve which performs the same function as the previous solenoid

valve, but is operated manually; its presence is important in case of any maintenance of the system, when it becomes necessary to

close the cylinders.

The solenoid valve fitted on the first cylinder is connected to the filling valve and is equipped with a check valve.

The function of this valve is to prevent the flow of CNG from the cylinder to the filling valve and is moreover another safety ele-

ment as it is in addition to the valve in the filling valve.

The valve opens due to the pressure of the gas during filling.

● Flow limiter: if a pipe bursts or the valve assembly breaks (for example due to an accident), CNG escapes (gas leak) and

the flow limiter trips to limit the flow of CNG to approximately 0.5% of the setting for normal engine operation, eliminating

the danger deriving from the presence of a considerable flow rate of CNG. The flow limiter is positioned in the threaded

shank of the valve assembly so as to remain inside the cylinder, ensuring operation even in the event of the solenoid valve

body breaking as a result of an accident.

Loading...

Loading...