RESCUE GUIDE ‒ Technical information

TECHNICAL INFORMATION

CNG / CNG-PETROL VEHICLES (NATURAL POWER)

11

– Printed 692.68.340 – 1st Ed. 04/2015

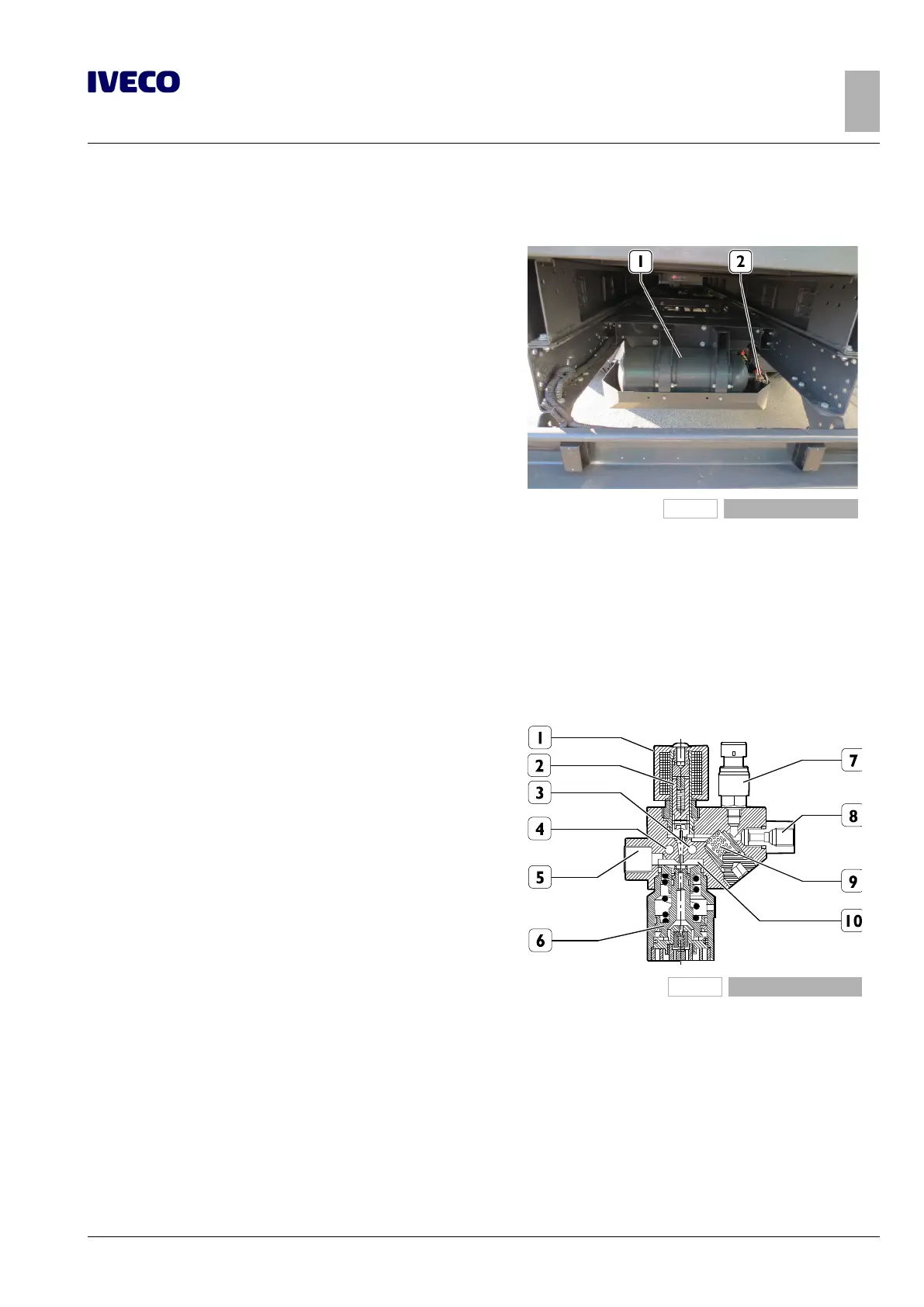

Cylinders description

Solenoid valve on cylinder

226155

Figure 12

1 Cylinder 2 Solenoid valve

The CNG, compressed at a pressure of 200 bar, is stored in some cylinders, positioned in the chassis frame and protected by spe-

cial sheet metal guards.

The cylinders, connected together in series, are filled via a filling valve equipped with a check valve.

A second check valve is included in the solenoid valve fitted on the first cylinder connected to the filling union.

The function of the check valves is to prevent the gas escaping outwards and the dispenser being removed from the filling valve

after refilling or a pipe bursting.

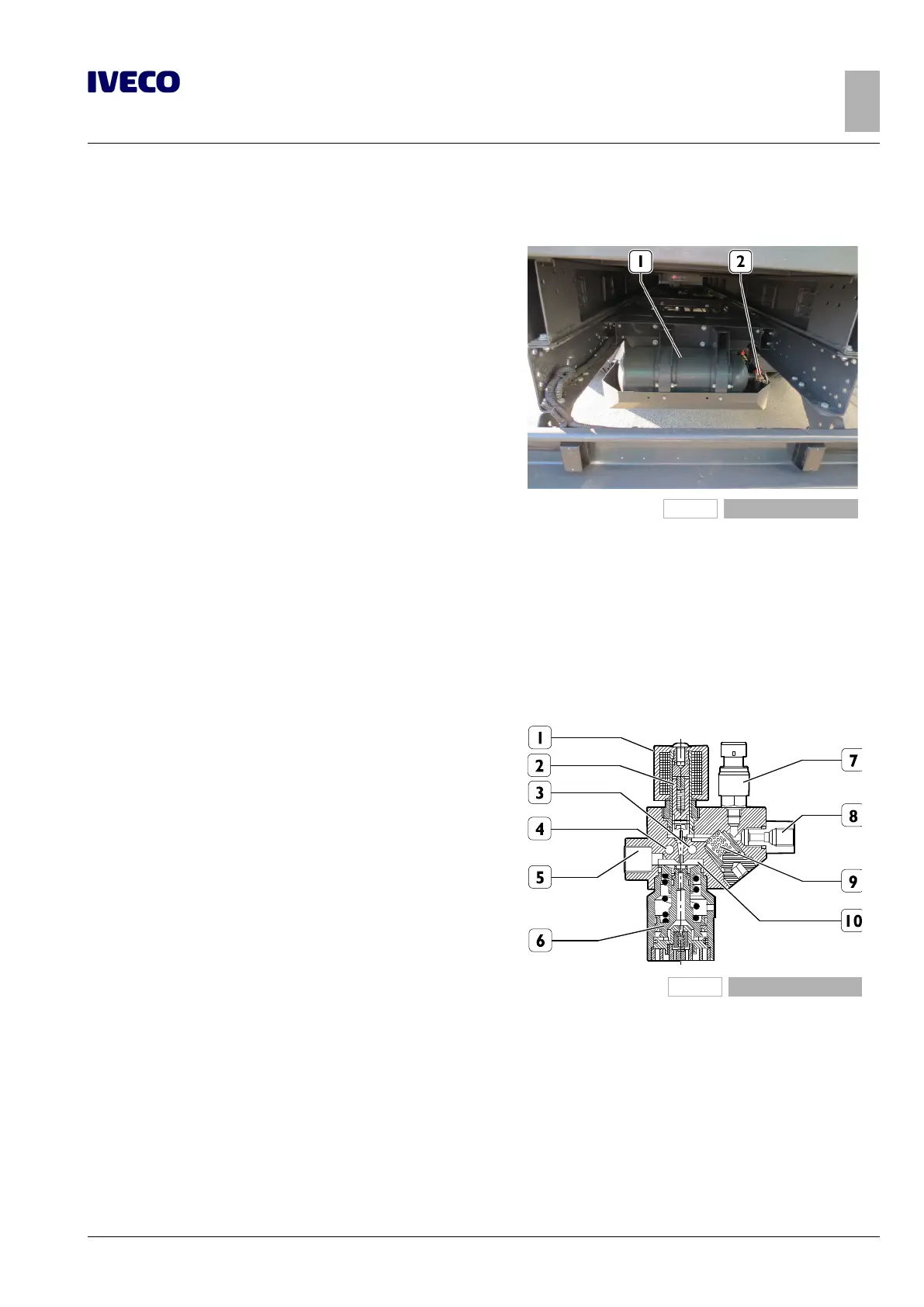

Pressure reducer description

138645

Figure 13

1 Solenoid valve

2 Valve mobile equip-

ment

3 Cooling water duct

4 Cooling water duct

5 Low pressure CNG

outlet

6 Reducer valve mobile

equipment

7 CNG pressure sensor

8 High pressure CNG

inlet

9 Filter

10 Discharge chamber

The pressure reducer decreases the CNG pressure from the value

in the cylinders to the electric injector supply value (6 ± 1 bar), in all

engine operating conditions.

The pressure reduction takes place in a single stage in which the

pressure is reduced from 200 to 6 bar

Since the CNG drops sharply in temperature because it expands due

to the jump in pressure, the engine cooling circuit has a branch that

allows the engine coolant to heat the pressure reducer assembly so

as to avoid any trouble due to the change in temperature, such as the

formation of condensation or even ice that could block the pressure

reducer.

It is equipped with a CNG shut-off solenoid valve and a CNG pres-

sure sensor.

Loading...

Loading...