MARCH 2004COOLING

8.83

MARINE ENGINES INSTALLATION

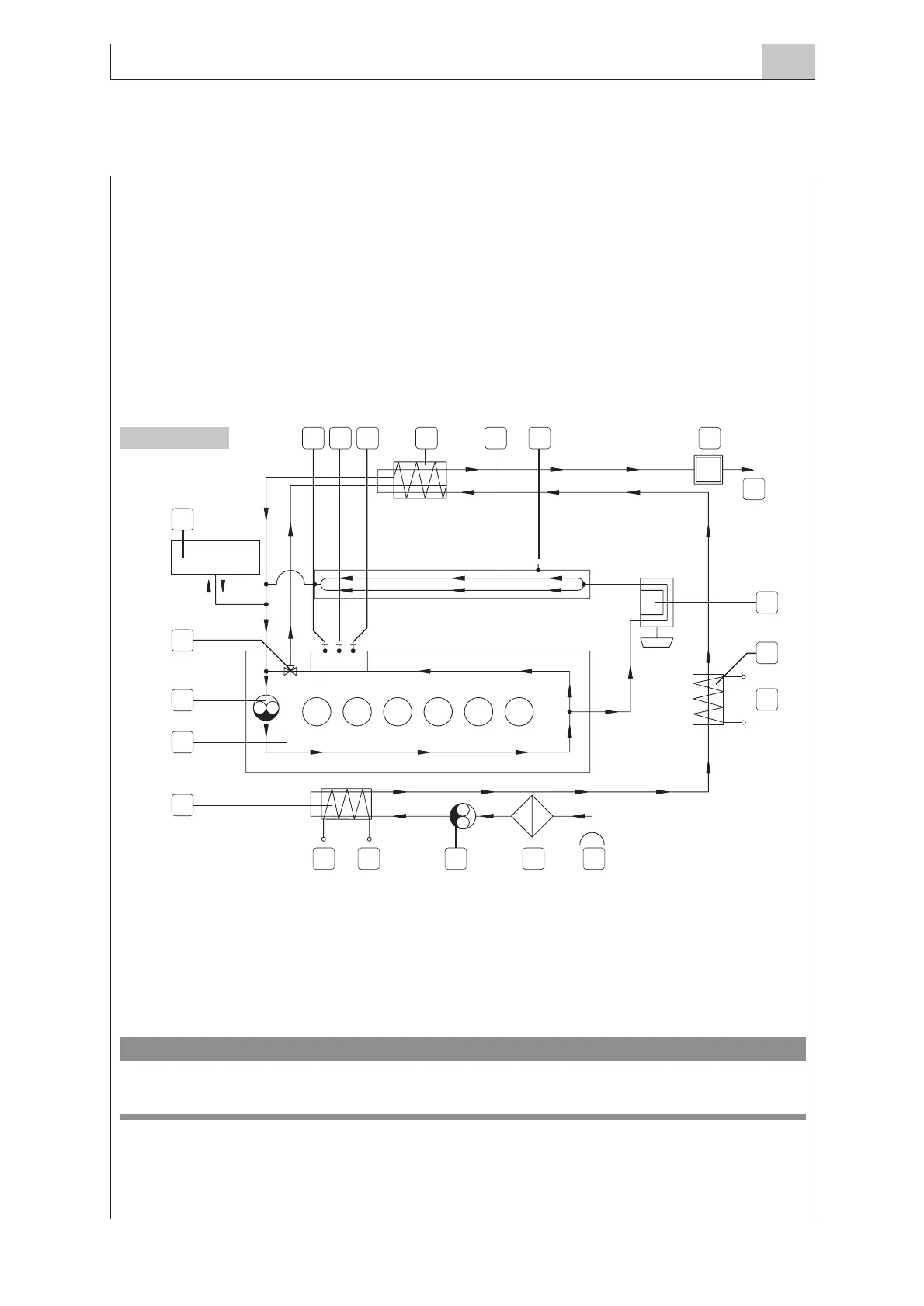

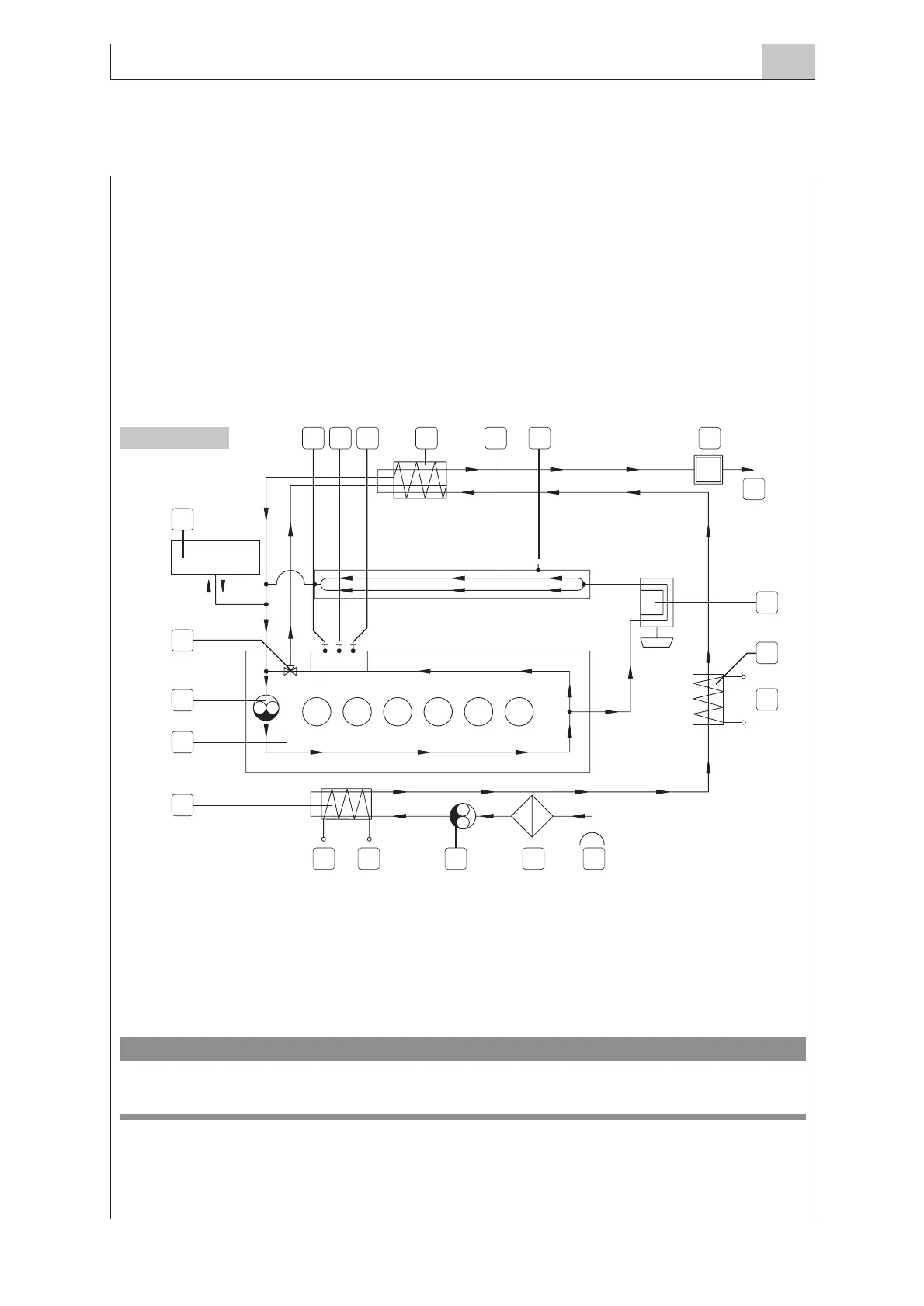

The aim of the cooling system is to keep the engine at a constant temperature to ensure proper func-

tioning and guarantee the expected nominal performance.

Marine engines are generally provided with a cooling system made up of two circuits:

■ A closed and pressurised primary circuit through which coolant circulates (water 50% and Paraflu

11 or its equivalent, complying with SAE J 1034).

■ An open secondary circuit through which water is taken into and out of the hull.

The heat removed by the coolant in the primary circuit is then passed to the secondary circuit water

in the heat exchanger.

The cooling systems also include lubricant oil; intercooler and transmission oil heat exchangers, if needed.

1. Water temperature sensor. - 2. Water temperature sensor (EDC). - 3. Water/water heat exchanger.

- 4. Refrigerated exhaust manifold. - 5. Water drain plug. - 6. Seawater/waste gas mixer. -

7.Turbo-compressor. - 8. Oil inverter heat exchanger. - 9. Seawater filter. - 10. Seawater pump. -

11. Air/water heat exchanger. - 12. Engine base. - 13. Primary circuit water pump. - 14. Primary circuit

thermostatic valve. - 15. Pressurised expansion tank. - 16. Water high temperature transmitter.

A. Sea discharge - B.To inverter - C. Seawater suction -

D. /E. Air passage from turbocharger to engine.

CAUTION

To avoid overheating and damage to engine elements, the engine must not run without coolant or

water in the secondary circuit.

In some cases, the cooling system is only one single circuit.The heat exchange is done through the keel

or the hull wall, the “keel-cooling” system.

8.1 INSTALLATION

Loading...

Loading...