AEX12GRN

3 – 8

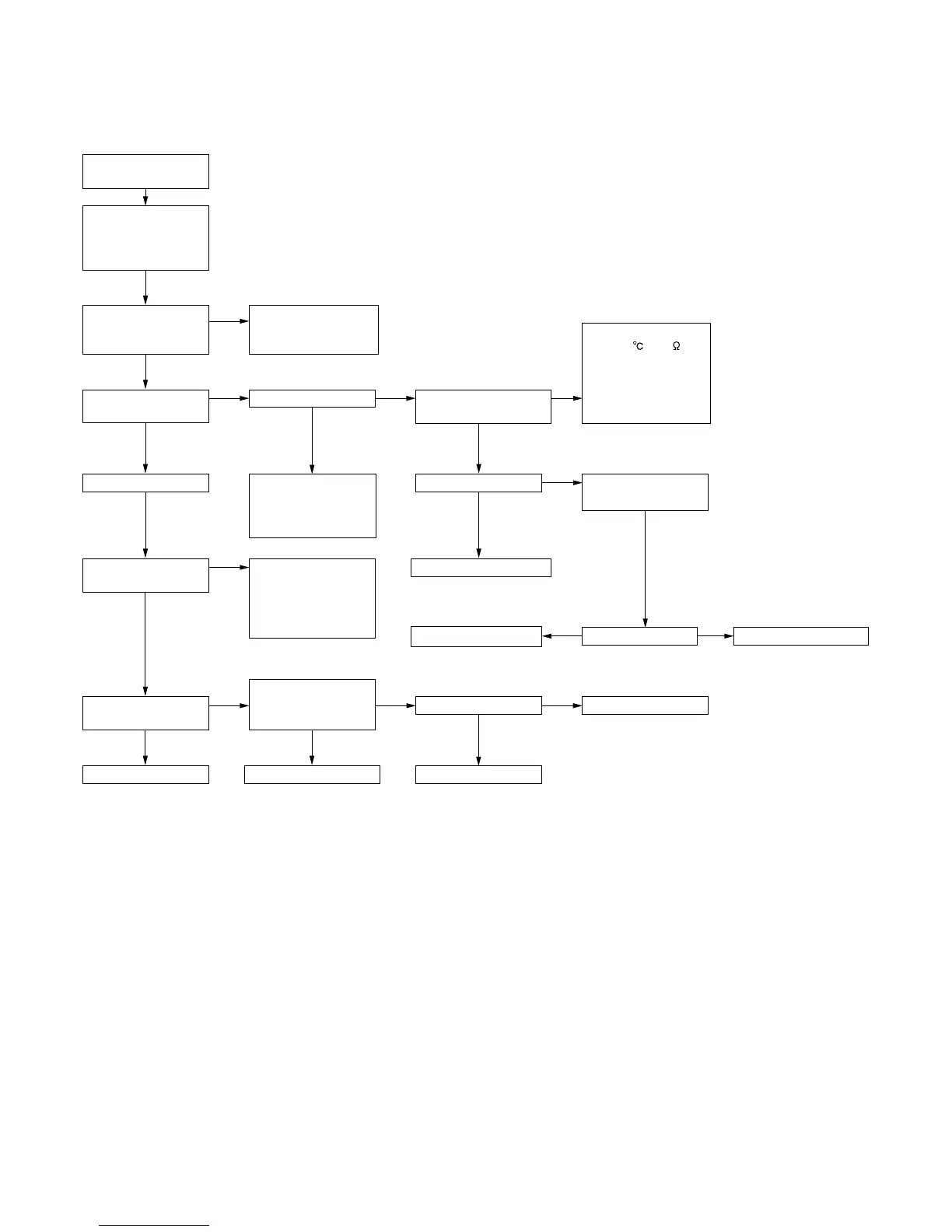

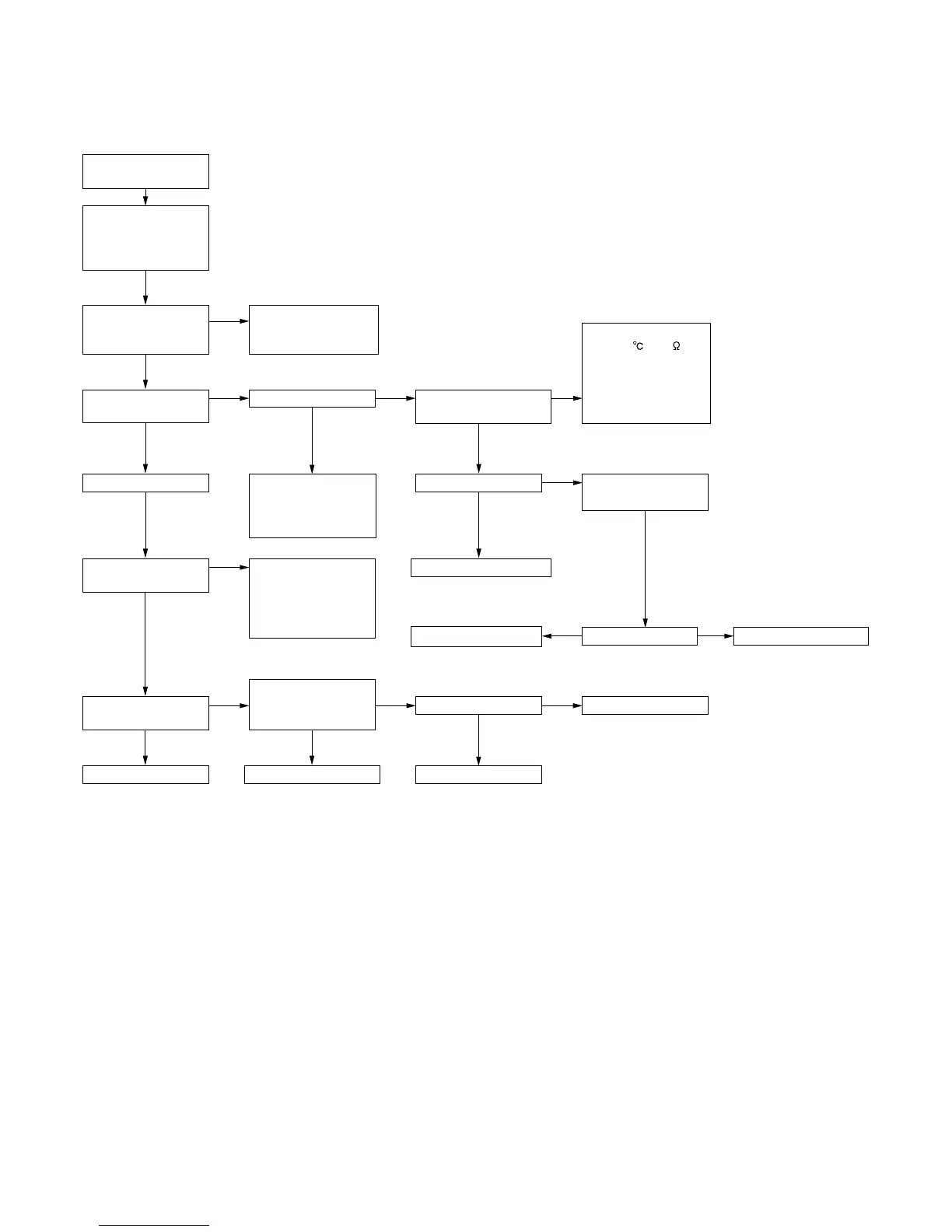

[6] MALFUNCTION (PARTS) CHECK METHOD

1. Procedure for determining defective outdoor unit IPM/compressor

The following flow chart shows a procedure for locating the cause of a malfunction when the compressor does not start up and a DC overcurrent indi-

cation error occurs.

YES

Immediately

after startup

YES

YES

NO

NO

NO

YES

NO

Connect power cord

to AC outlet.

Normal

NO

Replace outdoor unit PWB.

Using remote control,

operate air conditioner

so that compressor

starts.

Is there 230 VAC

between (1) and (N)

on outdoor unit PCB?

Is LED1 on outdoor

unit flashing?

Compressor starts up.

Does LED1 indicate

DC overcurrent error?

Does LED1 indicate

rotation error?

Outdoor unit PWB.

15/5 V display section.

Voltage OK.

Replace compressor.

Check inter-unit wiring.

Check indoor unit PWB.

Does LED1 remain lit?

Serial signal error.

Check inter-unit wiring.

Check indoor and

outdoor unit PWBs.

Replace outdoor unit

PWB.

Check compressor.

2/3-way valve closed.

Refrigerant shortage.

Replace outdoor unit

Is there 320 VDC between

pins IPM (31) and (35)?

+13 V, +15 V on PWB.

+13 V on PWB.

Replace outdoor unit PWB.

Replace expansion valve.

End.

Check posistor (PTC1)

(about 40 at 25 ).

Check IPM.

Check fan motor.

Check outdoor unit PCB.

Check wiring.

Check PAM IGBT (Q5).

Disconnect expansion

valve connector.

Replace outdoor unit PWB.

After about

20 seconds

YES

NO

NO

YES

NO

NO

YES

YES YES

No

(unlit)

OK

Loading...

Loading...