15

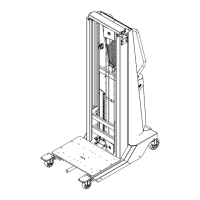

OPERATING MANUAL – DataLift 250

DAILY OPERATIONAL INSPECTION AND MAINTENANCE

Check the DataLift daily before use, paying particular attention to the wheels and cable. Foreign objects

such as cloths, etc. can block the wheels, table, mast or cable. After nishing working with the DataLift and

before checking, unload the table and lower it to the lowest position.

• Do a visual inspection for damage to wires, scratches, deformation, cracks or loose screws.

• Check the cable for damage and weakness, also block wheels for free movement.

• Check the condition of the unit when driving straight ahead.

• Check that the wheel moves smoothly.

• Press the emergency stop button to check the emergency stop function.

• Check brake function.

• Press the buttons to check the lifting and lowering function.

CHECKLIST FOR MAINTENANCE / INSPECTION

In addition to the daily inspection is the yearly inspection. National regulations may require additional

inspections.

Remove the back cover.

Inspect the cable for:

• Wear or corrosion

• Broken wires

• Uneven strands, crushed parts, knots, uneven diameter

In case of damage do not use the unit until the cable was changed by a technician!

Inspect block wheels:

• Check if there are cracks, wear, bent

• Check xing rings

• Check bearings for smooth run/noise

Inspect winch:

• Capability of holding the Max. load

• Wear on drum

• Fixing of the cable on the drum. Are the screws tight.

• Min. 5 layers of cable on the drum

Loading...

Loading...