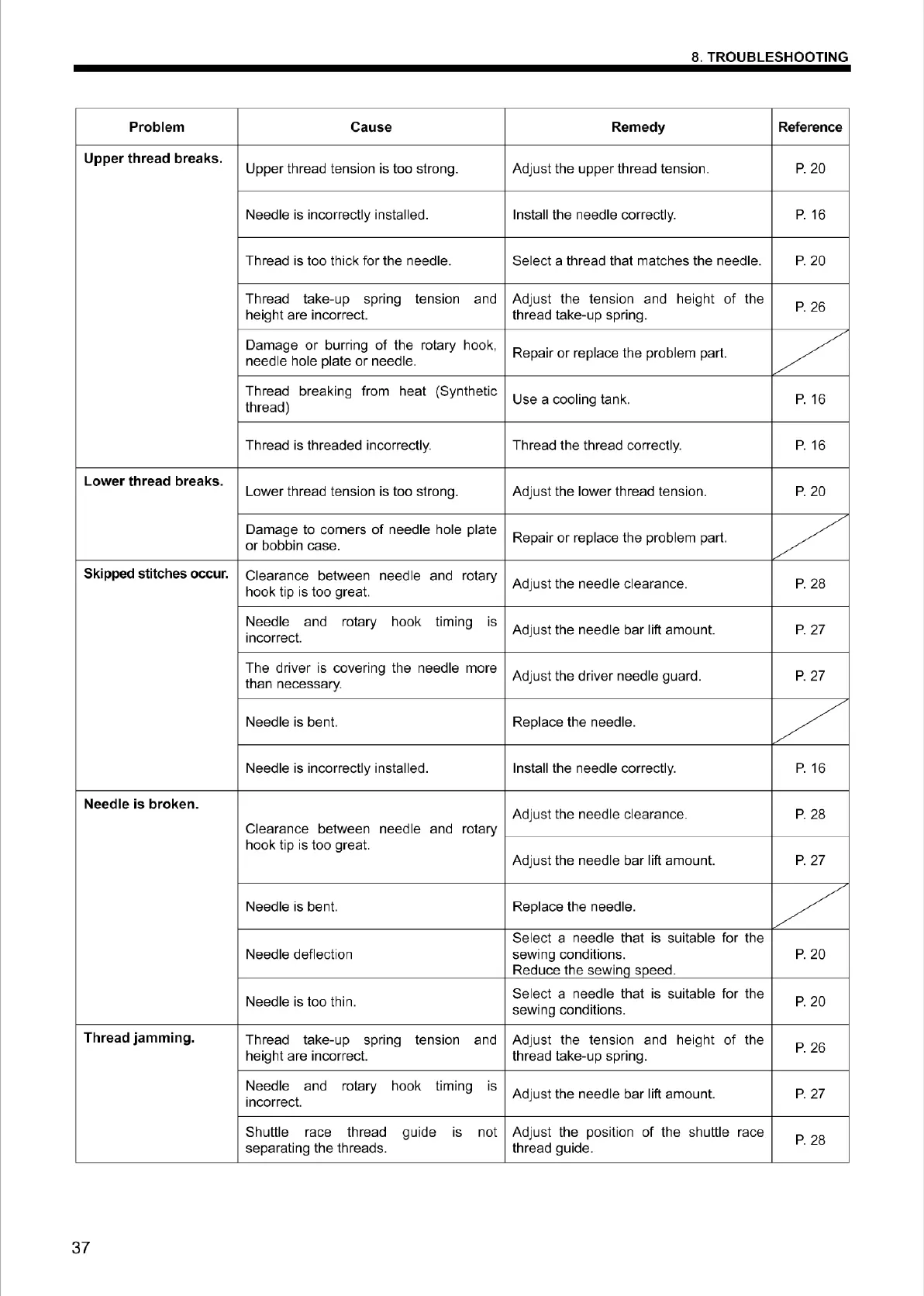

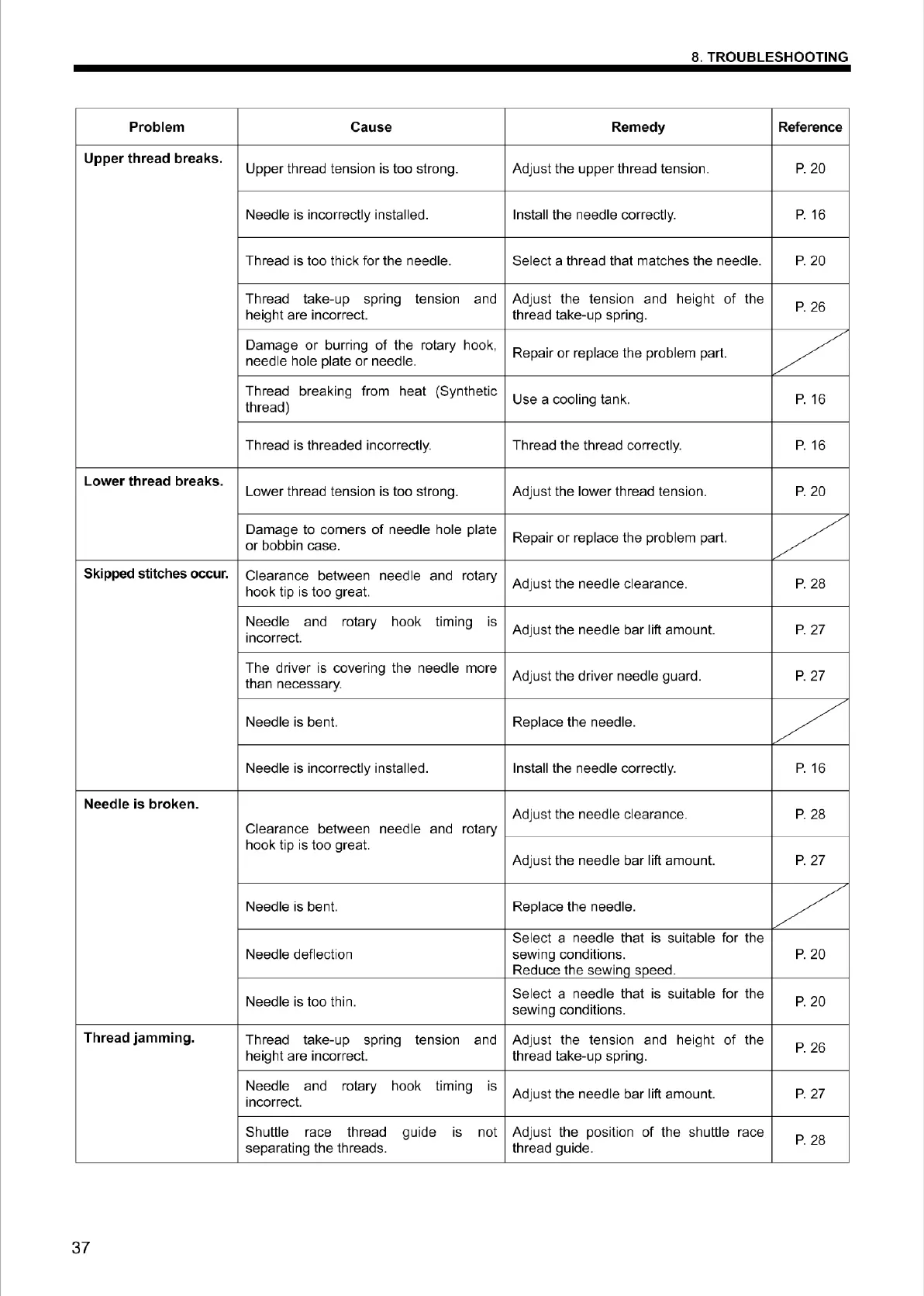

8. TROUBLESHOOTING

Problem Cause Remedy Reference

Upper thread breaks.

Upper thread tension is too strong. Adjust the upper thread tension. P.20

Needle is incorrectly installed. Install the needle correctly.

P.

16

Thread is too thick for the needle. Select a thread that matches the needle.

P.

20

Thread take-up spring tension and Adjust the tension and height

of

the

P.

26

height are incorrect. thread take-up spring.

Damage

or

burring

of

the rotary hook,

Repair

or

replace the problem part.

/

needle hole plate

or

needle.

Thread breaking from heat (Synthetic

Use a cooling tank.

P.

16

thread)

Thread is threaded incorrectly. Thread the t

hr

ead correctly.

P.

16

Lower thread breaks.

Lower thread tension is too strong. Adjust the lower thread tension.

P.

20

Damage to corners

of

needle hole plate

Repair

or

replace the problem part.

/

or bobbin case.

Skipped stitches occur.

Clearance between needle and rotary

Adjust the needle clearance.

P.

28

hook tip is too great.

Needle and rotary hook timing is

Adjust the needle bar lift amount.

P.

27

incorrect.

The driver is covering the needle more

Adjust the driver needle guar

d.

P.

27

than necessary.

Needle is bent. Replace the needle.

/

Needle is incorrectly installed. Install the needle correctly.

P.

16

Needle is broken.

Adjust the needle clearance.

P.

28

Clearance between needle and rotary

hook tip is too great.

Adjust the needle bar lift amount.

P.

27

Needle is bent. Replace the needle.

/

Select a needle that is suitable for the

Needle deflection sewing conditions.

P.

20

Reduce the sew

in

q speed.

Needle is too thin.

Select a needle that is suitable for the

P.

20

sewing conditions.

Thread jamming.

Thread

take-up spring

tension and Adjust the tension and height

of

the

P.

26

height are incorrect. thread take-up spring.

Needle and rotary hook timing is

Adjust the needle bar lift amount.

P.

27

incorrect.

Shuttle race thread guide is not Adjust the position

of

the shuttle race

P.

28

separating the threads. thread guide.

37

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...