3. INSTALLATION

3. INSTALLATION

AcAUTION

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer

or

a qualified electrician

for any electrical work that may need to be done.

The sewing machine head weighs approximately

88kg. The installation should be carried out by two or

more people.

Do not connect the power cord until installation is

complete.

If

the foot switch is depressed by mistake, the sewing

machine might start operating and injury could resul

t.

Hold the machine head with both hands when tilting it

back or returning it to its original position.

Furthermore,

do

not apply excessive force when tilting

back the machine head. The sewing machine may

become unbalanced and fall down, and serious injury

or

damage to the sewing machine may result.

0

All cords should be secured

at

least 25 mm away from

any moving parts. Furthermore, do not excessively

bend the cords or secure them too firmly staples,

otherwise there is the danger that fire or electric

shocks could occur.

Be sure to connect the ground. If the ground

connection is not secure, you

run

a high risk of

receiving a serious electric shock, and problems wi

th

correct operation may also occur.

Install the safety covers to the machine head and

motor.

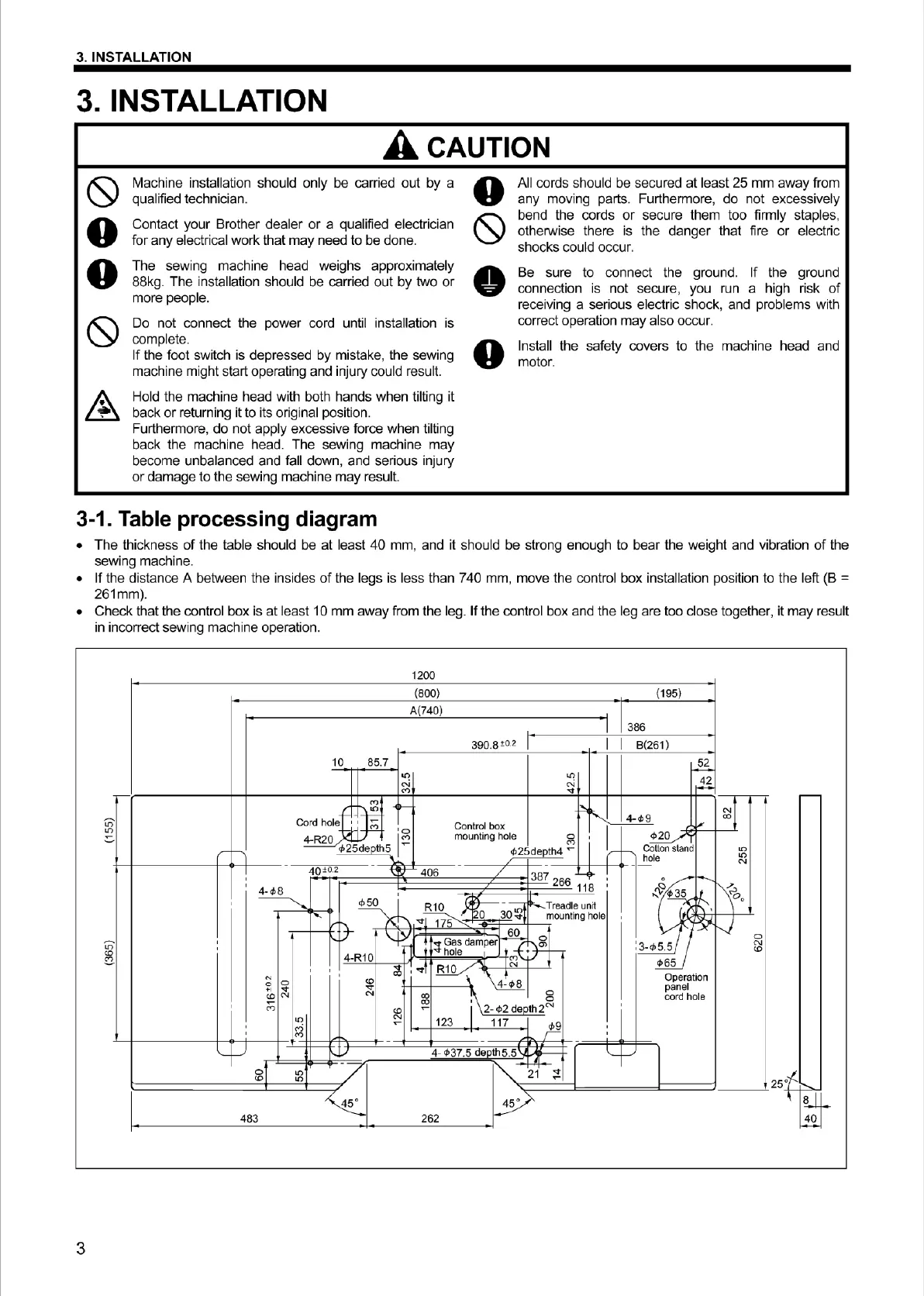

3-1. Table processing diagram

• The thickness

of

the table should be at least

40

mm, and it should be strong enough to bear the weight and vibration

of

the

sewing machine.

• If the distance A between the insides

of

the legs is less than 740 mm, move the

co

nt

rol

box installation positi

on

to the left (B =

261mm).

• Check that the control box is

at

least 10 mm away from the leg.

If

the control box and the leg are too close together, it may result

in

incorrect sewing machine operation.

1200

(800)

(

195)

A(74O)

3

86

390

.8 •

02

I I

8(261)

10

85.7

~

"'

"!

42

N N

"'

st

-

"'

.,_

~~

~1

/"

,.,,

Cord hole

' ' ~

4-

¢9

1,,-

"'

'o

Control

box

~

4-R20

I"'

mounting hole 0

i

¢20

"'

~

~

<t>25depth5 ~

ct,25depth4

~

~

Collon

stand

"'

hole

"'

_ ',.;.

/ N

-

401

0.2

406

-

/

387

266

4 !

~

l

j-

:

4-<t>B

118

'

t

~

~

<t>50

R1O

~

-

~

i......rreadleunit

o.

...

~

st

] 0

30

st

1

mounting hole

'

N

,.)-

175

--...

'-

~

I

~Gas

damp

er~

0

' :

N

4

_R

1

O

•

t hole :

"'

•

<D

¢6

5

N

;;!

, st!

R10

\&i

Operation

ci

0

~

\ 4-

<t>B

panel .,

....

<D

N

N

CO

0

co

rd

ho

le

~

CO

, 0

'

"'

<D

~

I 2-

<t>2

dep

th

2N

"'

N

123

1

17

<t>9

:

o-;

~

:

"'

I

- - -

'---

~

.,I

4-

¢37.5

deoth5.5

-

L

......,

g)

"/

""-

_µi_

"'

21

;!:

"'

483

~

262

y

3

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...