8. TROUBLESHOOTING

8.

TROUBLESHOOTING

• Please check the following points before calling for repairs

or

service.

• If the following remedies do not fix the problem, turn off the power switch and consult a qualified technician or the place of

purchase.

AcAur10N

Turn off the power switch and disconnect the power cord before carrying out troubleshooting.

If

the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

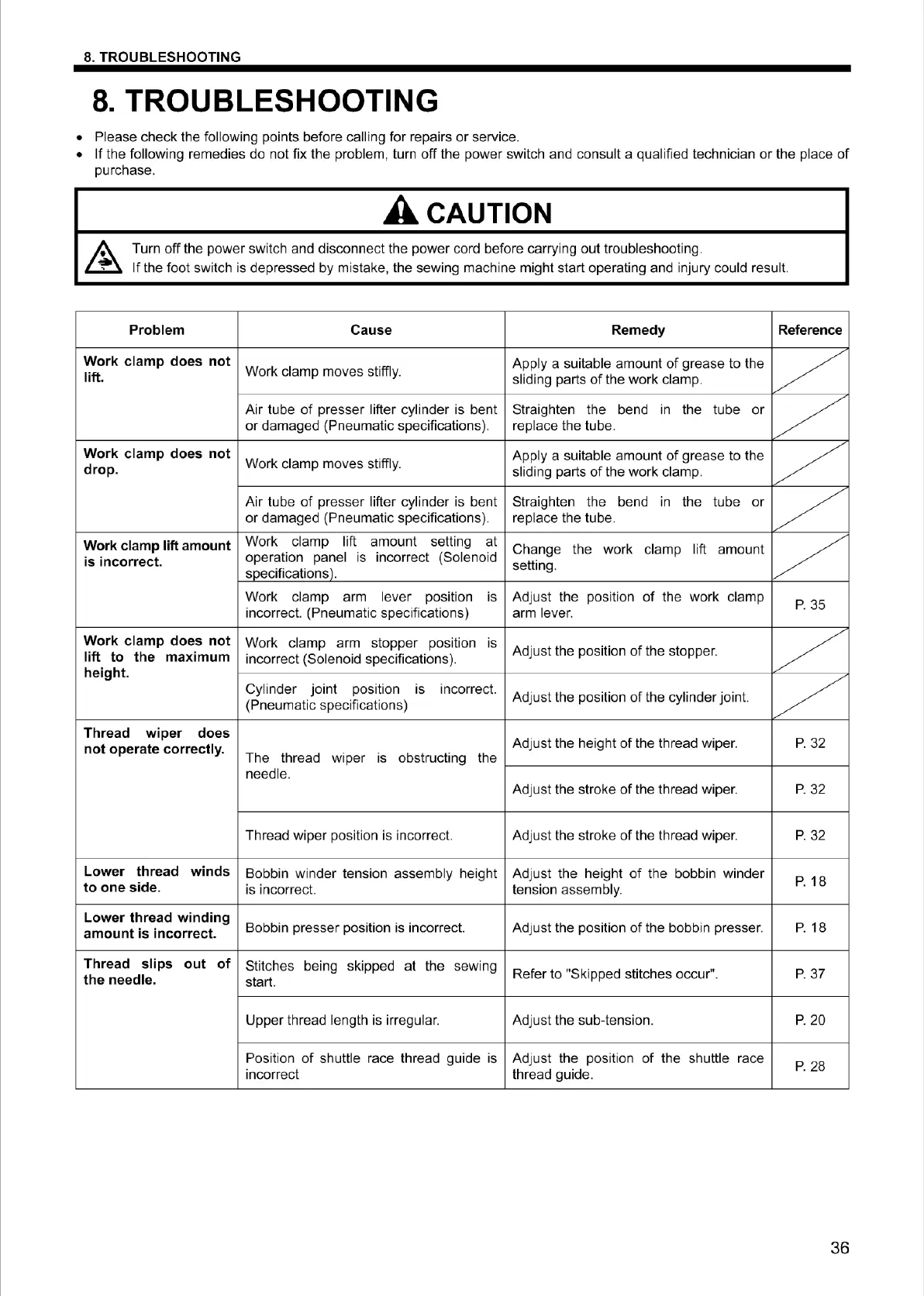

Problem Cause Remedy Reference

Work clamp does not

Work clamp moves stiffly.

Apply a

su

itable amount

of

grease to the

/

lift.

sliding parts

of

the work clamp.

A

ir

tu

be

of

presser lifter cylinder is bent Straighten the bend in the tube

or

/

or damaged (Pneumatic specifications). replace the tube.

Work clamp does not

Work clamp moves stiffly.

Apply a

su

itable amount

of

grease to the

/

drop.

sliding parts

of

the work clamp.

Air tube

of

presser lifter cylinder is bent Straighten the bend in the tube or

/

or damaged (Pneumatic specifications). replace the tube.

Work clamp lift amount

Work clamp lift amount setting at

Change the work clamp lift amount

/

is incorrect.

operation panel is incorrect (Solenoid

setting.

specifications).

Work clamp arm

lever

position is Adjust the position

of

the work clamp

P.

35

incorrect. (Pneumatic specifications) arm lever.

Work clamp does not

Work clamp arm stopper position is

Adjust the position

of

the stopper.

/

lift to the

ma

ximum

incorrect (Solenoid specifications).

height.

/

Cylinder joint position is incorrect.

Adjust the position

of

the

cy

linder joint.

(Pneumatic specifications)

Thread wiper does

not operate correctly.

Ad

ju

st the height

of

the thread wipe

r.

P.

32

The thread wiper is obstructing the

needl

e.

Adjust the stroke

of

the thread wiper.

P.

32

Thread wiper position is incorrect. Adjust the stroke

of

the thread wiper.

P.

32

Lower thread winds

Bobbin winder tension assembly height Adjust the height

of

the bobbin winder

P. 18

to

one side.

is incorrect. tension assembl

y.

Lower thread winding

Bobbin presser position is incorrect. Ad

jus

t the position

of

the bobbin presser.

P.

18

amount is incorrect.

Thread slips out

of

Stitches being skipped at the sewing

Refer

to

"Skipped stitches occur".

P.

37

the needle.

start.

Upper thread length is irregular. Ad

jus

t the sub-tension.

P.

20

Positi

on

of

shuttle race thread guide is Adjust the position

of

the shuttle race

P.

28

incorrect thread guide.

36

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...