11

06

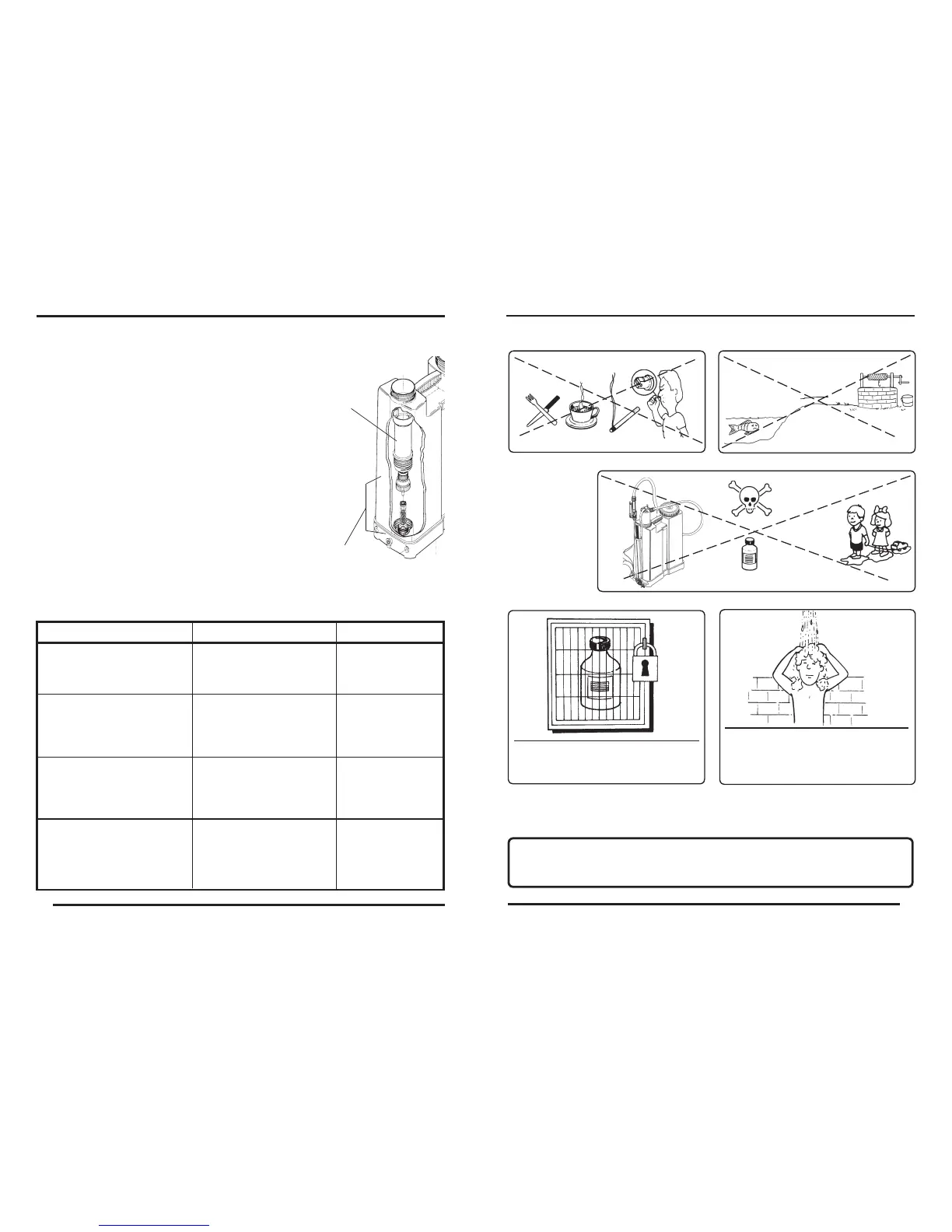

- Do not eat, drink or smoke while spraying.

- Do not pollute the environment.

- Keep the pro-

ducts out of reach

of children and

animals.

ATTENTION: The clothing used during the application must be washed separate

from other clothes of ordinary use.

- After nishing the spray application, take

a shower with plenty of water and soap.

- Put on clean clothes.

- Lock up the chemical products to prevent

untrained persons to handle them.

ATTENTION: In case of intoxication, see a doctor immediately and show

him the chemicals manufacturer's label.

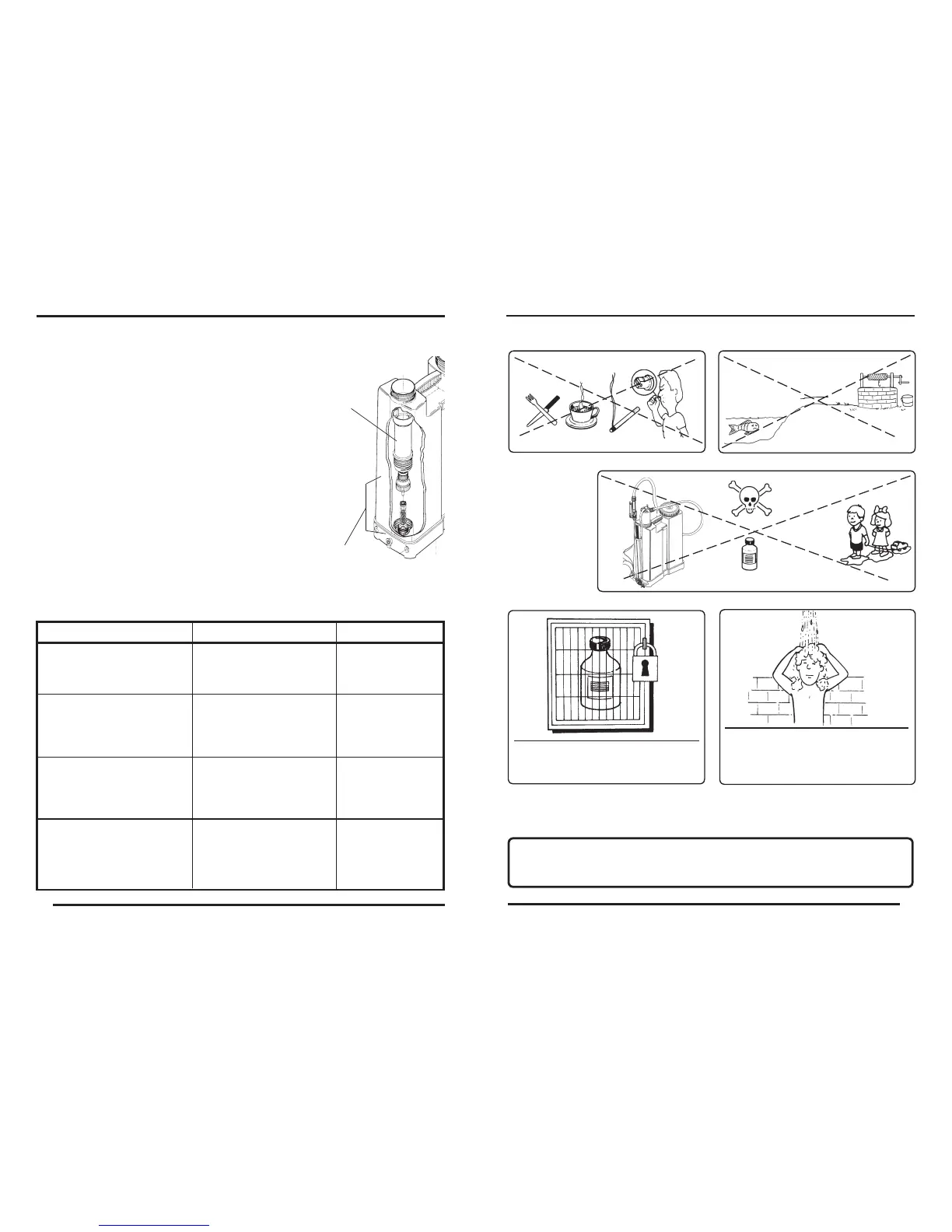

Cylinder valve

14- CYLINDER MAINTENANCE

DISASSEMBLING

- Remove the rod from the chamber top.

- Loosen the nut that fastens the chamber onto the tank.

- Push the chamber into the cylinder all the way.

- Turn the chamber 360° counter-clockwise and pull it out

of the tank.

- Remove the tank lid and the strainer.

- Inside the tank, unscrew the cylinder and take it out of the tank.

- Disassemble the cylinder valve using the maintenance wrench.

- Clean or replace the parts.

REASSEMBLING

- Install the valve in the cylinder and install it using the maintenance

wrench.

- Mount the cylinder on the sprayer and install it using the chamber

assembly as a wrench.

- Mount the chamber on the cylinder and retighten the nut.

- Install the rod in the chamber top.

Cylinder

15- TROUBLESHOOTING

- Put about 0.5 gallons of water in the tank.

- While operating the pumping lever, look into the tank to investigate the problem.

- Refer to the table and diagram below.

ilustrative gure

CORRECTIONS

Worn or dried out piston cup.

Replace or lubricate

the piston cup.

Leakage through the cylinder

upper part (1).

After pumping and pressurizing

the chamber, the lever it drops.

Cylinder valve (2) not sea-

ling properly due to wear or

impurities.

Clean or replace the

valve.

After pumping and pressurizing

the chamber, the lever rises

slowly when released.

Chamber valve (3) not sea-

ling properly due to wear or

impurities.

Clean or replace the

valve.

PROBLEM

CAUSES

The lever is hard to pump and

the spray stops rapidly.

Air leakage through the nut that

fastens the hose to the chamber.

Drain all the liquid

from the chamber.

Tighten the nut.

Loading...

Loading...