- 24 -

INST 396 Jacuzzi® J-HN Series Heater V12-16

There is a risk of carbon monoxide poisoning or asphyxiation if vent and/or its components are not properly installed in

accordance with all manufactures instructions. The vent pipe joints must be sealed to prevent escape of flue gases. Verify that

all vent components from different manufactures are compatible. Follow all vent component manufactures instructions, all local

code requirements, and the requirements of the National Fuel Gas Code, NFPA 54 (for US

COMBUSTION AIR SUPPLY (INDOOR INSTALLATION)

In all indoor installations, including garages, utility rooms, and outdoor enclosure, ONLY the fuel gas (Nat Gas or Propane) is

delivered under pressure up to the pool heater. The air (oxygen) required for clean combustion is drawn into the heater from the

air surrounding the heater. The air supplying the heater must in turn be pulled into the room through vent openings between the

room and either the air (atmosphere) outside the building, OR from other areas of the building that the room (housing the heater)

is connected with.

BECAUSE OF CURRENT, MODERN HIGH ENERGY EFFICIENT (TIGHTLY SEALED) CONSTRUCTION IT IS STRONGLY

RECOMMENDED THAT THE INSTALLATION ONLY DEPEND ON AIR FROM OUTSIDE OF THE BUILDING.

Two equally sized separate vent (louvered or grilled) openings are required for the room.

a) One room vent opening in located within 1 foot (300mm)of the rooms ceiling.

b) The second room vent opening is located within 1 foot (300mm) of the rooms floor.

c) The tables only allow for ventilation of the pool heater, if any other gas-fired appliances are installed in the same room the

size of the vent openings from the room must be carefully evaluated to account for the total load of all the gas-fired

appliances co-located with the pool heater, including the case of multiple pool heaters in commercial installations.

The use of two vent opening allows sufficient air to be brought into the room while allowing the room to breathe.

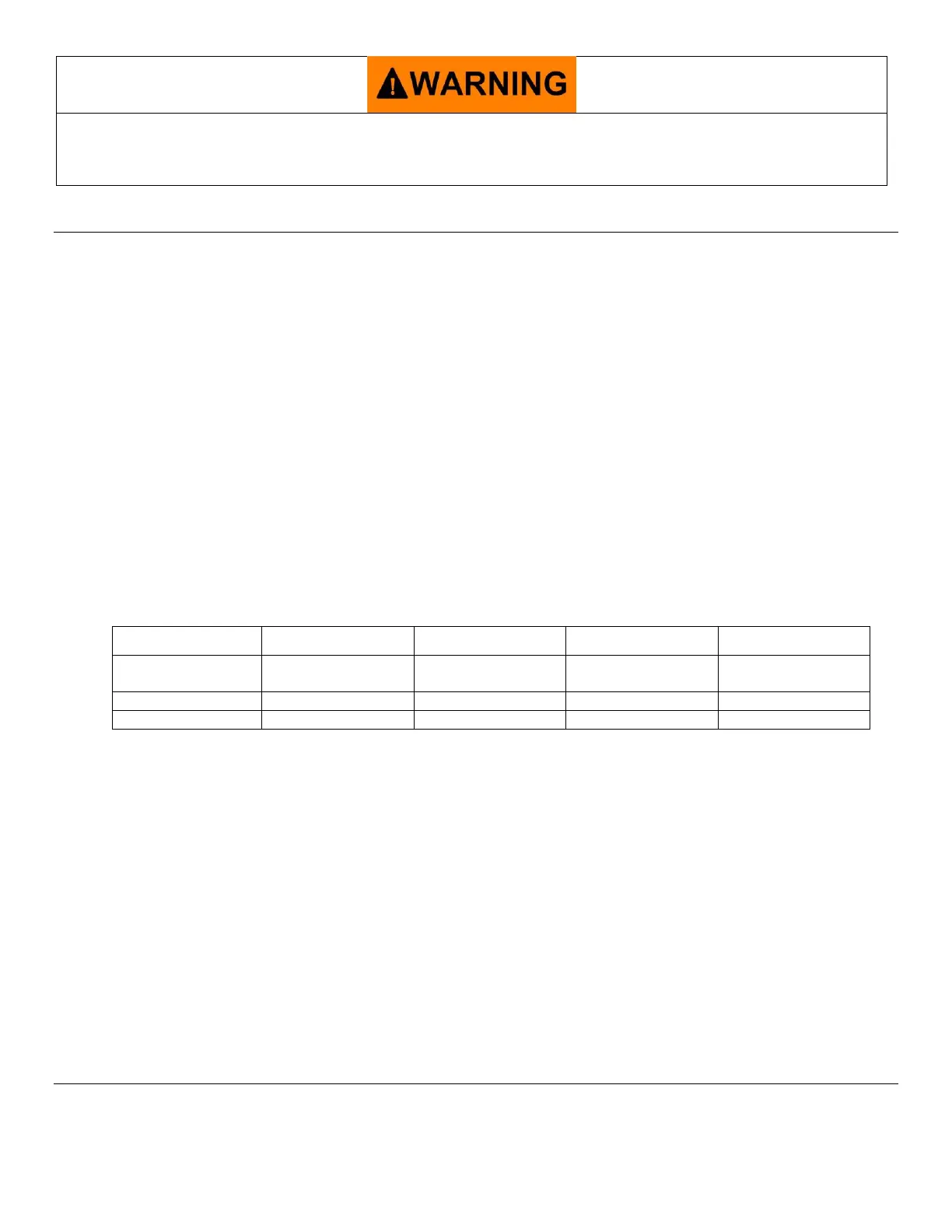

** NET FREE OPEN AREA (MINIMUM) FOR EACH OPENING, SQUARE INCHES (SQ Centimeters)

** (The area of the opening blocked by the louvers is deducted from totals

ALL AIR SUPPLIED FROM

INSIDE BUILDING

ALL AIR SUPPLIED

FROM INSIDE BUILDING

COMBINED AIR MIN,

OPENING

COMBINED AIR MIN,

OPENING

Combustion Air

Min. Opening

Ventilation Air

Min Opening

Combustion Air

Min. Opening

Ventilation Air

Min Opening

Note: Ideally the heater is situated near (within 25 feet) (7.6 meters)of the room vent openings, for ideal combustion and ventilation

air supply. In certain installations in commercial buildings or when the heater can only be installed far away from outside walls of the

building, it may be necessary to provide either passive air supply ducts leading from the outside of the building to near the heater or

it may even be necessary to provide for a powered air make – up ventilation system which used a blower to force air to proximity

of heater installation (Tjernlund is one manufacturer of Listed air make-up systems).

Loading...

Loading...