5

Always tighten hardware to these values unless a dierent torque or tightening procedure is listed for specic application. Fasteners must

always be replaced with the same grade as specied in the manual parts list. Always use the proper tool for tightening hardware. Make

sure fastener threads are clean and you start thread engagement properly. Use these values when tightening all bolts and nuts with

the exception of wheel nuts.

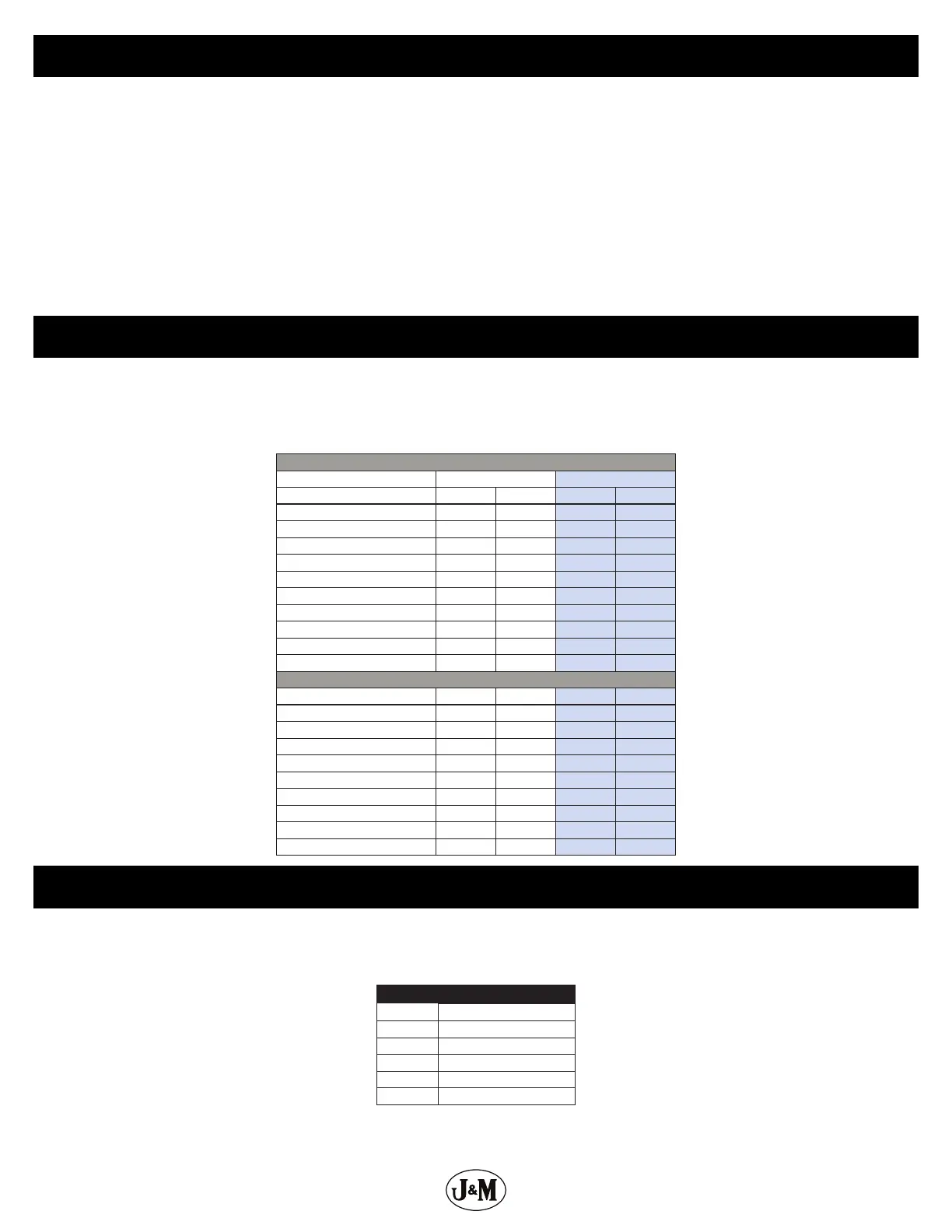

SAE Fasteners

Coarse Thread Series

Grade 5 Grade 8

Diameter and Pitch (Inches) Dry Oiled Dry Oiled

1/4”-20 8 ft-lbs 6 ft-lbs 12 ft-lbs 9 ft-lbs

5/16”-18 17 13 25 18

3/8”-16 31 23 44 33

7/16”-14 49 37 70 52

1/2”-13 75 57 106 80

9/16”-12 109 82 154 115

5/8”-11 150 113 212 159

3/4”-10 267 200 376 282

7/8”-9 429 322 606 455

1”-8 644 483 909 681

Fine Thread Series

Diameter and Pitch (Inches) Dry Oiled Dry Oiled

1/4”-28 10 ft-lbs 7 ft-lbs 14 ft-lbs 10 ft-lbs

5/16”-24 19 15 27 20

3/8”-24 35 26 49 37

7/16”-20 55 41 78 58

1/2”-20 85 64 120 90

9/16”-18 121 91 171 128

5/8”-18 170 127 240 180

3/4”-16 297 223 420 315

7/8”-14 474 355 669 502

TIGHTENING WHEEL NUTS: Standard 1/2” wheel studs and nuts should be tightened to torque 120 ft-lbs. During initial operation

of the header transport and then checked for proper torque after every 10 hours of use. Failure to do so may damage wheel nut seats.

Once seats are damaged, it will become impossible to keep nuts tight.

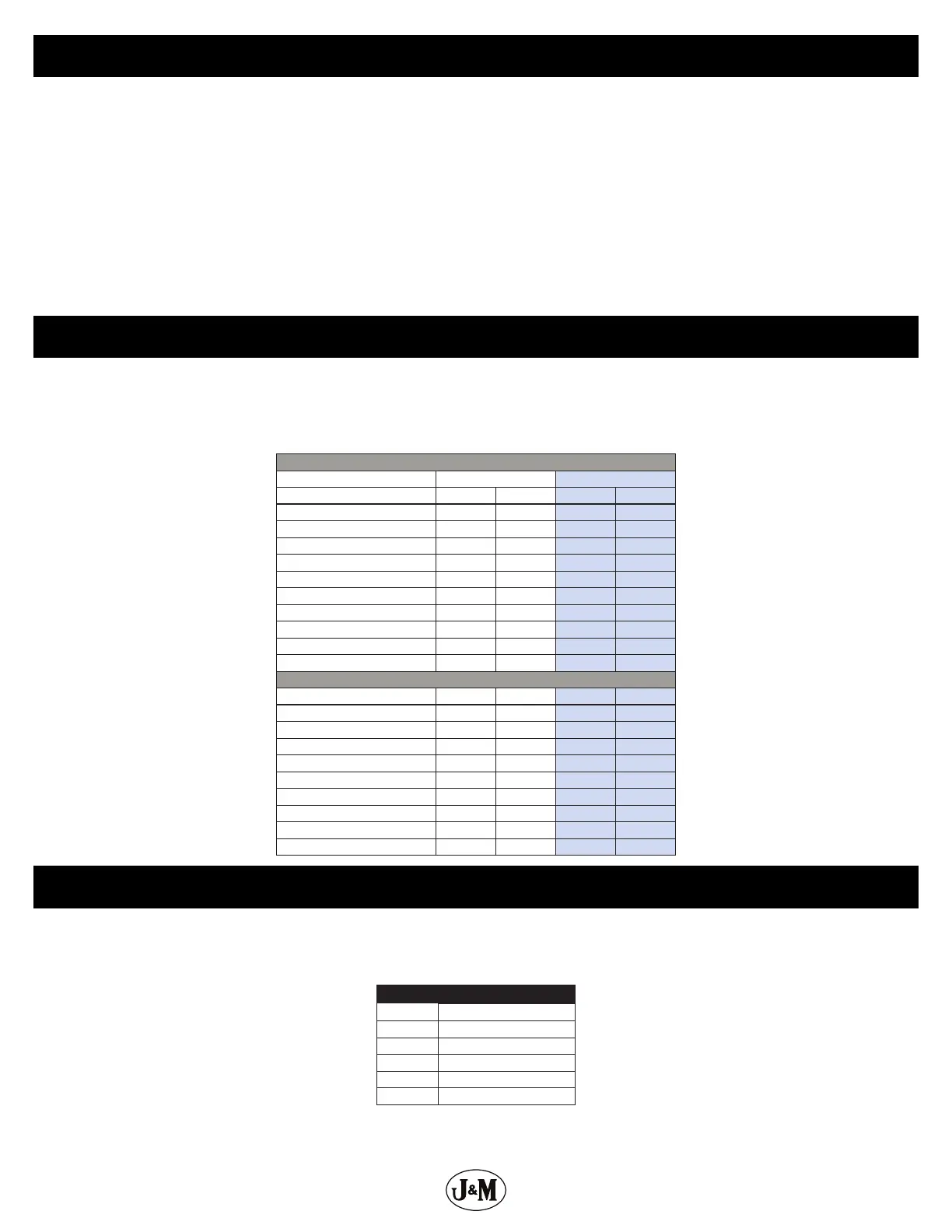

Stud and Wheel Nut Torque Specications

Always tighten hardware to these values unless a dierent torque or tightening procedure is listed for specic application. Fasteners must

always be replaced with the same grade as specied in the manual parts list. Always use the proper tool for tightening hardware. Make

sure fastener threads are clean and you start thread engagement properly. Use these values when tightening all studs and wheel

nuts.

Stud Tightening Torque

1/2”-20 120 ft-lbs

9/16”-18 170 ft-lbs

5/8”-18 300 ft-lbs

3/4”-16 400 ft-lbs

20mm 475 ft-lbs

22mm 640 ft-lbs

Safety Rules

Bolt Torque Chart

Make sure that the implement is fastened securely to the tractor by using the proper hich pin, clip and safety chains.

Before unhooking the implement from the towing unit, be sure to properly block the wheels to prevent the implement from moving.

Never overload the header transport. Overloading the header transport is dangerous and can cause extensive damage.

Do NOT exceed speeds in excess of 25 MPH. The header transport is designed for heavy loads at slow speeds. Also be sure slow moving

vehicle emblem is attached to rear of wagon.

IMPORTANT: Use caution when transporting. Be alert of the transport unit’s overall width when approaching obstacles, such as post signs

and poles, along the road. Check the transport width of the unit to ensure clearance before entering bridges.

COMPLY WITH ALL SAFETY WARNINGS AND CAUTIONS IN THIS MANUAL AND IN THE COMBINE OPERATOR’S MANUAL.

WARNING: BE SURE ALL LIGHTS ARE WORKING PROPERLY BEFORE HIGHWAY TRAVEL.

Loading...

Loading...