Janfire NH Burner Service Installation Manual 4.16.09 - Technical specifications are subject to change without prior

notice.

22(38)

6 NH Burner Set-up

6.1 NH Burner Draft Set-up and Control

Allow the burner to run for 15 minutes before performing combustion measurements.

Place the draft gauge in the hole of the boiler top door for combustion readings. Also drill a small pilot hole in

the venting system between boiler breeching and barometric damper location for additional combustion

measurements.

Adjust over fire and breeching draft by regulating the barometric damper to achieve the following draft settings:

Recorded draft readings at full firing rate:

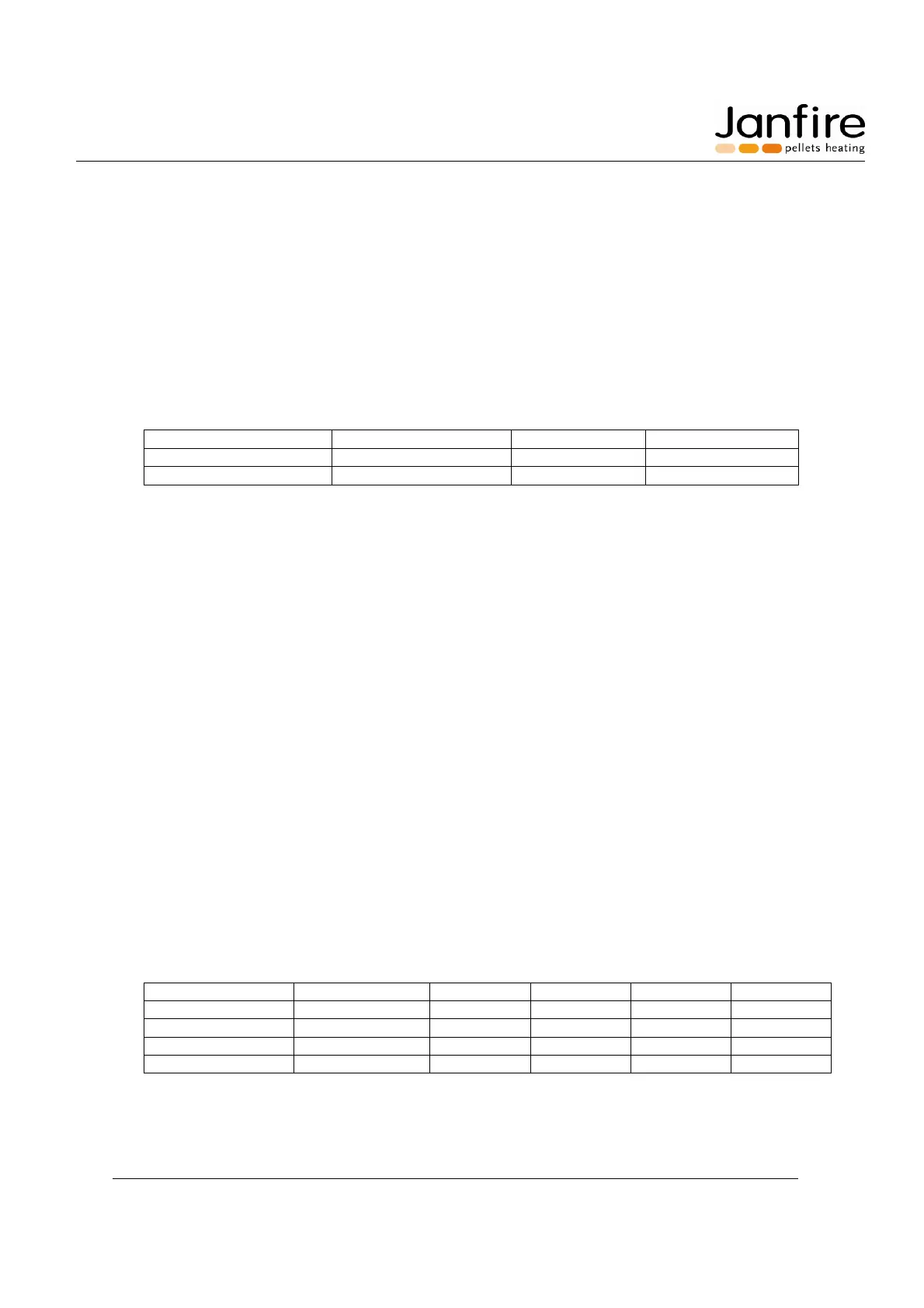

Test location Desired values Measured values Adjusted values

Boiler door (-.03 In WC)

Breeching draft (-.04 In WC)

Table 1. Full Fire Draft Readings

6.2 Combustion Adjustments

When adjusting combustion settings make sure that Volumetric weight density (4.5) and Energy density value

(4.6) are correct for the pellets used. These two settings control the amount of pellets being fed into the burning

cup during each feeding pulse.

It is very important to use the correct pellet data (Volumetric weight density and Energy density data) so the user

can easily change these settings depending on particular pellets used and still achieve good combustion.

Non-airtight boiler doors can result in incorrect readings, as the air, which affects combustion, dilutes the flue

gases. If you are unsure about the boiler’s airtightness, please visually inspect the flames in the firebox. The

flames should be yellow in color. Too much air (O2) or too little fuel results in a short flickering flame. Too little air

(O2) or too much fuel results in long, dark, sooty flames. The burner default factory settings are usually fine, but

small adjustments may be necessary.

Verify that pellet data (volume density and (ENHV) energy density) are correct, else adjust in the software.

Breeching draft measurement procedure:

1. Drill a hole in the boiler breeching, typically use a 3/8” drill.

2. Insert the flue gas analysis probe into the hole.

3. Allow combustion to run at the highest level for a few minutes.

4. Check the readings for CO2 and CO from the flue gas analysis.

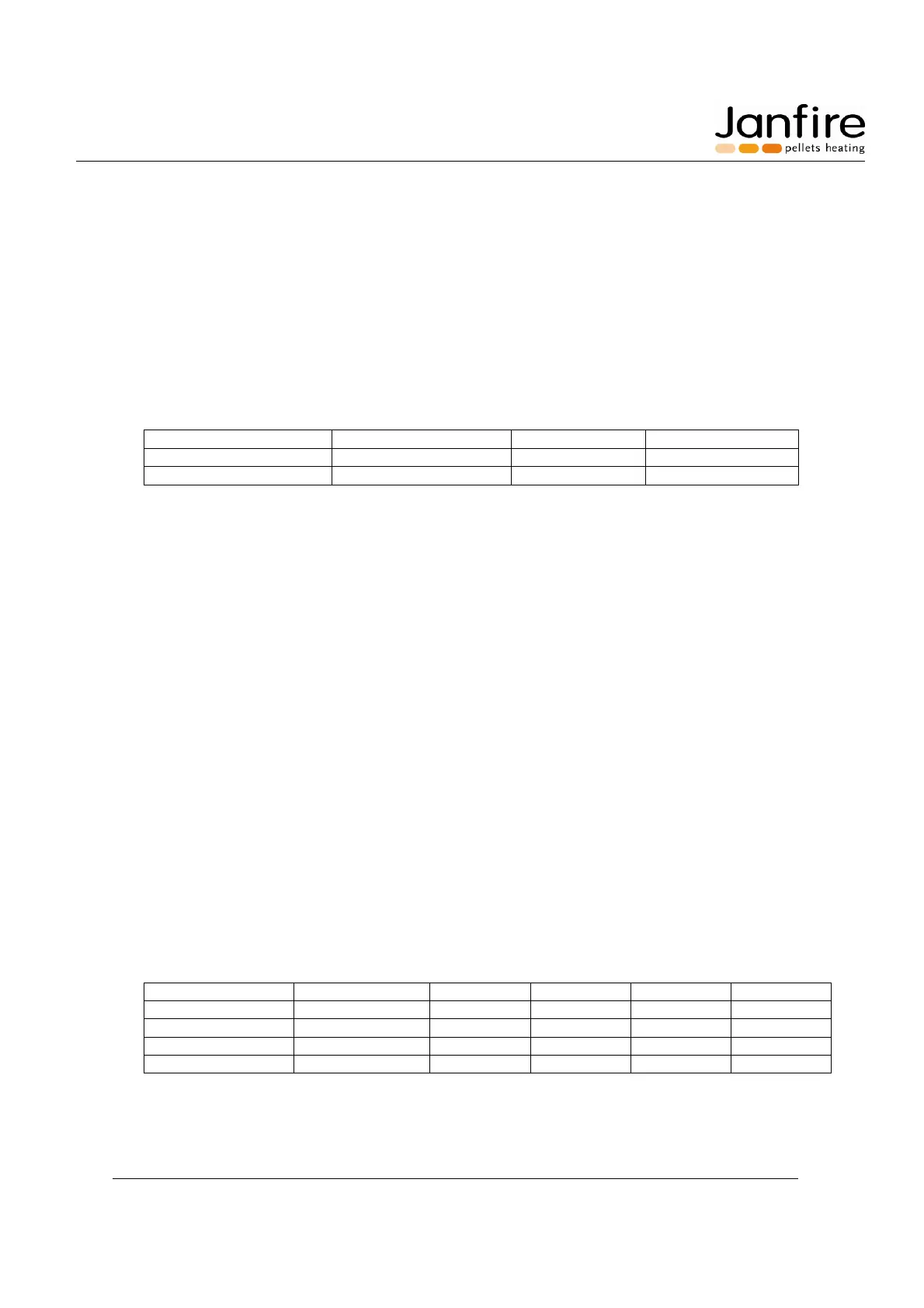

Breeching draft Desired values Test 1 Test 2 Test 3 Test 4

Dosage adjustment 0.80*

CO2 value 10 - 12%

O2 value 9 – 10%

CO value < 300 ppm

Table 2: Breeching combustion measurements: successive dosage adjustments

*The factory setting for dosage feeding time setting (service menu step: 23) is 0.80 sec. Adjust this value to

vary CO2 and O2 levels.

Loading...

Loading...