72

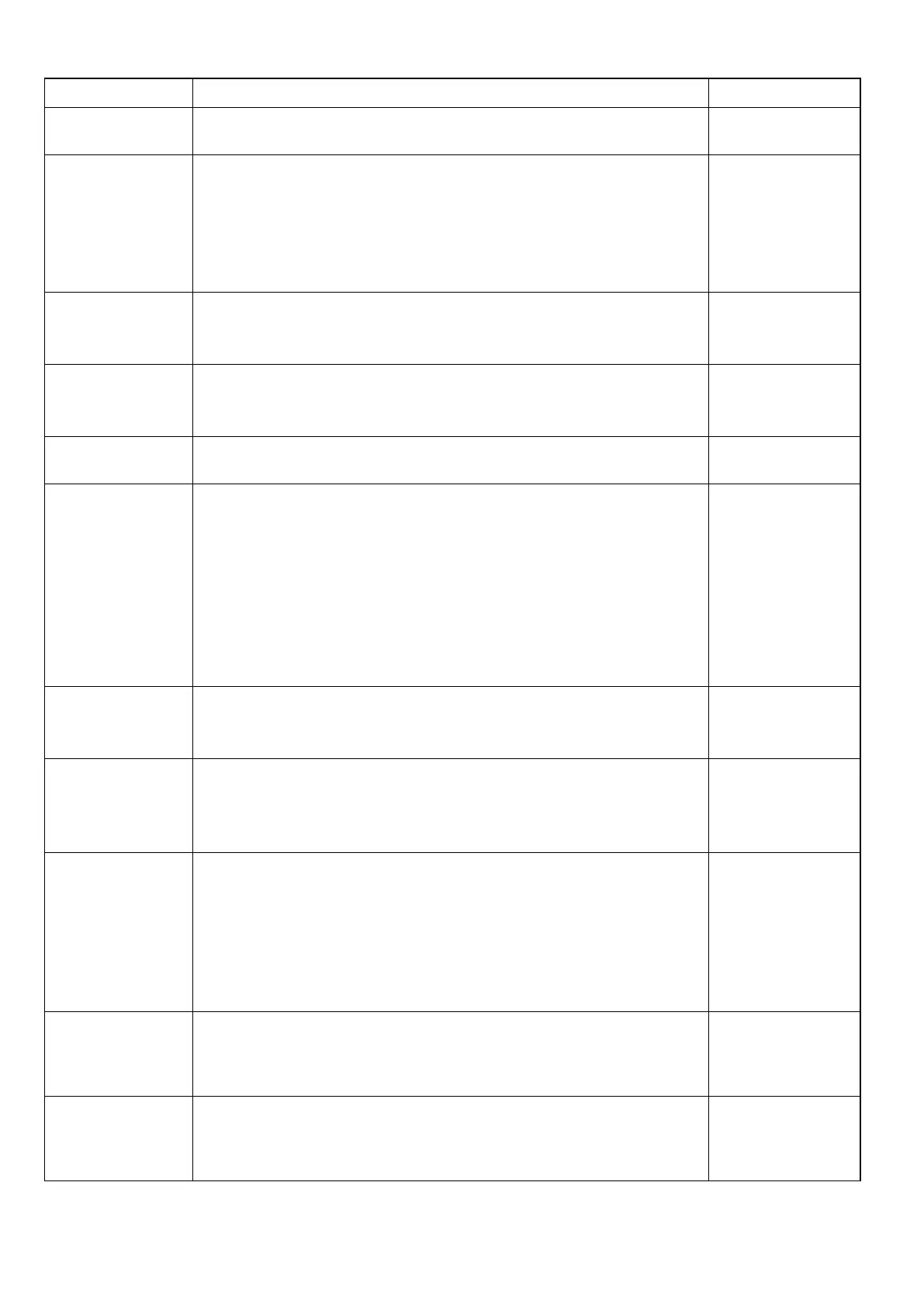

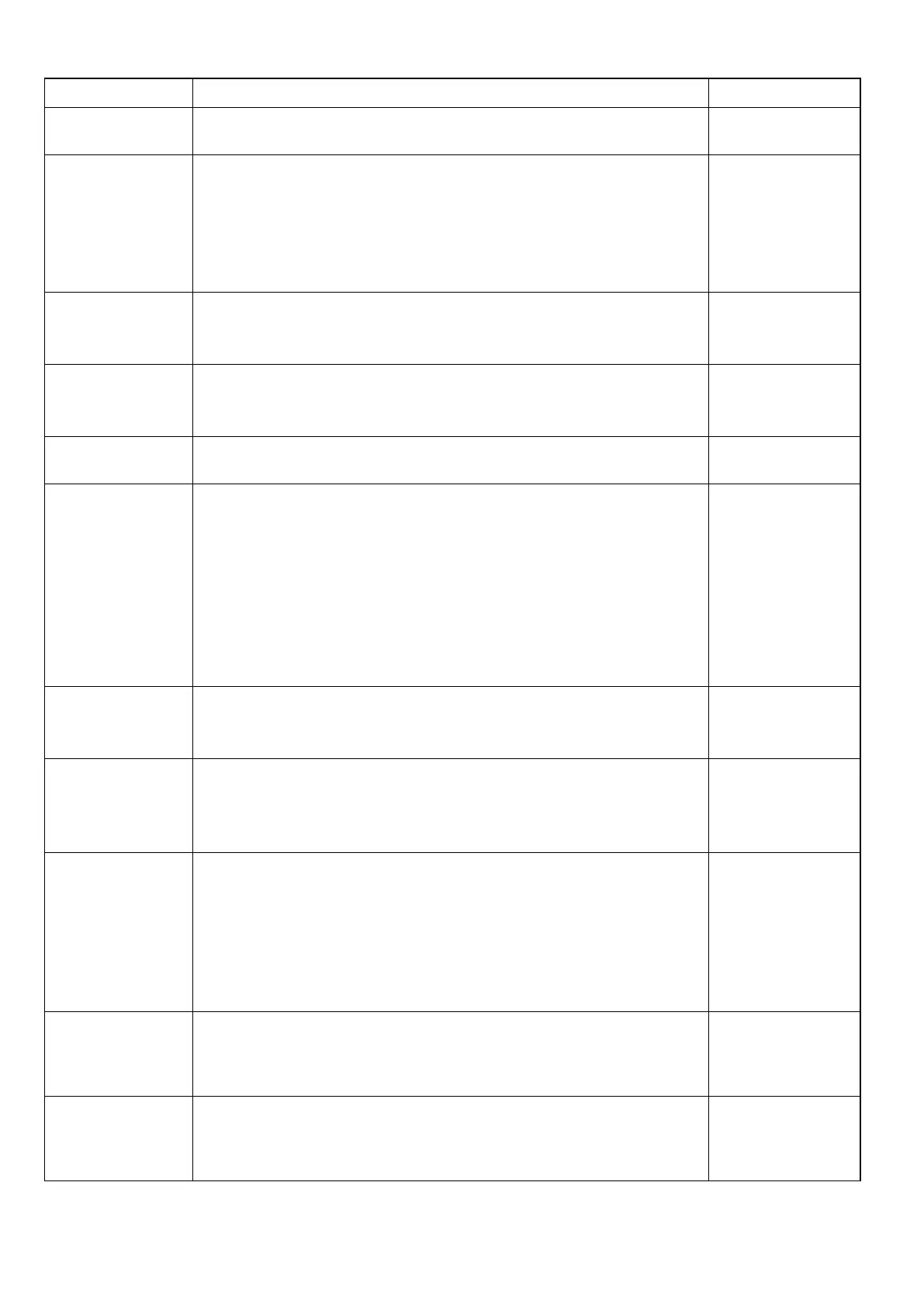

Troubleshooting

Condition Cause Reference

The machine is

noisy.

1. Thread is jammed in the hook area. See page 64.

The needle thread

breaks.

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is inserted incorrectly.

5. The needle thread was not set in the thread holder when embroidery

sewing started.

See page 12.

See page 57.

See page 14.

See page 14.

See page 23.

The bobbin thread

breaks.

1. The bobbin thread is not threaded properly in the bobbin holder.

2. Lint has been collected in the bobbin holder.

3. The bobbin is damaged and does not turn smoothly.

See page 11.

See page 64.

Replace the bobbin.

The needle breaks. 1. The needle is inserted incorrectly.

2. The needle is bent or blunt.

3. The needle clamp screw is loose.

See page 14.

See page 14.

See page 14.

Visual Touch

Screen is not clear.

1. The contrast of the screen is not adjusted properly. See page 55.

Skipped stitches 1. The needle is inserted incorrectly.

2. The needle is bent or blunt.

3. The needle thread is not threaded properly.

4. The needle is defective (rusted, burr on needle eye or tip).

5. The embroidery hoop is not set properly.

6. The fabric is not stretched tightly enough on the embroidery hoop.

7. A stabilizer is not being used.

8. The thread coming out from the needle eye is too short after auto

thread cutting.

See page 14.

See page 14.

See page 12.

Change the needle.

See page 22.

See pages 19-21.

See page 18.

See page 12.

The machine does

not run.

1. Thread is jammed in the hook area.

2. The machine is not plugged in.

See page 64.

See page 7.

Abnormal noise oc-

curs when the ma-

chine is switched

on.

1. Something is caught between the carriage and the arm. Remove the object.

The patterns are

distorted.

1. The fabric is not pulled tightly on the embroidery hoop.

2. The embroidery hoop is not xed securely.

3. The carriage is bumping into something around the machine.

4. The fabric is caught or pulled for some reason when sewing

embroidery.

5. A stabilizer is not used.

See pages 19-21.

See page 22.

Do not place any

obstacle around the

machine.

Reattach the fabric.

See page 18

Function keys do

not work.

1. Key positions are not adjusted properly.

2. The control circuit is not working correctly.

3. The bobbin winder spindle is in the winding position.

See page 55.

Contact the service

center or the store.

See page 10.

USB ash drive

does not work.

1. The USB ash drive is not inserted correctly.

2. The USB ash drive is damaged.

Insert the USB ash

drive properly.

Replace or format

the USB ash drive.

It is not abnormal for a faint humming sound to be heard from the internal motors.

The visual touch screen may become warm after several hours of continuous use.

Loading...

Loading...