Page: 15

FM-200® FILL MANUAL

Revision B

Document # DOC180

Issued: August 16, 2010

Revised: April 2, 2012

Section 4 Fill Procedure

4 FILL PROCEDURE

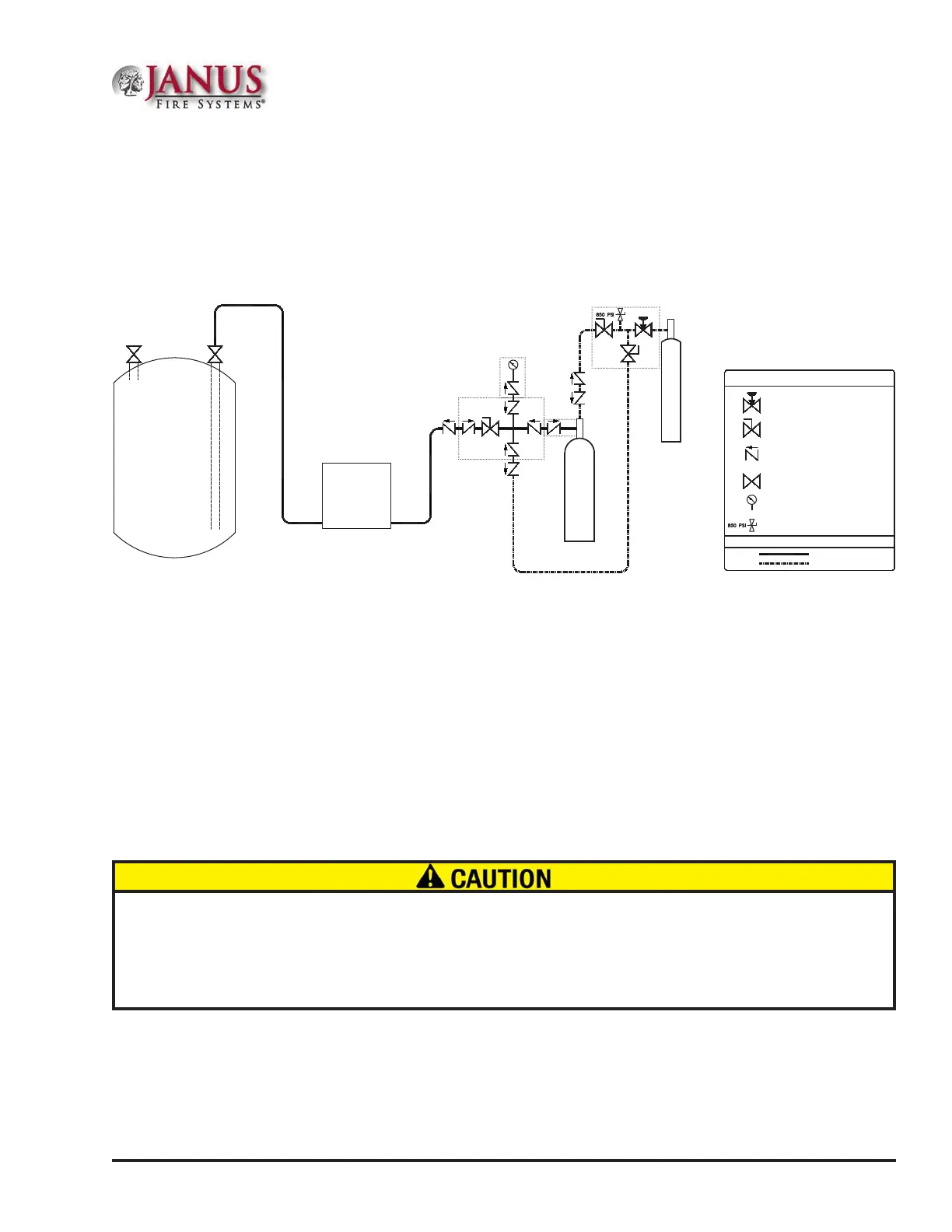

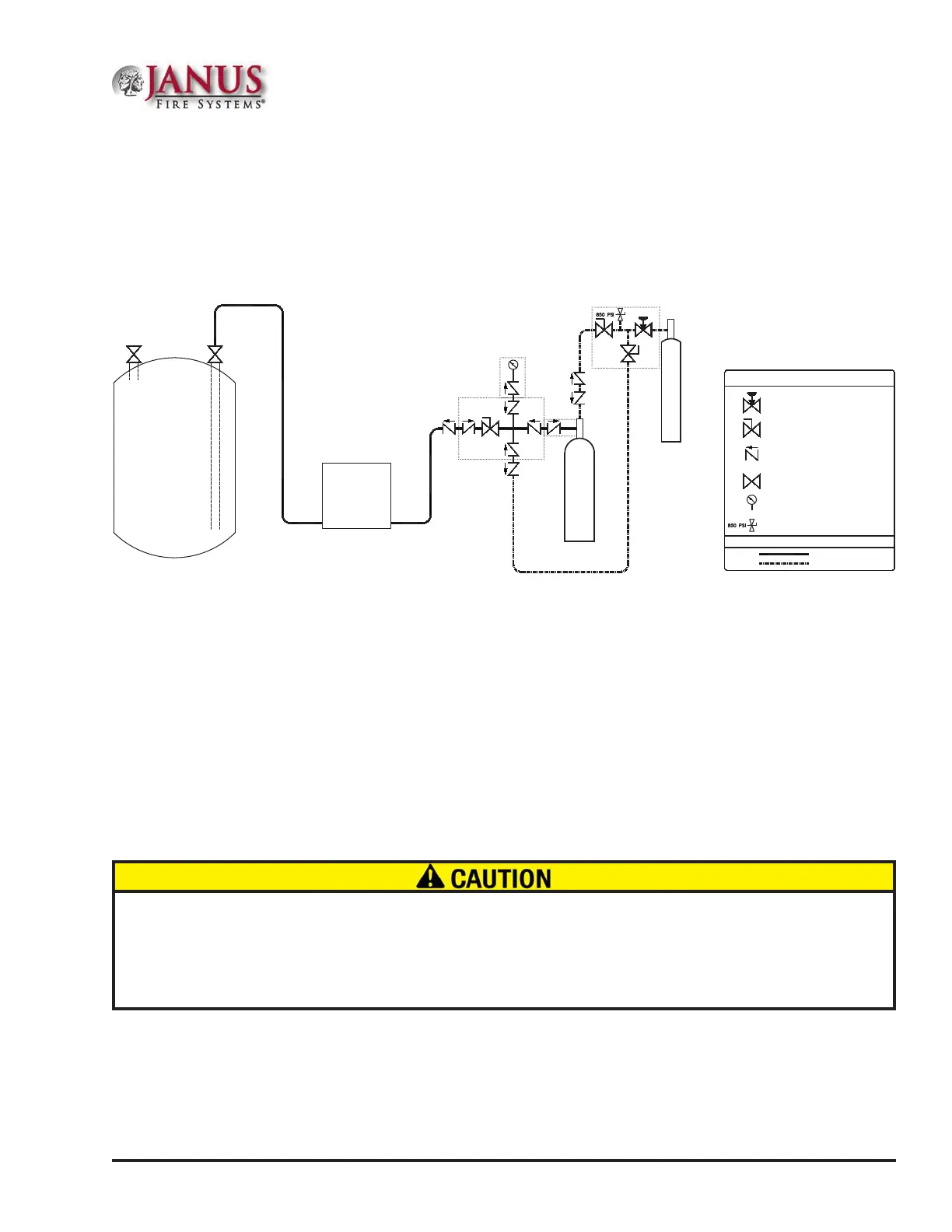

is section contains a step-by-step procedure for weighing, lling, pressurizing, and closing the cylinder

assembly. Refer to Figure 4 for a P&ID diagram that illustrates how each cylinder ll component connects

to the agent ll station, nitrogen supply, and cylinder assembly. Each component should be only installed

when indicated in the sections that follow.

SYMBOL LEGEND

PRESSURE REGULATING VAVLE

PIPING / HOSE LEGEND

NITROGEN LINE

AGENT FILL LINE

AGENT SUPPLY LIQUID LINE

AGENT SUPPLY VAPOR LINE

PUMP

IN

OUT

SYSTEMS

VALVE CLOSING LINE

CYLINDER PRESSURIZATION LINE

NITROGEN

CYL. FILL ASSY.

SUPPLY

TANK

CYLINDER

SUPPLY

FM-200

GAUGE ASSY.

FILL

ADAPTOR

REGULATOR/HOSE ASSY.

BALL VALVE

CHECK VALVE

SUPPLY TANK VALVE

PRESSURE GAUGE

RELIEF VALVE

4.1 Log and Weigh Empty Cylinder

• Record the serial number of the cylinder assembly in the appropriate section of the ll log. Record the

agent lot number from the supply of FM-200®, the ll station number from the agent ll station, and

the date of the ll in the appropriate sections of the ll log and cylinder label.

• Place the empty cylinder assembly on a calibrated scale. Record the weight displayed on the scale in the

appropriate section of the cylinder label and ll log as the empty weight. NOTE: e anti-recoil safety

device shall remain installed in the empty cylinder assembly during weighing. e ll adapter, cylinder

ll assembly, or valve closing adapter shall not be installed during weighing; do not include the weight

of any ll component in determining the empty cylinder weight.

Any trim components installed in the empty cylinder assembly prior to the initial weighing (including anti-recoil

safety device, pressure gauge, and/or low-pressure supervisory switch) shall be installed and included in all

proceedingweightmeasurementsduringthecourseofthellprocedure.Anytrimcomponentsnotinstalledon

the empty cylinder assembly during the initial weighing shall not be installed or included in any proceeding weight

measurements. Failure to maintain a consistent hardware base for weighing purposes may cause inaccuracy

when using these weights to determine the amount of agent contained in the cylinder assembly.

4.2 Agent Fill Procedure

NOTE: Prior to initiating the agent ll procedure, determine the ambient temperature of the lling location.

Compare this temperature to the values listed in Table B.1 located in Appendix B to determine the nal

cylinder pressure required to provide a cylinder pressure of 360 psig at 70°F.

Figure 4 Cylinder Fill P&ID Diagram

Loading...

Loading...