HIGH FREQUENCY The wire leads from the high frequency

driver are accessible from the rear of the enclosure. After

detaching these, the five Phillips-head wood screws that at

tach the driver’s clamp ring to the baffle board should be

removed. The driver is removed by loosening the screw at

the bottom of the clamp ring. When reinstalling the high

frequency driver, the two larger wood screws are inserted

through the holes nearest the base of the clamp ring. The

ring is positioned so that its base is directed towards the

bottom of the enclosure.

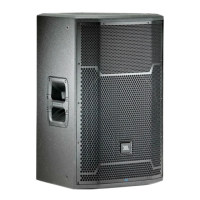

DIVIDING NETWORKS Detach the amplifier leads from the

network terminals. Remove the four screws from the corners

of each network mounting plate. Lift out each network and

remove the wire leads by gently pulling them through the

holes in the network mounting plate. Identify each wire so

that it can be replaced in the proper hole when the network

is reinstalled. Use the wiring diagram below to verify that

connections have been properly made. Each channel is color-

coded as shown.

8

REPLACEMENT Reverse the removal procedure to replace the

loudspeaker system components. Mounting screws should

be tightened evenly to avoid the possibility of frame warp-

age, and just enough to prevent air leaks between the com

ponents and the enclosure. Avoid excessive force.

Although JBL loudspeakers are extremely rugged, the

cone and other moving parts are subject to accidental

damage. Exercise extreme caution whenever using a

screwdriver or other tools in their immediate vicinity.

Whenever the horn is removed from the compression

driver, the mouth of the driver should be covered with

plastic tape. An intense magnetic field exists in the

mouth of the driver, and it is extremely important that

foreign objects such as iron chips, mounting hardware,

tools or other metal items be kept from the area.

JBL cabinetry represents the finest quality available in the THE PARAGON ENCLOSURE

high fidelity industry, uniquely styled and solidly constructed

to last a lifetime. Designed to complement the characteristics

of the loudspeaker components, the Paragon enclosure features

tight, wood-welded, lock-mitered joints and acoustic padding

to eliminate undesired resonance and warpage. Only the finest

compressed woods, furniture hardwoods and hardwood

veneers are used —carefully selected, skillfully prepared and

hand-rubbed to a rich, lustrous finish enhancing the natural

beauty of individual grain structure and color. Detail work

is obvious: hand-fitted joints are expertly closed; edge

veneering is flawless; scratches, dents, gluelines and other

defects are non-existent. Typical assembly line procedures

are avoided; each cabinet receives all of the personal atten

tion it must have before it can bear the JBL medallion —the

symbol for quality throughout the world.

Occasional dusting with a clean, soft cloth will maintain

the original beauty of the oiled walnut enclosure. Since

moisture cannot penetrate the oiled surface, most household

stains can be easily removed with a damp cloth. The surface

should be treated only with wax specifically formulated for

use on oiled finishes. Conventional furniture waxes, polishes

or cleaners are not recommended.

As the oil penetrates deeper and deeper into the walnut,

the finish may appear to be drying out. Many owners find it

desirable to re-oil the enclosure surface from time to time.

With each application, the beauty of the finish will become

more obvious, and a warm, rich patina will eventually be

obtained.

To re-oil the finish, use the JBL finishing oil supplied with

the Paragon or any one of the several clear oil finishing

preparations available through furniture or hardware outlets.

Apply a liberal amount of the preparation over the entire

finished surface of the enclosure. In ten to fifteen minutes

wipe off the remaining oil with a soft, clean, dry cloth. Small

9

Loading...

Loading...