51 - 3

Drive Head Maxtrac - Assembly

Note: The crown wheel and pinion are matched and should

be renewed as a pair if either one is damaged or excessively

worn. The two differential housing halves are also matched.

Do not use unmatched halves. If required, fit a new

crownwheel to the differential case half, torque tighten

crownwheel retaining bolts to 166 Nm 122 lbf ft; 17 kgf m).

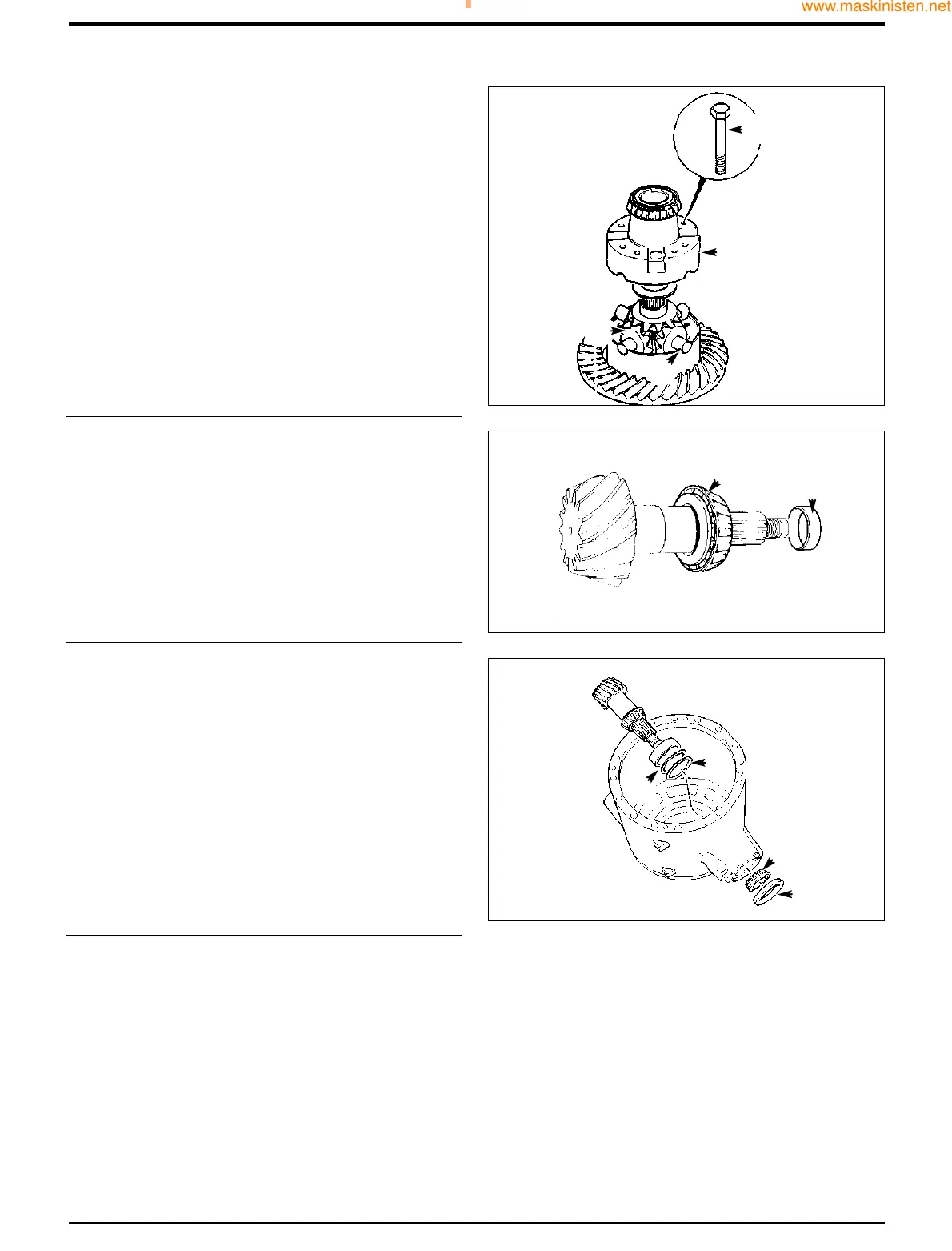

7 Assemble the differential gears and their spherical

washers into the bottom half housing. Fit the differential

bearing cones.

8 Position the top half housing onto the differential,

aligning the match mark letters (see Note above). Apply

JCB Threadlocker & Sealer to the threads of bolts, then

fit and torque - tighten to 56 Nm (42 lbf ft, 6 kgf m).

Check the gears for free rotation.

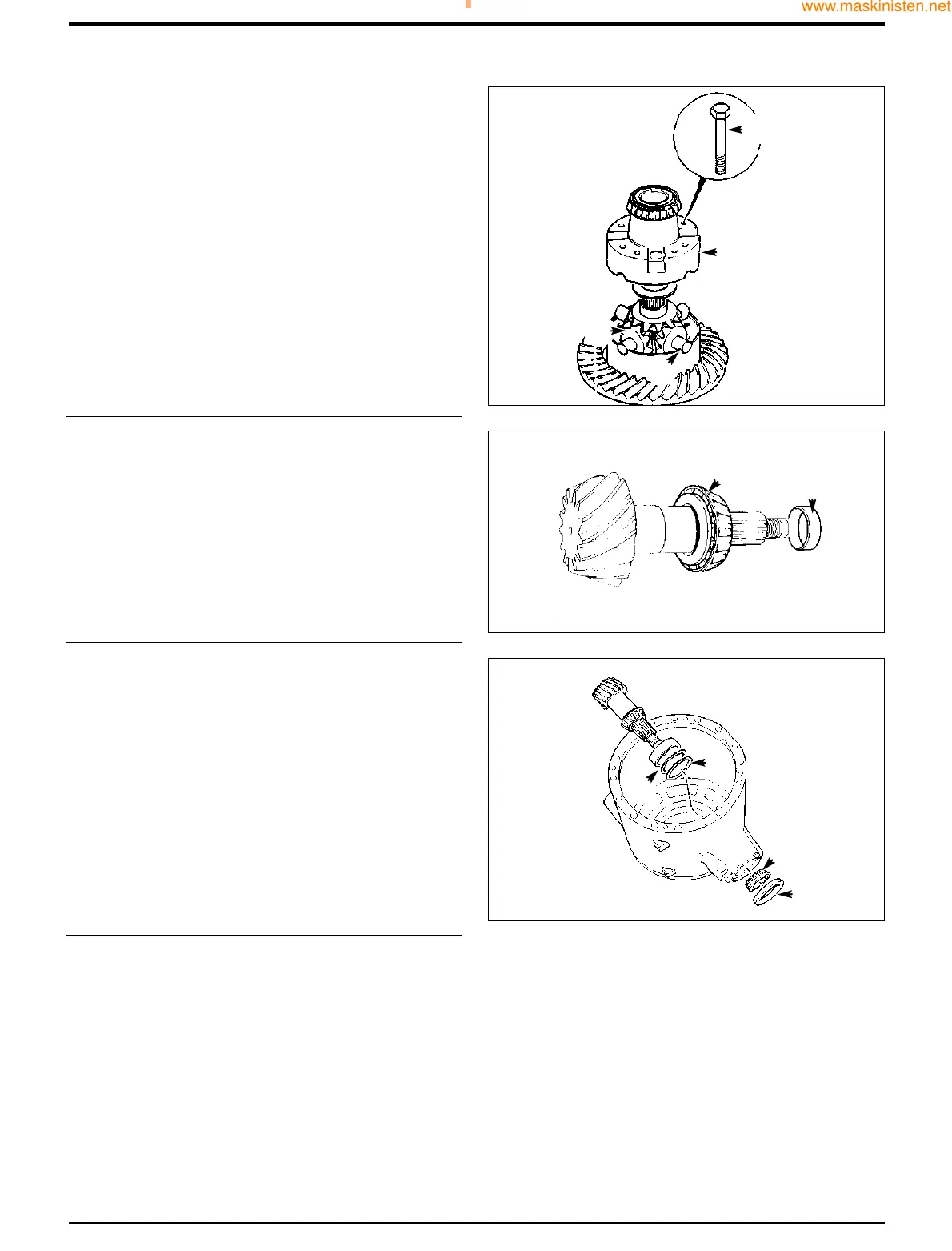

9 Fit the new inner bearing cone on to the pinion and the

largest available solid spacer Eg (14.20 mm) from the

solid spacer setting kit, refer to Service Tools - Axles.

Note: In the absence of the special tools required or the

correct size solid spacer it is acceptable to fit a collapsible

spacer, refer to Collapsible Spacer Assembly.

10 Determine the correct thickness required for the shims

10, refer to Pinion Depth Setting.

11 Fit shims 10 behind the pinion inner bearing cup. To

ensure the cup is fitted square, use a suitable puller

assembly. Do not use a hammer. Fit the outer bearing

cup.

12 Insert the pinion into its bore. (Before inserting, ensure

that the pinion matches the crownwheel. The code

numbers etched on the pinion end face and the

crownwheel perimeter should be the same.

13 Fit the pinion outer bearing cone. Do not fit the oil seal

at this stage.

Section F Transmission

9803/7130

Section F

51 - 3

Issue 1

Rear Axle

S256080

S256090

S256100

77

88

88

99

99

00

00

77

@@

@@

Loading...

Loading...