51 - 4

Drive Head Maxtrac - Assembly (cont'd)

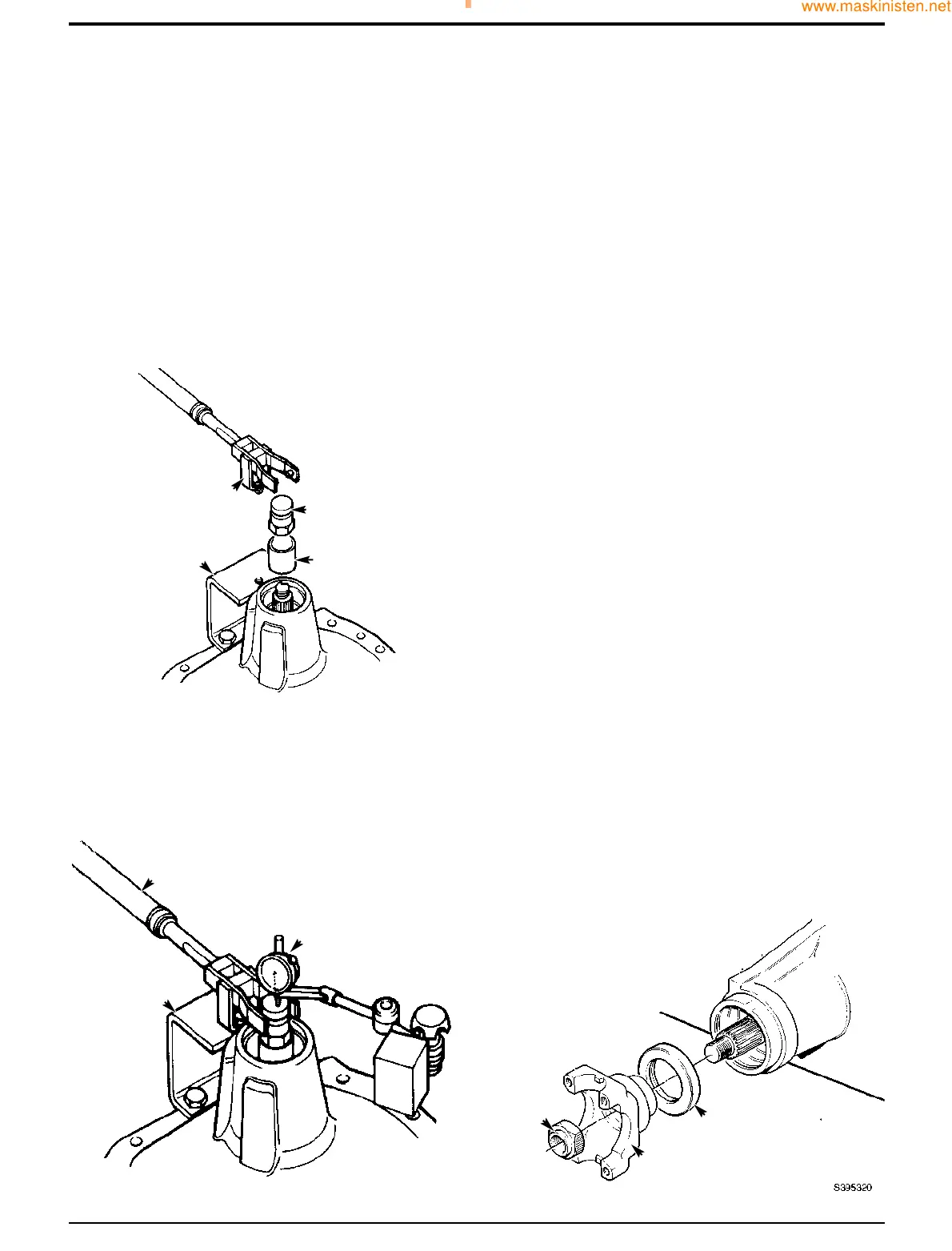

14 Fit special tool sleeve B and special pinion shaft

adapter C. Tighten adapter C to approximately 50 Nm,

making sure the pinion is free to rotate and there is end

float, this will prevent any damage to the bearing. If the

pinion is not free to rotate or there is no end float at this

stage check the bearing is fitted correctly. Also check

the correct size spacer has been fitted.

15 Fit special bracket D to the drive-head housing using

two M10 x 30 nuts and bolts. Fit special tool support

pillar E to bracket D so that the fork end engages in

adapter C. Ensure that fork E is centrally located on

adapter C. If necessary, re-align bracket D to suit.

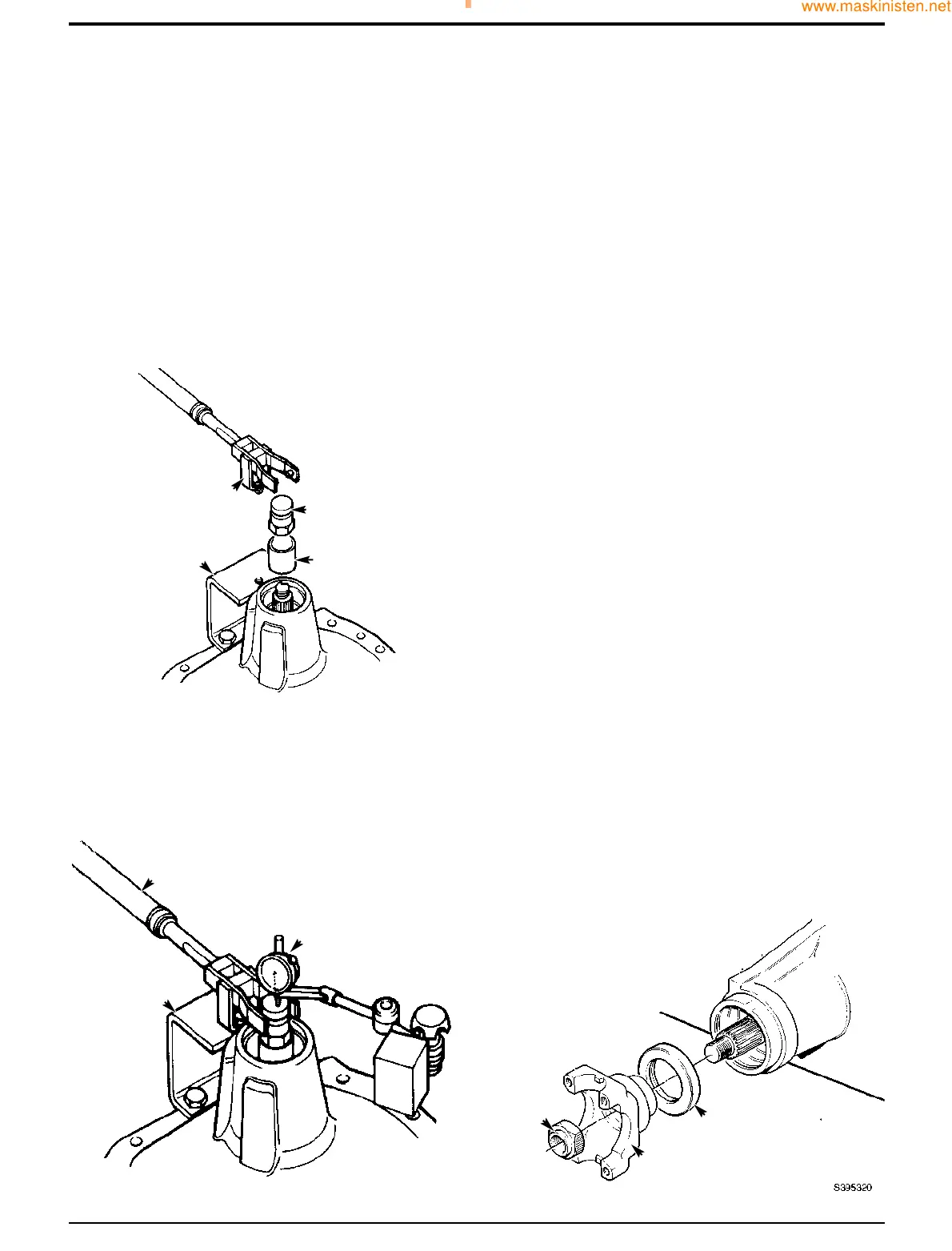

16 Fit dial test indicator (DTI) F. Ensure that the DTI is

mounted on the drive head and not on bracket D.

17 Set torque wrench G to 35 Nm (25.8 lbf ft) and measure

the end float while rotating the shaft.

Section F Transmission

9803/7130

Section F

51 - 4

Issue 1

Rear Axle

18 To select the right size solid spacer, subtract the end

float obtained at step 17 from the solid spacer size

(14.20 mm). Also subtract 0.04 mm to allow for

theoretical bearing tolerance and pre load. The result is

the size of spacer to be fitted from the solid spacer

setting kit. If there is no spacer of this size, fit the next

nearest size spacer, refer to Service Tools - Axles.

Example

Temporary spacer size 14.20

Subtract end-float 0.25

Total 13.95

Subtract tolerance & preload 0.04

Result 13.91

(No spacer available this size, use next nearest size

spacer i.e 13.900)

19 Remove sleeve B and temporary spacer. fit correct size

spacer from solid spacer setting kit, refer to Service

Tools - Axles. During removal take care to avoid

damaging the outer bearing.

20 Fit sleeve B. Tighten adapter C to no more than 50 Nm

to protect against bearing damage while spacer

selection is verified making sure the pinion is free to

rotate. Check there is no end float and pinion is free to

turn smoothly by hand. Remove adapter C and fit stake

nut K. Then check that rolling torque is less than 2.0

Nm. If the rolling torque exceeds 2.0 Nm, check that the

shaft has been assembled correctly.

Note: If the pinion is not free to rotate check the correct size

spacer has been fitted.

21 If rolling torque measured at step 20 is too high, fit the

next larger size spacer. If rolling torque is too low, fit the

next smallest size spacer. If a correct spacer is not

available from the range, check that drive head is

assembled correctly.

22 Remove adapter C and sleeve B.

23 Fit new oil seal H, grease between seal lips before

fitting. Fit coupling yoke J and NEW stake nut K.

FF

GG

348040

CC

BB

DD

348030

EE

DD

KK

HH

JJ

Loading...

Loading...