Fig 5

You can now position the belt in the

desired speed range.

Note:

The “High” speed range (1700-3900)

provides maximum speed, where as

the “Low” speed range (500-1200)

will provide maximum torque.

Close and lock the belt covers.

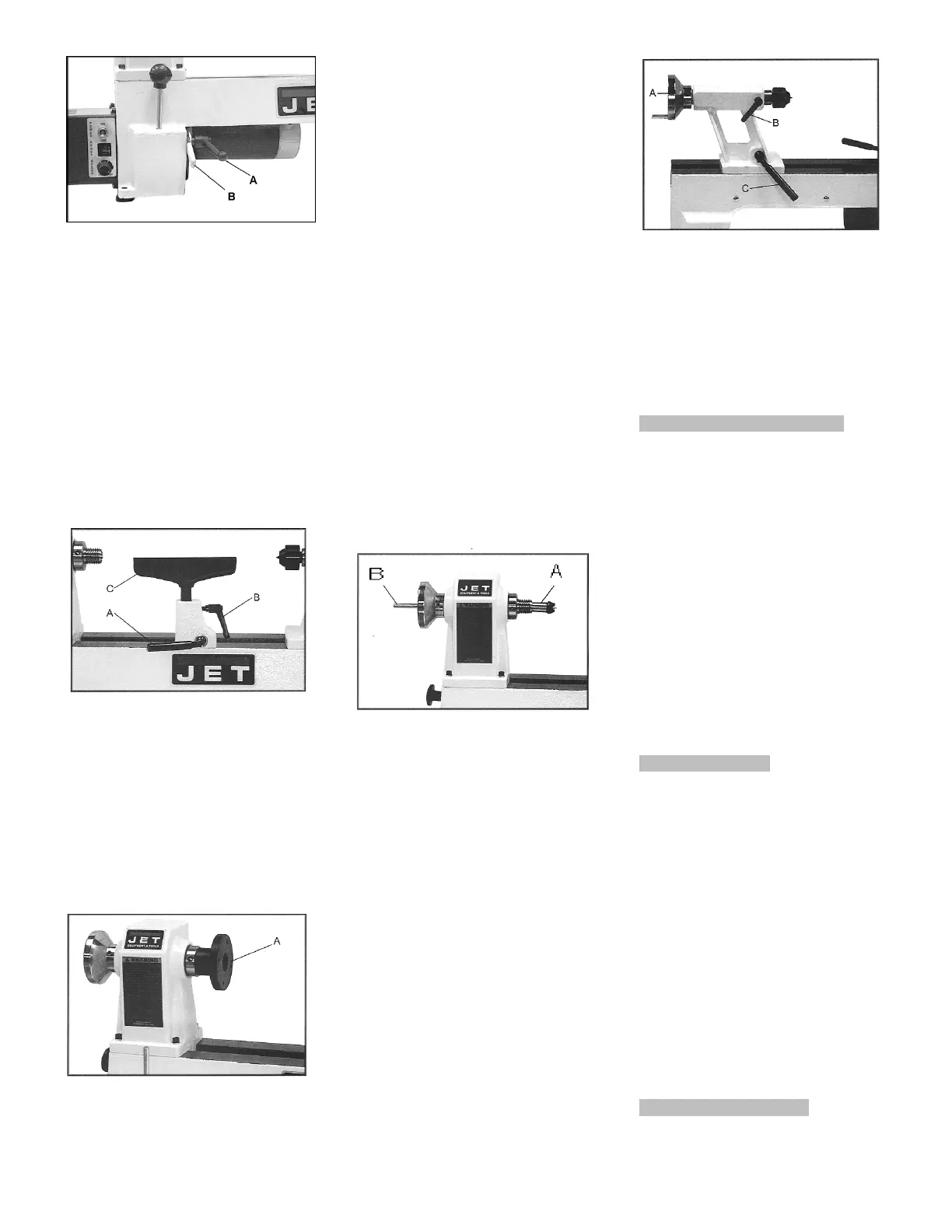

7.2 Adjusting tool rest

Position the tool rest (C, Fig 6) as

close to the workpiece as possible.

Tighten handle (A) to lock.

Fig 5

Set the height to appr. 3mm above

centre. Tighten indexable knob (B).

7.3 Installing work holding

Disconnect the machine from the

power source (unplug)

The face plate (A, Fig 7) screws on

the spindle nose thread.

Fig 7

Mount the workpiece directly to the

face plate using 4 brass wood screws

from the back. Be careful to use

screws short enough not to interfere

with the cutting process but long

enough to hold the workpiece securely

to the face plate.

If screw mounting is not allowed at all,

the work may be glued to a backing

block and the backing block screwed

to the face plate. A piece of paper in

the glue joint will prevent damaging

the wood when separated later.

Mount the face plate with the

workpiece already attached onto the

spindle nose thread and hand tighten.

Turn the workpiece by hand to see if it

rests securely and can be rotated

freely.

For face plate turning the tool rest is

set slightly lower than centreline.

Caution: always cut with your chisel

on the left half of the workpiece only.

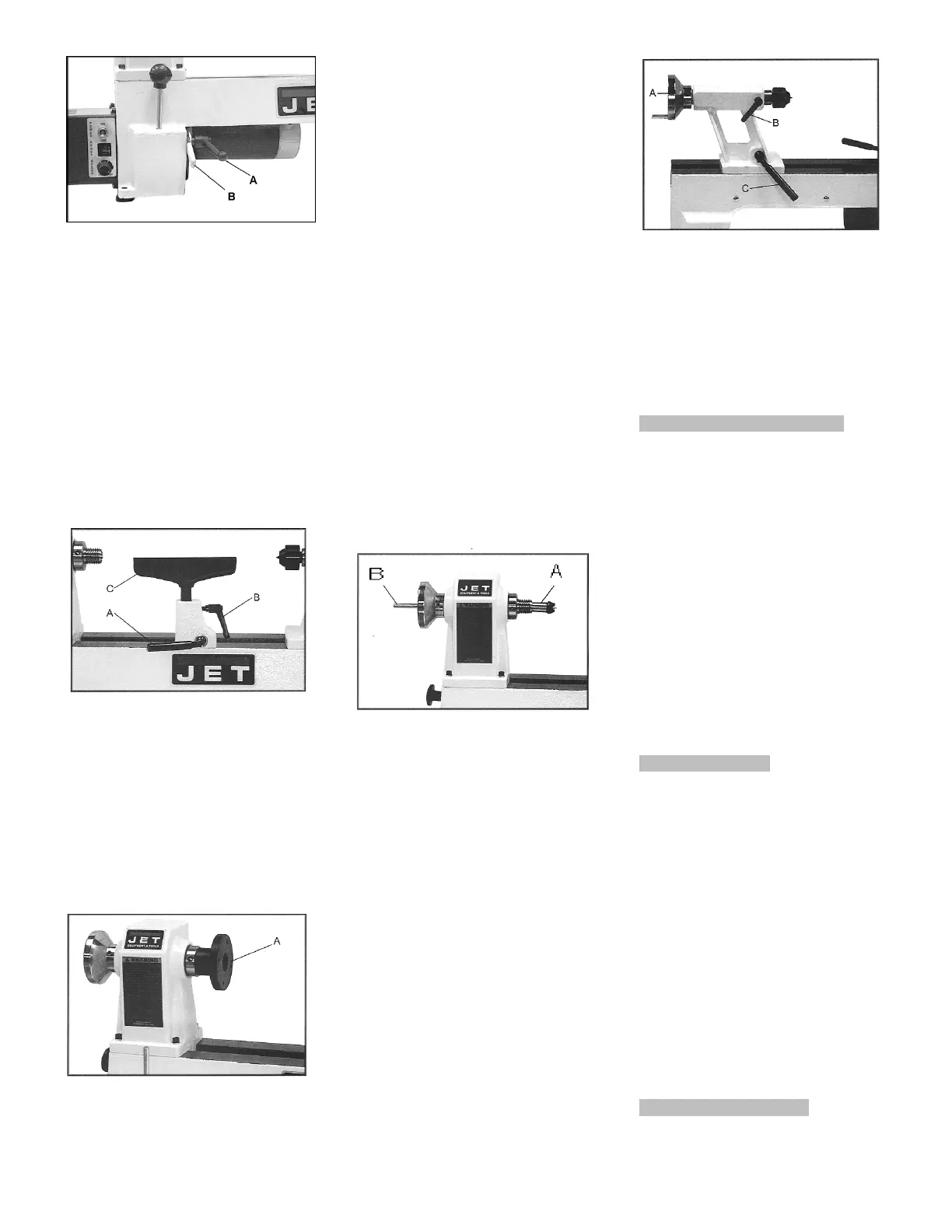

The spur drive centre (A, Fig 8) locks

into the spindle taper and can be

removed with the knockout rod (B).

Fig 8

Mount the workpiece between the spur

drive and the tailstock live centre.

Turn the tailstock hand wheel until the

live centre well penetrates the

workpiece. Reverse the hand wheel by

one quarter turn and lock the tailstock

spindle.

Turn the workpiece by hand to see if it

rests securely between centres and

can be rotated freely.

For turning between centres the tool

rest is set appr. 3mm higher than

centreline.

7.4 Adjusting tailstock

Turn the hand wheel (A, Fig 9)

clockwise to move tailstock spindle

forward. Lock spindle with the

indexable knob (B).

Fig 9

The handle (C) locks the tailstock in

position on the bed.

The live centre can be ejected by

turning the hand wheel counter-

clockwise.

The live centre pin can be removed to

allow deep hole drilling operations.

8. Maintenance and inspection

General notes:

Maintenance, cleaning and repair

work may only be carried out after

the machine is protected against

accidental starting by pulling the

mains plug.

Clean the machine regularly.

Inspect the proper function of the dust

collection daily.

Defective safety devices must be

replaces immediately.

Repair and maintenance work on the

electrical system may only be carried

out by a qualified electrician.

9. Trouble shooting

Motor doesn’t start

*No electricity-

check mains and fuse.

*Defective switch, motor or cord-

consult an electrician.

*Overload has reacted-

-Turn off machine power

-Push the reset button

-Then re-start the lathe.

Machine vibrates excessively

*Stand on uneven floor-

adjust stand for even support.

*Workpiece is not properly centred-

*The speed is too high-

10. Available accessories

Loading...

Loading...