length control operate automatically to provide coordinated start of the various parameters. At the

end of the weld, operation of the 9700T stop push-button initiates a controlled end of weld sequence

with downslope and wire and travel stop delays.

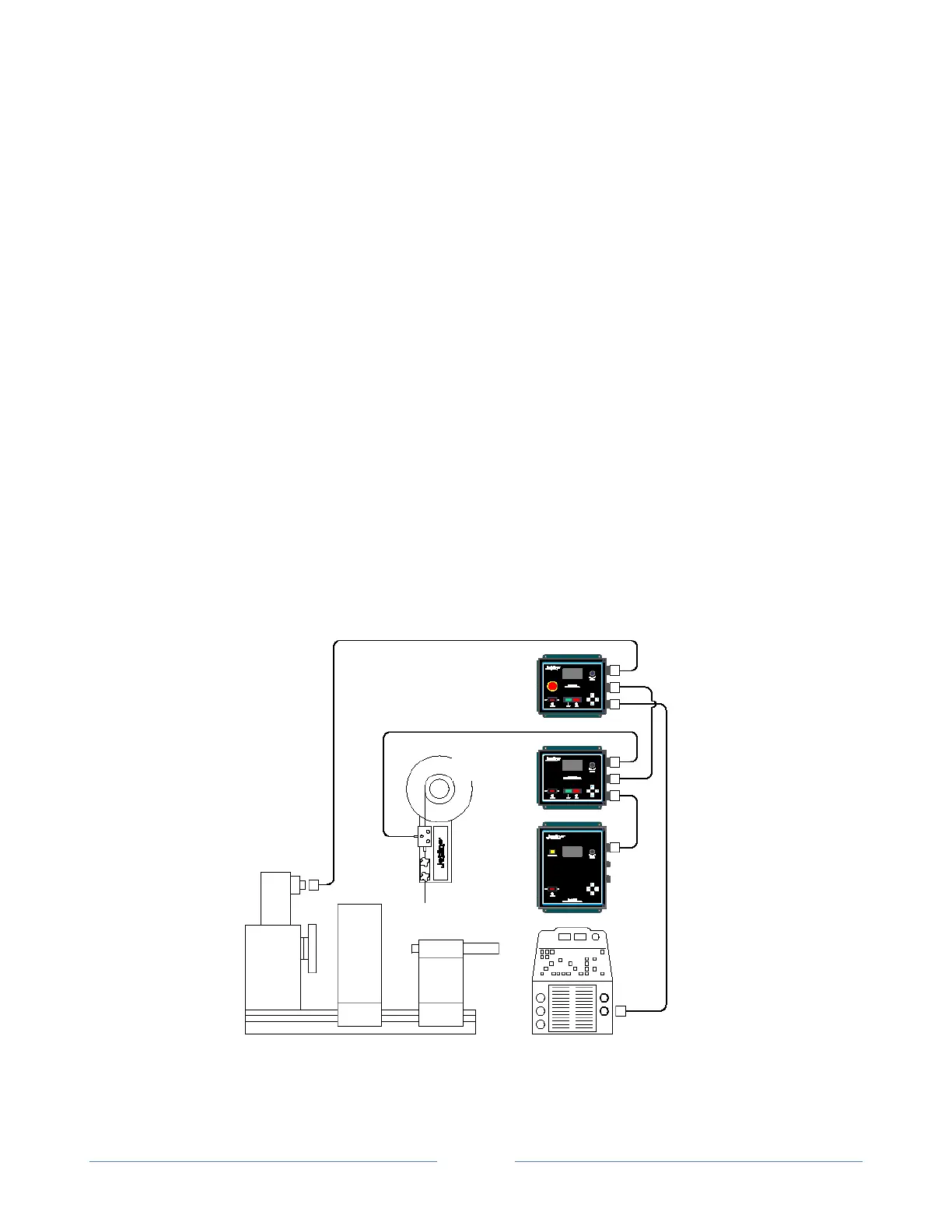

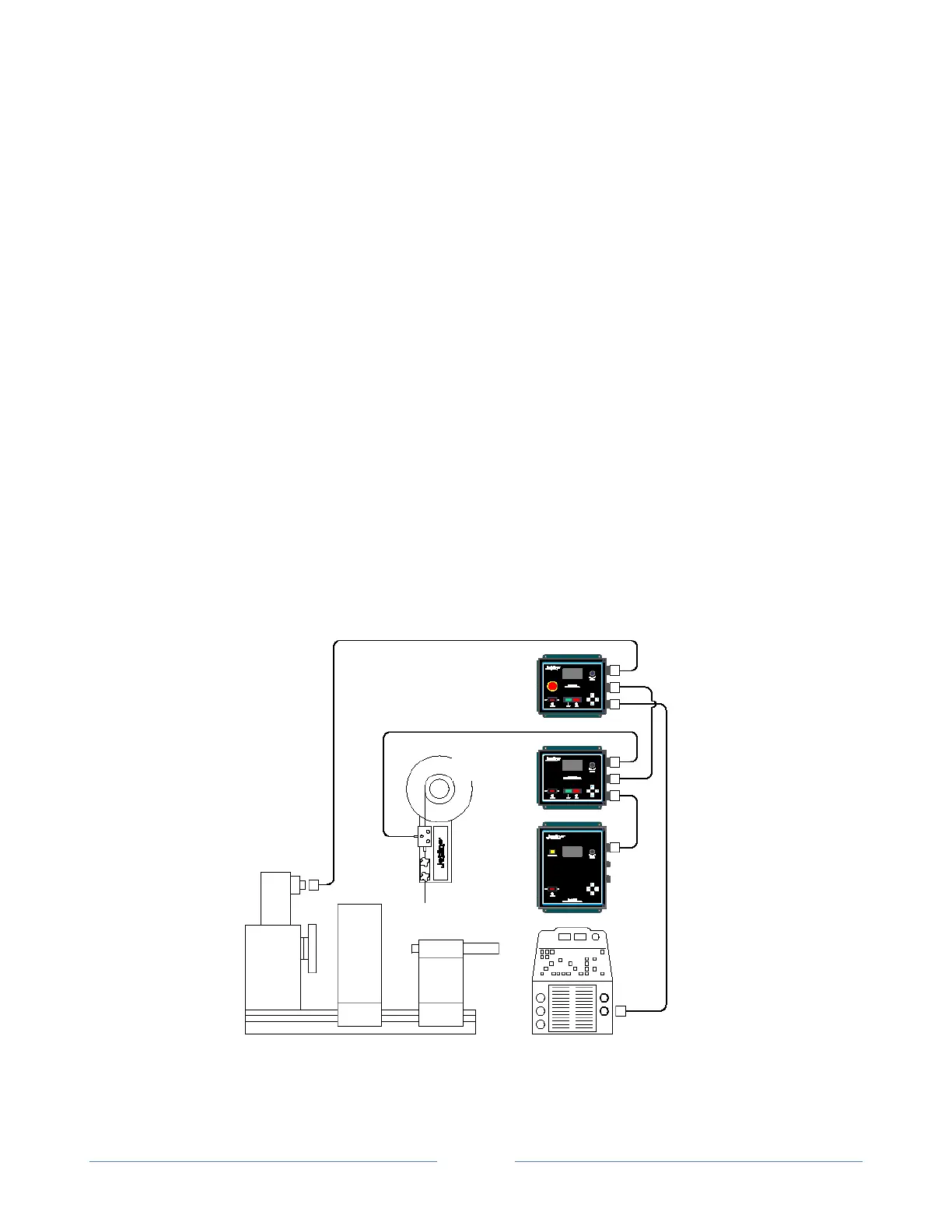

Required Connections and Cables showing old and new versions

:

9627 9700T

S1: 9627/9700T to welding power supply.

Cable: 9600S1-DX10-15 (For Miller)

Change to 9700S1-MLR28-15

S2: 9627/9700T to 9629/9700W control

Cable: 9600S2-S2-3

Change 9700S2-S2-3

S3: 9627/9700T to carriage drive motor.

Cable: Included with carriage

9629 9700W

S1: 9629/9700W to arc length control

Cable: 9600S2-ALC-3

Change to 9700S1-ALC74

S2: 9629/9700W to 9627/9700T control

Cable: 9600S2-S2-3 (same cable as above)

Change 9700S2-S2-3

S3: 9629/9700W to wire drive motor

Cable: Included with wire feed head

Figure 7: Typical Jetline System Interconnection Schematic for a GTAW with Wire feeder and Motion

Control. NOTE: Fixture shown is rotation but connection same for linear.

Welding Power

Source Remote

Connection

Loading...

Loading...