12 JLA Limited 113375-16

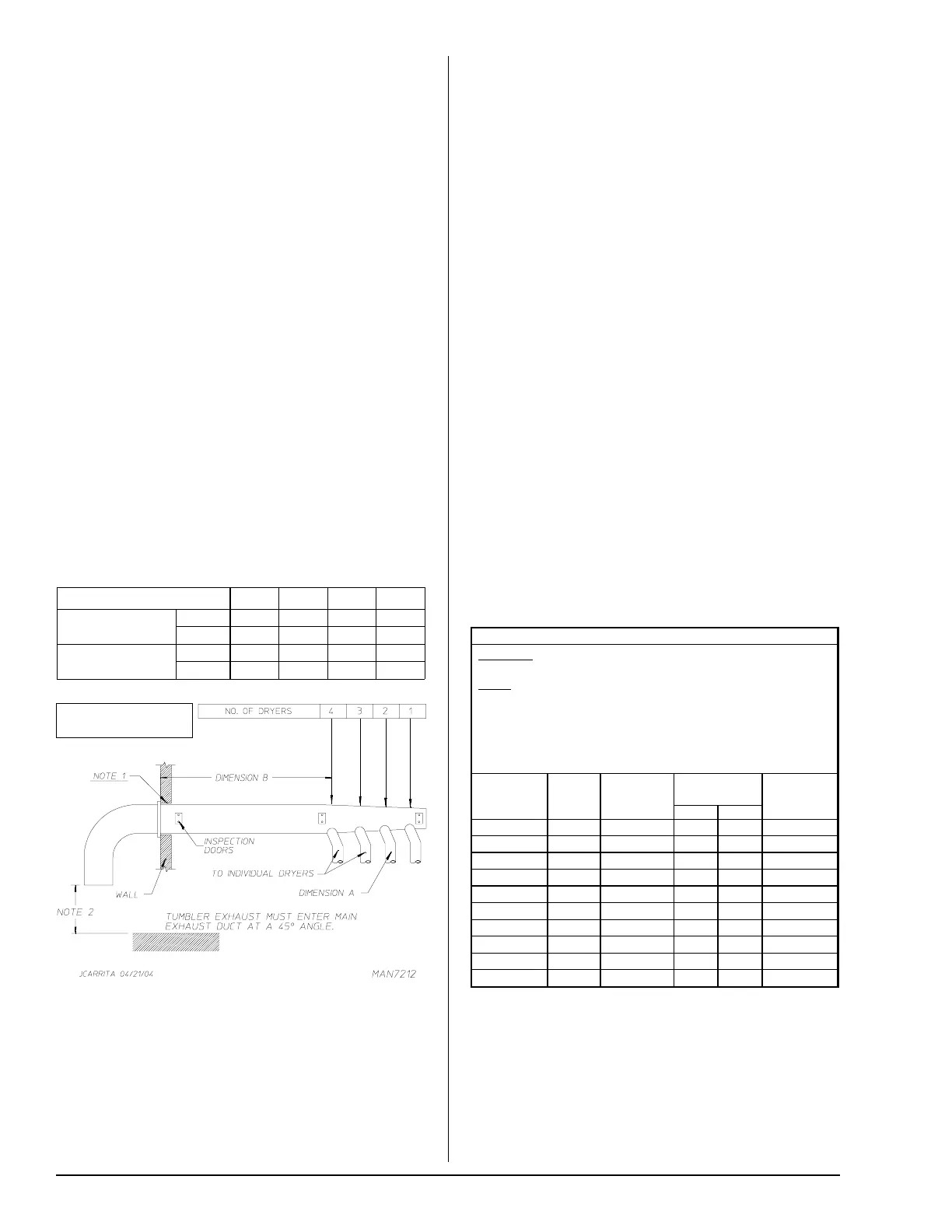

NUMBER OF DRYERS 4 3 2 1

MINIMUM CROSS-

SECTIONAL AREA

SQ IN 615 455 315 200

SQ CM 3967 2935 2032 1290

MINIMUM ROUND

DUCT DIAMETER

IN 28 24 20 16

CM 71 61 50 40

Electrical Information _______________

Electrical Requirements

It is your responsibility to have all electrical connections

made by a properly licensed and competent electrician to

assure that the electrical installation is adequate and

conforms to local and state regulations or codes. In the

absence of such codes, all electrical connections, material,

and workmanship must conform to the applicable

requirements of the National Electrical Code ANSI/NFPA

NO. 70-LATEST EDITION or in Canada, the Canadian

Installation Codes CAN/CGA-B149.1-M91 (Natural Gas) or

CAN/CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION.

IMPORTANT: Failure to comply with these codes or

ordinances, and/or the requirements stipulated in this

manual can result in personal injury or component failure.

NOTE:

Component failure due to improper installation will

void the warranty.

Each dryer should be connected to an independently

protected branch circuit. The dryer must be connected with

copper wire only. Do not use aluminum wire, which could

cause a fire hazard. The copper conductor wire/cable must

be of proper ampacity and insulation in accordance with

electric codes for making all service connections.

NOTE:

The use of aluminum wire will void the warranty.

Wiring diagrams are affixed to the inside at the top front

control door and the rear upper back guard/panel.

Electrical Service Specifications

Gas and Steam Models Only

NOTE 1 Opening must be 2-inches (5.08 cm) larger than the duct (all the

way around). The duct must be centered within this opening.

NOTE 2 Distance should be 2 times the diameter of the duct to the nearest

obstruction.

NOTE:

When the exhaust ductwork passes through a

wall, ceiling, or roof made of combustible materials, the

opening must be 2-inches (5.08 cm) larger than the duct

(all the way around). The duct must be centered within

this duct.

IMPORTANT: For extended ductwork runs, the cross

section area of the ductwork can only be increased to an

extent. Maximum proportional ductwork runs cannot

exceed 20 feet (6.09 meters) more than the original

limitations of 20 feet (6.09 meters) with two elbows.

When the ductwork approaches the maximum limits as

noted in this manual, a professional HVAC firm should be

consulted for proper venting information.

Exhaust back pressure measured by a manometer/

magnehelic in the exhaust duct must be no less than 0

and must not exceed 0.3 in WC (0.74 mb).

NOTE: It is recommended that exhaust or booster fans

not be used in the exhaust ductwork system except where

necessary to maintain exhaust back pressure (in the

exhaust duct) between zero and 0.3 inch water column.

Where employed, booster fans must not activate the dryer

airflow proving switch (sail switch) when the dryer is not in

operation.

The ductwork should be smooth inside with no projections

from sheet metal screws or other obstructions, which will

collect lint. When adding ducts, the duct to be added should

overlap the duct to which it is to be connected. All ductwork

joints must be taped to prevent moisture and lint from

escaping into the building. Inspection doors should be

installed at strategic points in the exhaust ductwork for

periodic inspection and cleaning of lint from the ductwork.

Multiple Dryer Venting 16-Inch (40.64 cm)

Diameter Minimum Exhaust Connections at Common Duct

A = 48-3/4” (123.82 cm)

B = 20 feet (6.09 meters)

* 3-Wire is available. 3/26/15

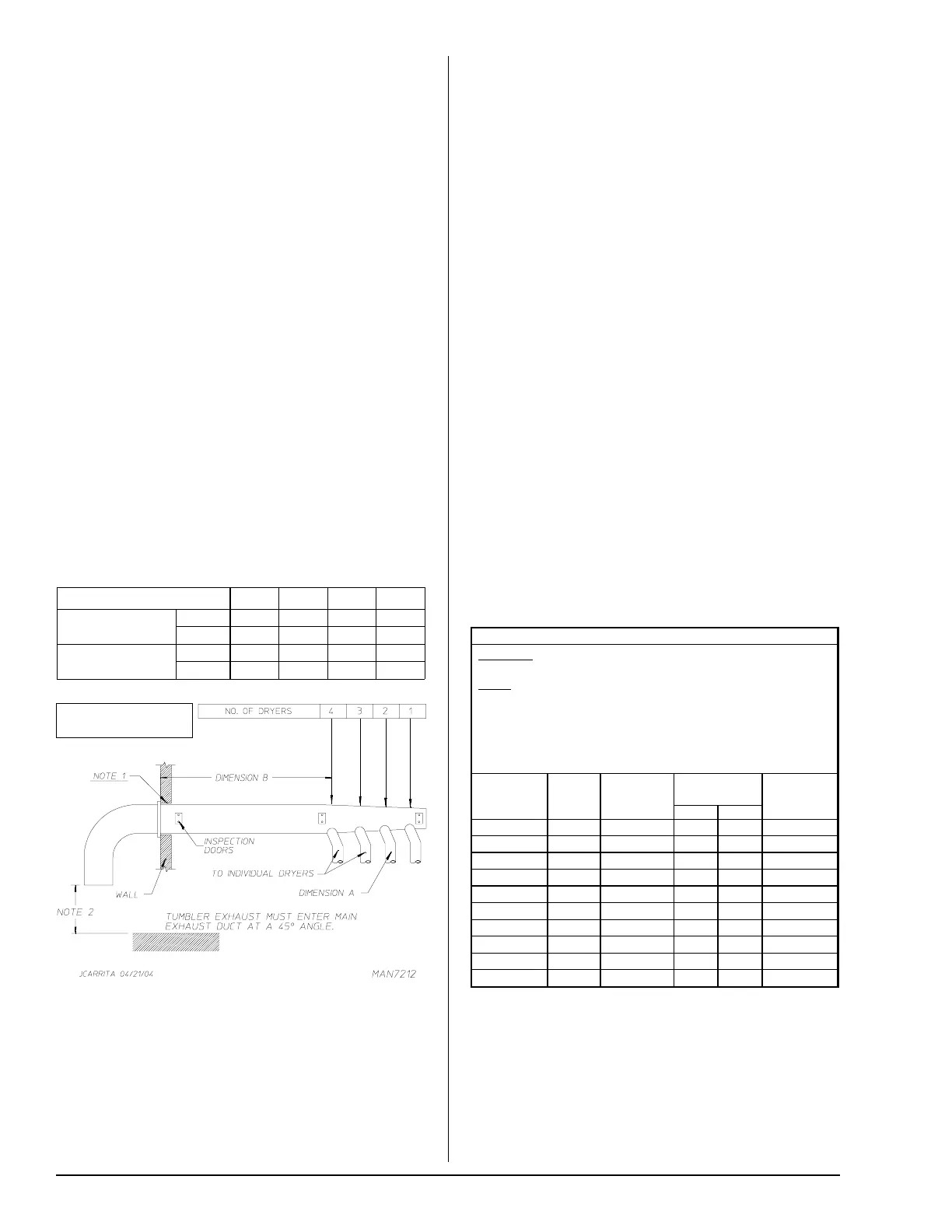

ELECTRICAL SERVICE SPECIFICATIONS (PER DRYER)

IMPORTANT:

NOTES

: A.

B.

C.

208 VAC AND 230/240 VAC ARE NOT THE SAME. When ordering,

specify exact voltage.

When fuses are used they must be dual element, time delay, current

limiting, class RK1 or RK5 ONLY. Calculate/determine correct fuse

value, by applying either local and/or National Electrical Codes to

listed appliance amp draw data.

Circuit breakers are thermal-magnetic (industrial) motor curve type

ONLY. For others, calculate/verify correct breaker size according to

appliance amp draw rating and type of breaker used.

Circuit breakers for 3-phase (3ø) dryers must be 3-pole type.

SERVICE

VOLTAGE

PHASE

WIRE

SERVICE

APPROX.

AMP DRAW

CIRCUIT

BREAKER

60 Hz 50 Hz

208 3ø 3 14 — 20

220 3ø 3 — 11 15

230 3ø 3 13 — 15

240 3ø 3 12 11 15

380 3ø 4* —6 15

400 3ø 4* —6 15

416 3ø 4* —6 15

440 3ø 3 7 — 15

460 3ø 3 7 — 15

480 3ø 3 7 — 15

Loading...

Loading...