113375-16 Telephone 01422 822282 21

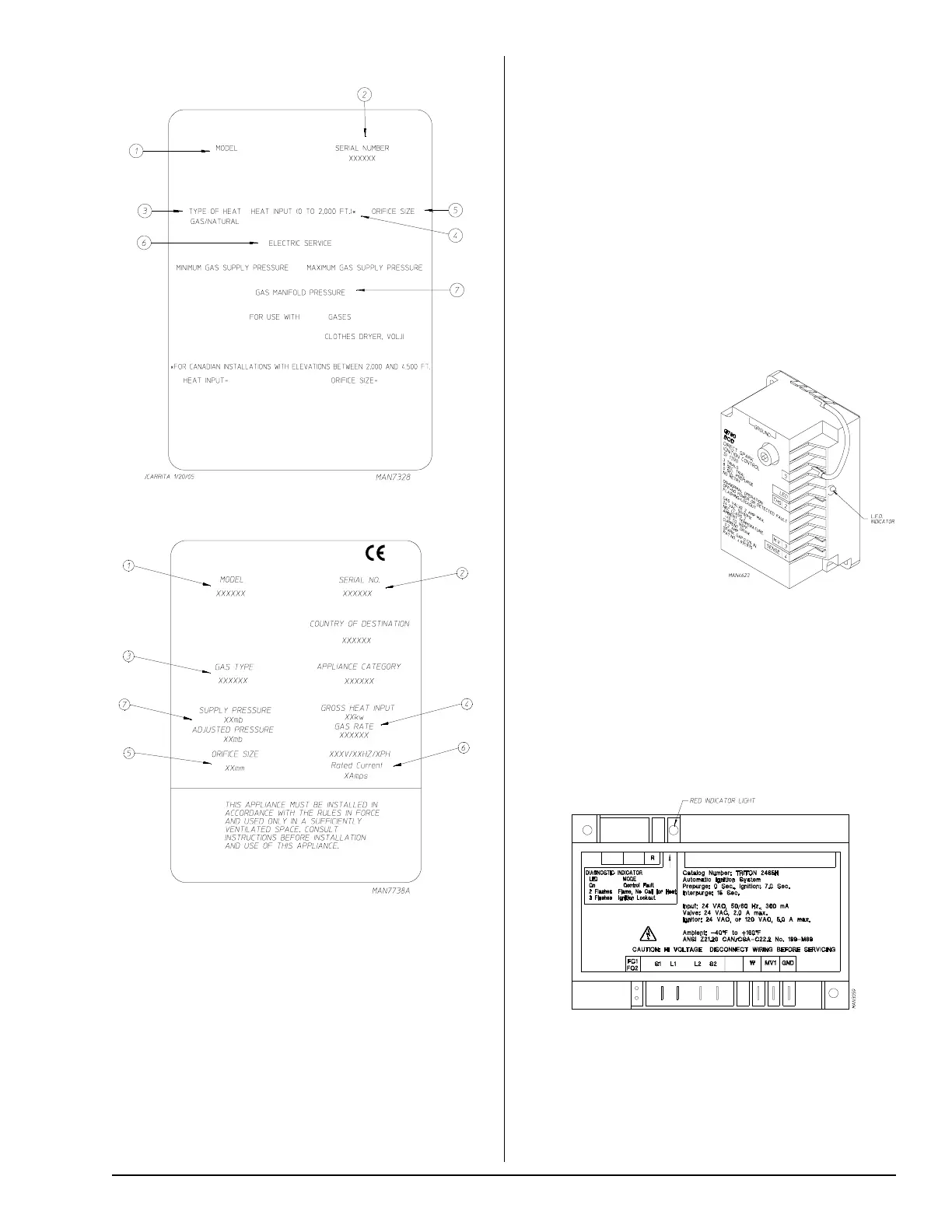

Data Label Information ______________

Standard Label

Procedure for Functional Check

of Replacement Components ________

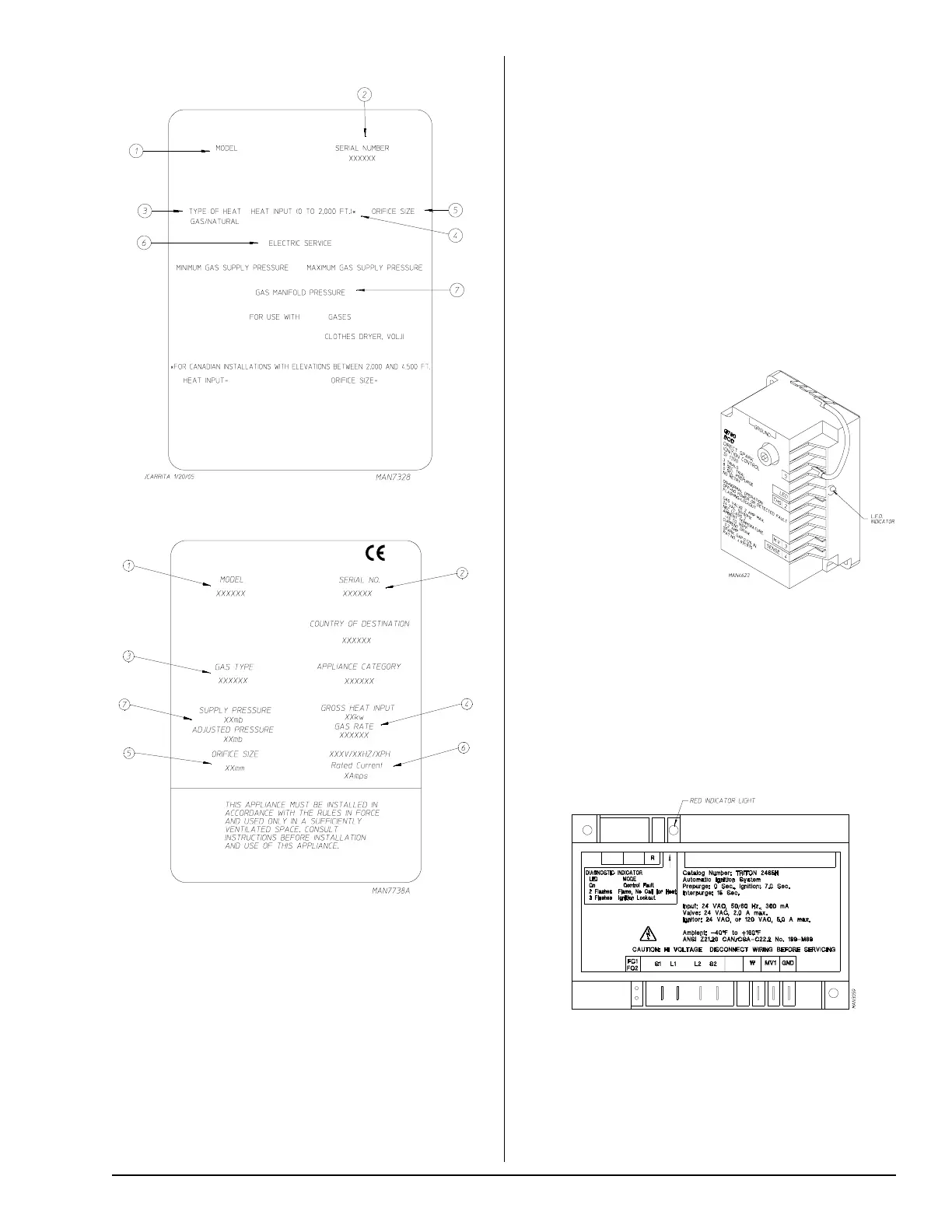

For Heat Control Module Ignition Circuit

For Models with Johnson Controls

DSI Module (G760)

Theory Of Operation

Start the drying cycle. When

the gas burner ignites within

the chosen trial for ignition

time (6-seconds), the flame

sensor detects gas burner

flame and signals the DSI

module to keep the gas valve

open … as long as there is a

call for heat. The DSI

module will “LOCKOUT” if

the gas burner flame is not

sensed at the end of the trial

for ignition period. The trial for ignition period will be repeated

for a total of three retries/trials (the initial try and two more

retries/trials). If the flame is not sensed at the end of the

third retry/trial (inter-purge period of 30-seconds) the DSI

module will “LOCKOUT” (L.E.D. flashes).

A steady L.E.D. indicator indicates normal operation.

No L.E.D. indicator indicates a power or an internal failure

has occurred.

For Models with HSI Module

Start the drying cycle.

The HSI will turn on, and after approximately 4-seconds the

ignitor will shut off and the gas valve will be energized.

Ignition (flame) should now be established.

With the burner flame on, remove the flame sensor wire

from the S2 terminal of the HSI module. The burner flame

must shut off immediately.

CE Label

4. Heat Input (For Gas Dryers) – This describes the heat

input in British thermal units per hour (Btu/hr) or kilowatts

(kW).

5. Orifice Size (For Gas Dryers) – Gives the number drill

size used.

6. Electric Service – This describes the voltage and

current rating for a particular model.

7. Gas Manifold Pressure (For Gas Dryers) – This

describes the manifold pressure taken at the gas valve

tap.

When contacting JLA, certain information is required to

ensure proper service/parts information from JLA. This

information is on the data label that is affixed to the rear

upper left back area of the dryer, which can be viewed either

through the openings in the dryer’s back panel/guard, or by

removing this back panel/guard. When contacting JLA,

please have the model number and serial number available.

1. Model Number – This describes the style of dryer and

type of heat (gas, electric, or steam).

2. Serial Number – Allows the manufacturer to gather

information on your particular dryer.

3. Type of Heat – This describes the type of heat for

your particular dryer, gas (either natural gas or L.P. gas),

electric, or steam.

Loading...

Loading...