iii Installation procedures

Refer to the drawing in i for correct wheel balancer

positioning. If the wheel balancer needs securing,

we recommend xing elements with a diameter of

8 mm, quality 8.8 or higher.

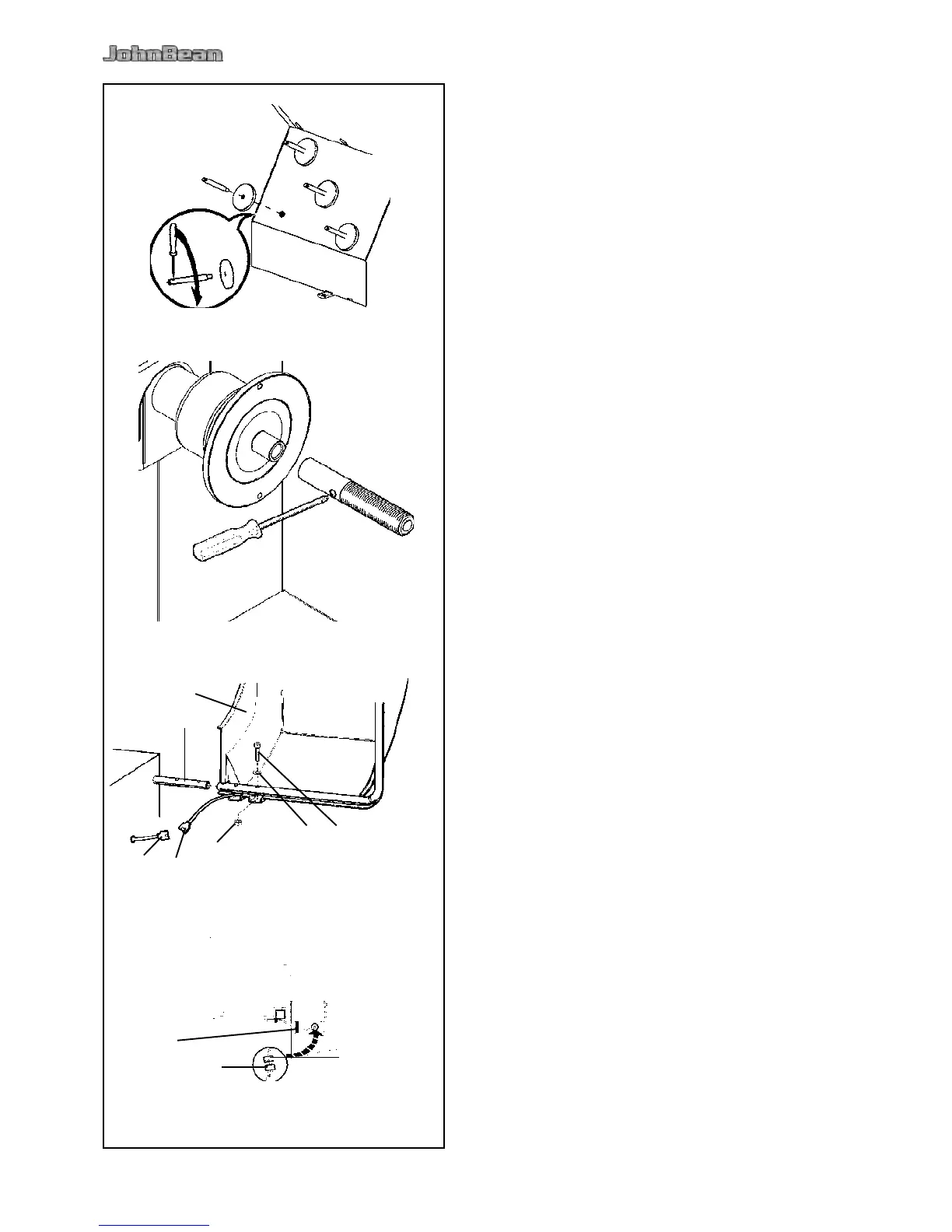

• Unpack the 4 threaded accessory support studs

and the support plates.

• Refer to Figure iii-1. Fit the 4 threaded accessory

support studs and the plates.

• Clean the stub shaft and the hole in the main shaft.

• Refer to Figure iii-2. Position the stub shaft.

• Use a pin for screwing.

• Put the clamping devices on the accessory studs.

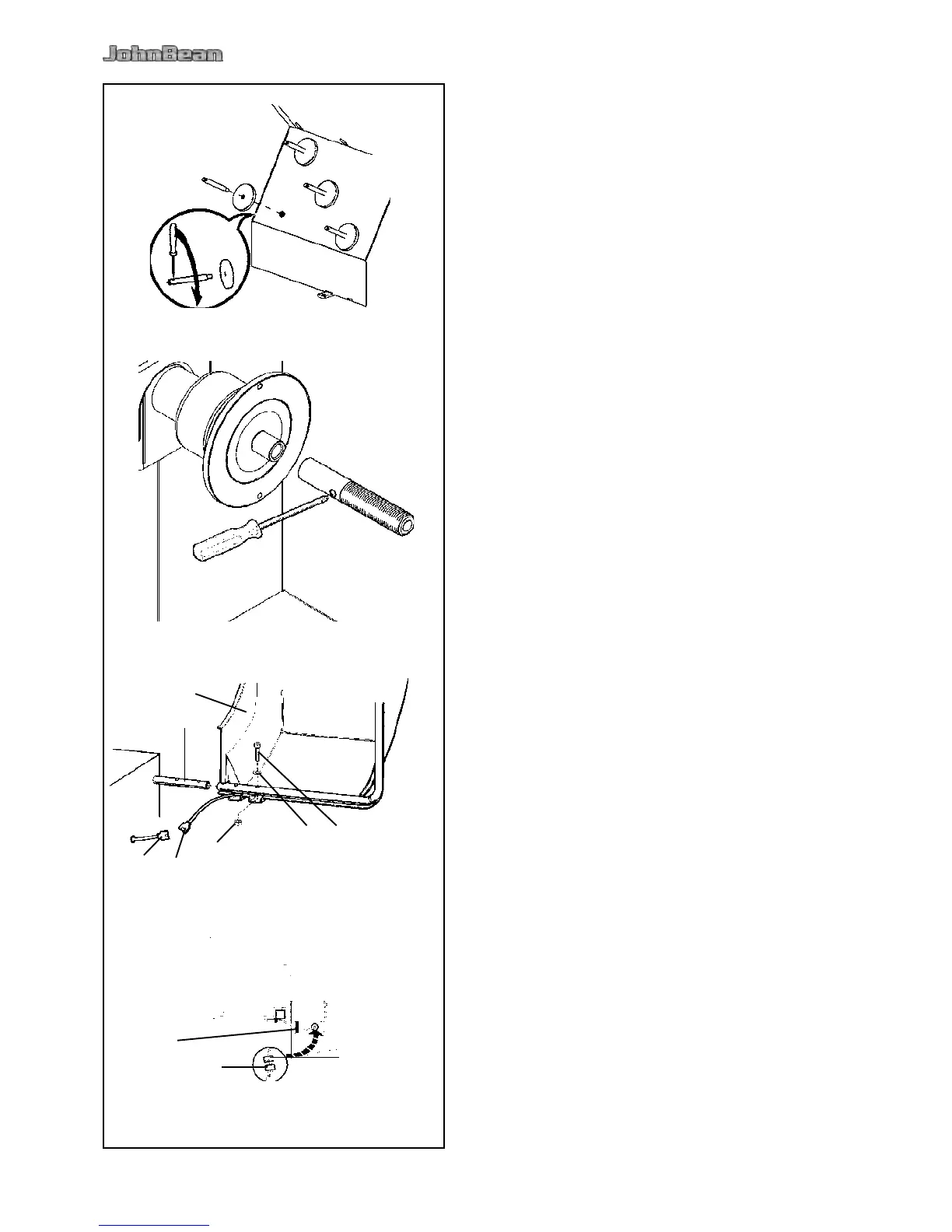

• Refer to Figure iii-3.

The measuring run is started by closing the wheel

guard (code C 13).

The wheel is braked on lifting the wheel guard

during a measuring run (code C 5).

Fig. iii-3

Slide the wheel guard (1) on the arbor (2) and raise

it until the fastening holes of wheel guard and wheel

guard arbor coincide.

Insert the M10 setscrew (3) with washer (4) from

below, and tighten the hexagon nut (5) and washer.

Connect the plug of the cable (6) with the connector

of the machine (7) which is projecting out of the

opening in the machine cabinet.

Place the plugs loosely inside the machine through

the hole in the machine cabinet.

Caution:

Since the cable is moved during opening and closing

the wheel guard, it must be passed in the band (8, Fig.

iii-3a) under the wheel guard.

Loading...

Loading...