Do you have a question about the Johnson Controls CGM04060 and is the answer not in the manual?

Describes the CGM controllers and their capabilities in monitoring and controlling HVAC equipment.

Details how CGM controllers communicate using BACnet MS/TP, N2, or wireless Zigbee protocols.

Covers FCC and Canadian regulations for digital devices, ensuring reasonable protection against interference.

Provides general guidelines for handling, transporting, and installing the controller safely.

Lists the items shipped with the controller and the tools/materials needed for installation.

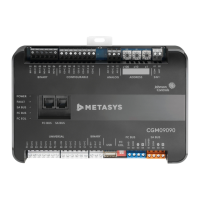

Details the physical layout, components, and terminal blocks of the CGM controllers.

Provides instructions for secure and proper controller mounting on various surfaces.

Instructions for mounting the controller horizontally on a 35 mm DIN rail.

Instructions for mounting the controller directly on a wall or flat vertical surface.

General guidelines and cautions to observe when wiring a CGM controller.

Describes the removable input and output terminal blocks on the controller.

Explains the FC bus terminal block, its function, and wiring.

Details the SA Bus port, its connection to the terminal block, and supported devices.

Describes the 24 VAC supply power terminal block and wiring requirements.

Provides further guidelines on input/output wiring, cable length, and supply power.

Explains universal input terminal functions, ratings, and cable guidelines.

Details functions, ratings, and cable guidelines for configurable output terminals.

Explains functions, ratings, and cable guidelines for analog output terminals.

Illustrates maximum cable length relative to wire size and load current for low-voltage inputs/outputs.

Details terminal block functions, ratings, and recommended cable types for FC and SA buses.

Shows termination diagrams for wiring a temperature sensor to the controller.

Details the termination diagram for connecting EPP-1000 feedback to the controller.

Illustrates termination diagrams for wiring dry contact (binary) inputs.

Shows termination diagrams for wiring 0-10 VDC analog outputs.

Details termination diagrams for analog output connections.

Shows termination diagrams for 4-20 mA output connections.

Details termination diagrams for 24 VAC binary output connections.

Shows termination diagrams for incremental control output connections.

Steps to configure the controller to communicate using the N2 protocol.

Steps to configure a controller for use with the ZFR Pro Series Wireless Field Bus system.

How to set unique and sequential device addresses for bus applications.

Instructions for detaching terminal blocks from the circuit board.

How to set the End-of-Line (EOL) switch for bus termination.

Information on connecting and setting up a DIS1710 Local Controller Display.

How to validate controller input/output wiring before application download.

Guidance for diagnosing and resolving controller issues based on status LEDs.

Explains the meaning of controller status LEDs for troubleshooting.

Details product codes and descriptions for CGM controllers.

Information on kits for replacing terminal blocks and diagnostic tools.

Details power requirement, consumption, I/O capabilities, and accuracy.

Information on product weight, regulatory compliance, and certifications.

Details on the product's limited warranty and how to obtain support.

| Manufacturer | Johnson Controls |

|---|---|

| Model Number | CGM04060 |

| Communication Protocol | BACnet MS/TP |

| Power Supply | 24 VAC |

| Enclosure Rating | IP20 |

| Application | HVAC Control |

| Inputs | 4 Universal Inputs |

| Operating Temperature | -40°C to 70°C |

| Outputs | 6 Configurable Outputs |

Loading...

Loading...