Do you have a question about the Johnson Controls CGM09090 and is the answer not in the manual?

Describes communication methods: BACnet MS/TP, N2, and wireless Zigbee.

Details FCC and Canadian compliance requirements for digital devices.

Provides essential guidelines for installing a CGM Controller, including parts and tools.

Offers guidelines for mounting the controller securely on DIN rail or a wall surface.

Explains the procedure for mounting the controller horizontally on a 35 mm DIN rail.

Details the steps for mounting the controller directly on a wall or flat vertical surface.

Presents guidelines for wiring the CGM controller, emphasizing safety precautions.

Describes removable terminal blocks for input/output functions, located at top and bottom.

Details the blue, removable FC bus terminal block and its primary function.

Describes the orange, removable SA bus terminal block and its wiring configuration.

Explains the RJ-12 SA Bus port for connecting various devices like MAP Gateway or sensors.

Details the gray, 2-pin terminal block for 24 VAC supply power connection.

Provides guidelines for wiring, cable lengths, and power connections for buses.

Details functions, ratings, and cable guidelines for Universal Input terminals (UI-n).

Outlines functions, ratings, and cable guidelines for Binary Input terminals (BI-n).

Explains functions, ratings, and cable guidelines for Configurable Output terminals (CO-n).

Details functions, ratings, and cable guidelines for Analog Output terminals (AO-n).

Describes functions, ratings, and cable guidelines for Binary Output terminals (BO-n).

Illustrates maximum cable length based on wire size and load current for inputs/outputs.

Provides guidelines for FC Bus, SA Bus, and 24 VAC supply power wiring.

Shows diagrams for wiring various input/output devices like sensors and actuators.

Details the termination diagram for current input from an isolated external source.

Shows the termination diagram for feedback signals from an EPP-1000 device.

Provides the termination diagram for dry contact binary inputs.

Illustrates termination diagrams for 0-10 VDC output to actuators.

Shows termination diagrams for 24 VAC Triac outputs.

Details termination diagrams for analog current outputs.

Provides termination diagrams for 4-20 mA output to actuators.

Shows termination diagrams for incremental control outputs.

Illustrates termination diagrams for 24 VAC binary outputs.

Details termination diagrams for incremental control outputs.

Explains wiring for network stats with addressable or fixed addresses using SA Bus.

Steps to configure the controller for the N2 communication protocol.

Explains setting unique device addresses using rotary switches for bus applications.

Steps to configure a controller for use with the ZFR Pro Series Wireless Field Bus.

Explains how to set unique device addresses using rotary switches.

Instructions for safely removing the controller's housing cover.

Details how to set the EOL switch for proper bus termination.

Discusses connecting to a DIS1710 Local Controller Display for setup.

Explains validating wiring using the default state and Fault LED.

Guides on interpreting LED status indicators for troubleshooting controller issues.

Lists product codes and descriptions for CGM models and accessories.

Describes the Field Inspection Tool (FIT) for testing and troubleshooting buses.

Details the power requirements for the controller, including VAC and frequency.

Specifies operating and storage ambient conditions for the controller.

Lists the types of Universal Inputs and Outputs the controller supports.

Lists compliance certifications for the controller in various regions.

Provides contact details for local branches and Johnson Controls support.

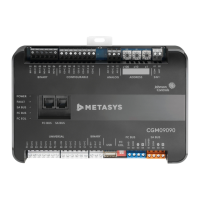

| Brand | Johnson Controls |

|---|---|

| Model | CGM09090 |

| Category | Controller |

| Language | English |

Loading...

Loading...