Note: Do not use the modular SA Bus port and the

terminal block SA Bus simultaneously. Only use one

of these connections at a time.

Note: The CGM controller is the EOL for the SA Bus.

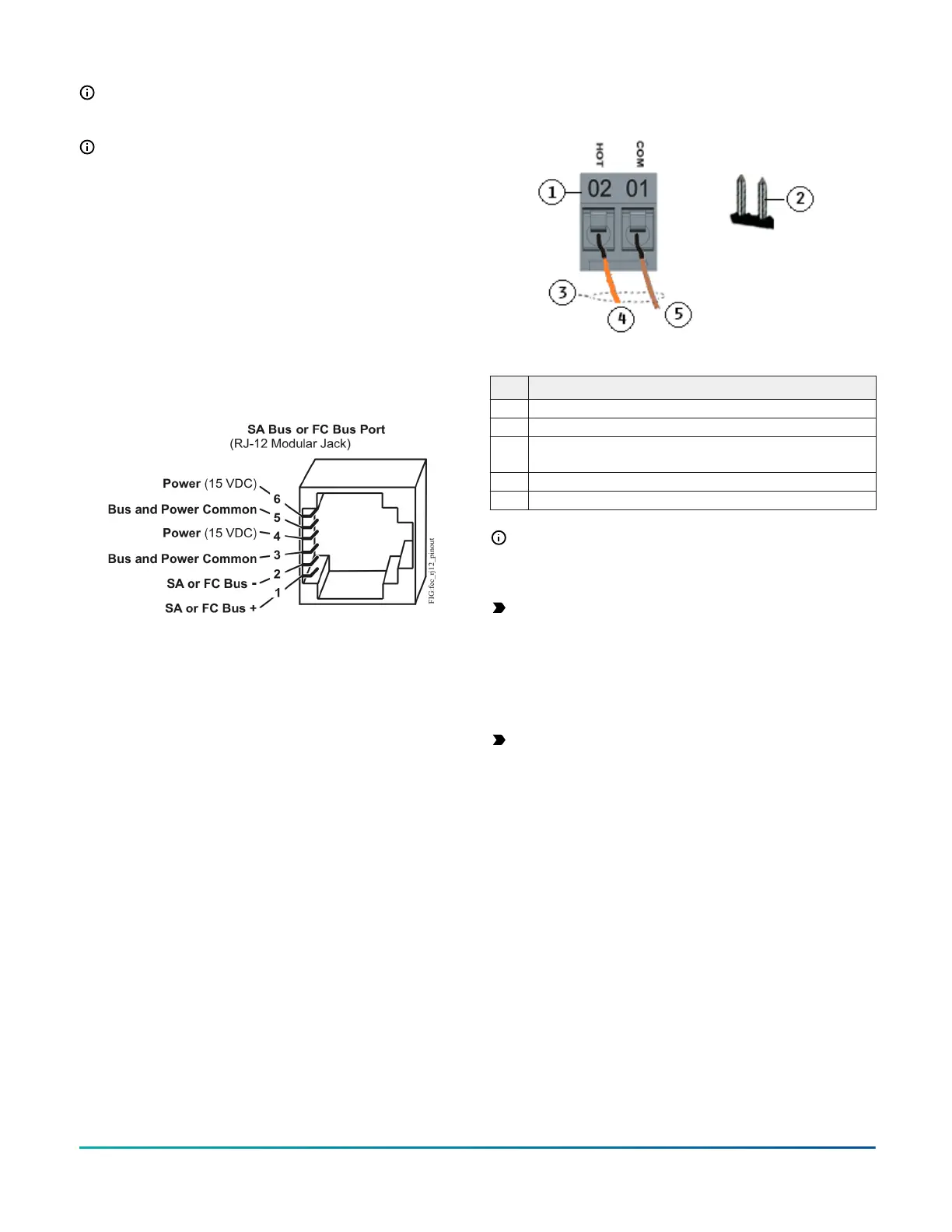

FC bus port

The FC bus port on the front of the controller is an RJ-12,

6-position modular jack that provides a connection for the

Mobile Access Portal (MAP) Gateway, or the ZFR/ZFR Pro

Wireless Field Bus Router.

The FC bus port is connected internally to the FC bus

terminal block. See Table 5 for more information

about communication bus port functions, ratings, and

requirements. The FC bus port pin assignment is shown in

Figure 7.

Figure 7: Pin number assignments for FC bus and SA

bus ports on equipment controllers

SA Bus port

The SA Bus port on the front of the controller is an RJ-12,

6-position modular jack that provides a connection for the

MAP Gateway, the VAV Balancing Tool, the DIS1710 local

controller display, specified network sensors, or other SA

Bus devices with RJ-12 plugs. When the CGM is configured

for N2 network communication, you must download and

commission the controller using the SA Bus port.

The Sensor port is connected internally to the SA

bus terminal block. See Table 5 for more information

about communication bus port functions, ratings, and

requirements. The SA Bus port pin assignment is shown in

Figure 7.

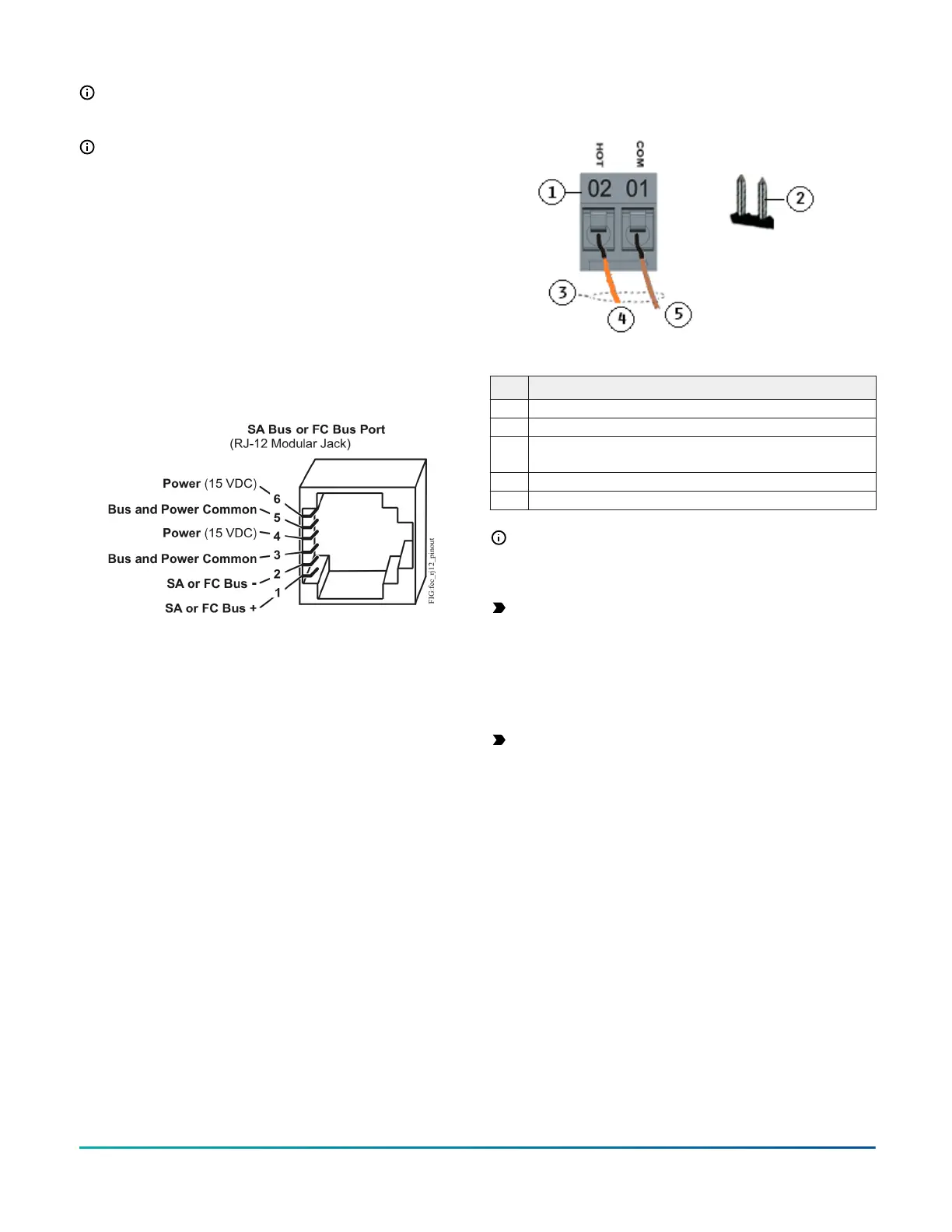

Supply power terminal block

The 24 VAC supply power terminal block is a gray,

removable, 2-pin terminal block that fits into a board-

mounted pin header on the top right of the controller.

Wire the 24 VAC supply power wires from the transformer

to the HOT and COM terminals on the terminal plug as

shown in Figure 8. For more information about the Supply

Power Terminal Block, see Table 5.

Figure 8: 24 VAC supply power terminal block wiring

Table 2: Supply power terminal block wiring

Description

1 Supply power terminal block

2 Supply power terminal header

3

Wires from Johnson Controls 24 VAC, class 2 power

transformer

4 24 VAC (Orange wire)

5 COM (Brown wire)

Note: The supply power wire colors may be different

on transformers from other manufacturers. Refer to

the transformer manufacturer’s instructions and the

project installation drawings for wiring details.

Important: Connect 24 VAC supply power to the

equipment controller and all other network devices

so that transformer phasing is uniform across the

network devices. Powering network devices with

uniform 24 VAC supply power phasing reduces

noise, interference, and ground loop problems. The

equipment controller does not require an earth

ground connection.

Important: Power wires must be less than 30 meters

(100 ft) between controller and transformer

Terminal wiring guidelines, functions,

ratings, and requirements

This section provides further guidelines on input and

output wiring, maximum cable length versus load current,

and SA Bus and supply power wiring.

For information about removing a terminal block from the

controller, see Removing a terminal block.

Input and Output wiring guidelines

Table 3 provides information and guidelines about the

functions, ratings, and requirements for the controller

input and output terminals, and Table 4 also references

guidelines for determining proper wire sizes and cable

lengths.

In addition to the wiring guidelines in Table 3, observe

these guidelines when wiring controller inputs and

outputs:

• Run all low-voltage wiring and cables separate from

high-voltage wiring.

M4-CGM General Purpose Application Controller Installation Guide 5

Loading...

Loading...