Do you have a question about the Johnson Controls M4-CGM09090 and is the answer not in the manual?

Compliance with FCC rules for commercial environments.

FCC compliance for Class A digital devices.

Canadian interference-causing equipment regulations.

General guidelines for safe installation and handling.

Surface support, orientation, and environmental factors.

Recommended techniques for different mounting types.

Install rail and extend mounting clips.

Disconnect power, check wiring, use copper.

Rules for wiring terminals and ports.

Importance of consistent power phasing.

Information on wiring, load current, and cable lengths.

Table of terminal functions, ratings, and cables.

Functions and requirements for Universal Inputs.

Functions and requirements for Binary Inputs.

Functions and requirements for Configurable Outputs.

Functions and requirements for Analog Outputs.

Functions and requirements for Binary Outputs.

Table defining cable length guidelines.

Specific cable length and wire size data.

Graphical tool for cable length estimation.

Information on bus and power terminals.

Comprehensive specifications.

Introduction to wiring diagrams.

Procedure for protocol conversion.

Steps for wireless setup.

Matching addresses with software.

Importance and process of setting unique addresses.

Valid address ranges for different modes.

Purpose and physical location of the switch.

Using CCT for controller setup.

Interpreting LED indicators.

Comprehensive guide to LED behavior.

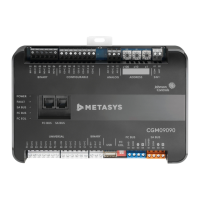

Detailed specs for the controller.

List of certifications and standards.

| Enclosure Rating | IP20 |

|---|---|

| Supply Voltage | 24 VAC |

| Operating Temperature | -40 to 70 °C |

| Humidity Range | 10% to 90% non-condensing |

| Communication Protocol | BACnet MS/TP |

Loading...

Loading...