3. If the controller is a terminating device on the FC

bus, set the EOL switch to ON. If the controller is

not a terminating device on the bus, set the EOL

switch to Off.

When a controller is connected to power with its

EOL switch set to ON, the amber EOL LED on the

controller cover is illuminated.

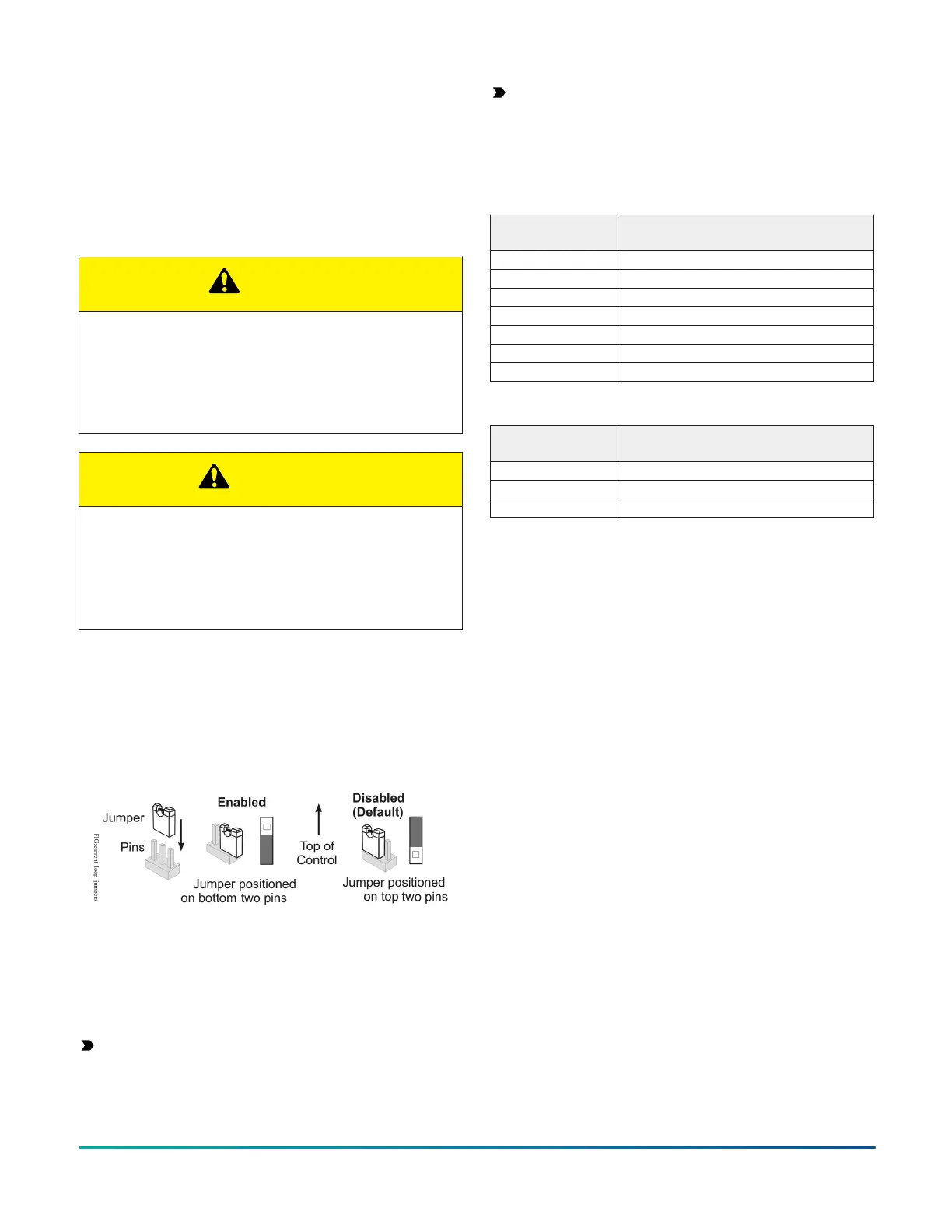

Setting the UI current loop jumpers

CAUTION

Risk of Electric Shock:

Disconnect supply power to the devices before

attempting to adjust the UI current loop jumpers.

Failure to disconnect the supply power may result in

electric shock.

ATTENTION

Mise En Garde: Risque de décharge électrique:

Débrancher l'alimentation de l'controller avant tout

réglage du UI current loop jumpers. Le non-respect de

cette précaution risque de provoquer une décharge

électrique.

The UI current loop jumpers are on the circuit board

under the controller cover near the UI terminals (Figure

12). When a UI is defined (in the system software) as a

4-20 mA Analog Input, set the UI's current loop jumper to

the Enabled position (Figure 14).

Figure 14: UI Current Loop Jumper Positions

Setting the current loop jumper to the Enabled position,

connects an internal 100 ohm resistor across the UI

terminals, which maintains the 4-20 mA current loop

circuit even when power to the controller is interrupted or

off.

Important: Current Loop jumpers must be in the

Disabled (default) position for all UIs that are not set

up to operate as 4-20 mA analog inputs.

Important: A current loop jumper must be in the

Enabled position to maintain a closed 4-20 mA

current loop.

The following tables identify the current loop switches

associated with each UI on the CGM09090 and CGM04060

controllers.

Table 8: CGM09090 UI Inputs and jumper labels

Universal Input

label

Jumper label on circuit board

UI-1 J13

UI-2 J14

UI-3 J15

UI-4 J16

UI-5 J17

UI-6 J18

UI-7 J19

Table 9: CGM04060 UI Inputs and jumper labels

Universal Input

label

Jumper label on circuit board

UI-1 J10

UI-2 J11

UI-3 J12

Setting up a local display

CGM models do not have an integral display, but can

be connected to a DIS1710 Local Controller Display. For

detailed information about setting up and operating a

remotely connected DIS1710 display, refer to the DIS1710

Local Controller Display Technical Bulletin (LIT-12011270).

Input/Output Wiring Validation

The CGM controllers ship with a default state that can

assist in validating the wiring of the input and output

terminals prior to download of an application file. When

the controller is powered on in this state, the Fault LED

will flash in a pattern of two quick blinks and then a long

pause (see Table 10).

To make use of this feature, ensure the rotary switches

are set to the desired address and wire the input and

output terminals. Apply power to the CGM controller

and connect to the device with either a MAP Gateway

or MS-DIS1710-0 Local Display to view the points in the

controller. The CGM controller will report an Operational

status even though there is no true application loaded.

CCT will not be able to commission or upload the device

as a result until a true application is downloaded. The

application name displayed will be the address of the

controller followed by the model of the controller and

“Default State”.

For example, a CGM09090 controller whose rotary

switches are set to 8 would have the default state

application name of “8-CGM09090 Default State”.

The default state creates I/O points for all connections

on the input and output terminals. It assumes all

Universal Inputs (UIs) are Nickel temperature sensors. All

Configurable Outputs (COs) are treated as Binary Outputs

(BOs) with an initial value of 0. The default state also takes

input from a Network Sensor at address 199. If there is

M4-CGM General Purpose Application Controller Installation Guide18

Loading...

Loading...