XL EVAPORATIVE COOLING PRODUCTS

MAINTENANCE

S140-600 IOM (NOV 07)

Page 13

pan water level should be even with the centerline of the

overfl ow when the unit is not running. This will prevent the

pump from cavitating when the spray system is in operation.

The water level is easily adjusted by loosening the wing nut

on the valve and raising or lowering the ball to maintain the

proper level. The recommended operating pressure for the

water makeup valve is 15 to 20 PSI.

MOISTURE ELIMINATORS

The moisture eliminators are located on top of the unit and

prevent losses of the spray water due to water being entrained

in the air stream as it passes through the unit. The eliminators

should be checked monthly to remove any obstructions that

may be trapped between the blades and to ensure proper

positioning.

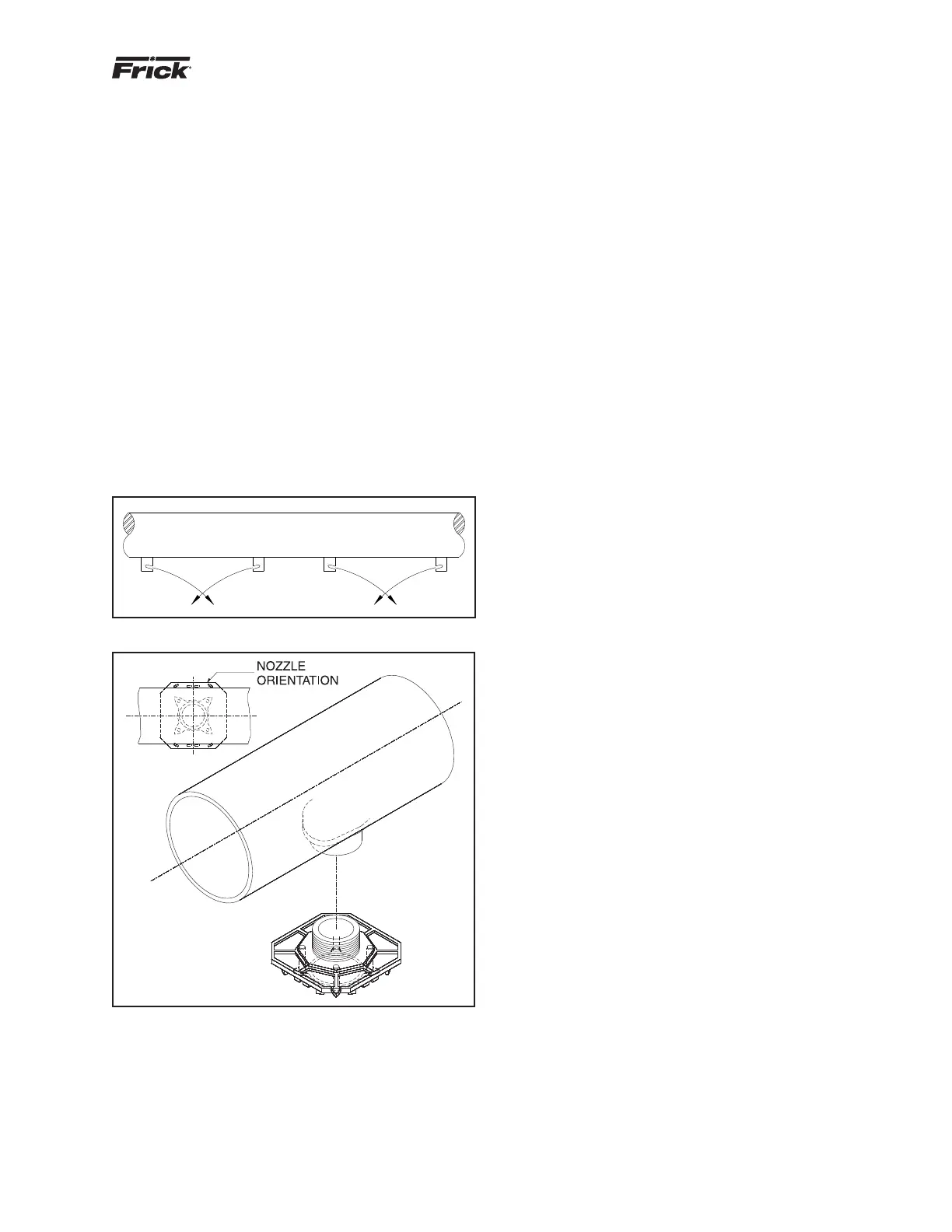

WATER DISTRIBUTION SYSTEM

The spray nozzles are accessible by moving the eliminators

in sections from the top of the unit (DO NOT OPERATE UNIT

WITHOUT ELIMINATORS). The spray nozzles are large

orifi ce, cleanable type. For XLC units, the nozzles should be

checked monthly to see that the spray pattern is complete

and even. Figure 12 shows the nozzle orientation in the spray

headers and the spray direction.

Figure 12 - XLC Spray Header Nozzle Orientation

Figure 13 - XLP Spray Header Nozzle Orientation

XLP units include low pressure, large orifi ce, clog-resistant

nozzles. They features a large 2" connection that provides

consistent, highly uniform water fl ow over a 6' square area

of the coil bundle for maximum heat transfer.

The large nozzle opening avoids the pitfalls of most other

nozzles because most materials will pass straight through,

avoiding much of the maintenance required by smaller,

competitive nozzles. There is adequate space below the

nozzle and a wide opening to allow large debris to be pulled

out. Furthermore, with the fi xed design, this nozzle is much

more tolerant of harsh water conditions that lead to wear on

moving nozzles

NOTE: If the nozzle is removed for cleaning, always

ensure that the initial orientation of the nozzle is main-

tained. See Figure 13.

HEAT TRANSFER SECTION

The coil should be examined monthly for signs of scale

buildup, and any obstructions between the tubes should be

removed. If there is evidence of scale buildup on the coil,

check the bleed valve for adequate bleed-off. If the bleed-off

valve is functioning properly, contact your local water treat-

ment company for recommendations.

FAN MOTOR AND SPRAY PUMP MOTOR

The motors should be checked and/or lubricated every six

months according to the motor manufacturers recommen-

dations.

FAN BEARINGS

The fan bearings should be checked monthly and relubri-

cated. The bearings should be lubricated while in operation,

and the grease should be pumped in slowly until a slight

bead forms around the seals. The grease will increase in

temperature approximately 30°F during the relubrication. If

the relubrication must be done while the bearings are not

in operation, the grease capacity of each bearing on the

XLC units is 7/8 ounce. The capacity on the XLP units is

3/8 ounce. The grease should conform to NLGI Grade Two

consistency and should be free of any chemical impurities

such as free acid or free alkali, dust, rust, metal particles

or abrasives. Bearings should be lubricated with hand

grease guns only.

The following types of grease meet the above criteria:

MOBILITH 22

MOBILUX #2

SHELL ALVANIA #2

UNIREX N2

TEXACO MULTIFAX #2

TEXACO PREMIUM RB

FAN DRIVE AND BELTS

The fan and motor sheaves and belt tension should be

checked every month using the procedure outlined below.

The sheaves should be tight on the shafts and should be

aligned properly to minimize belt wear. The belts should

be checked for wear along the edges as any irregularity

will cause vibration. If the belts are not wearing evenly, the

cause could be improper sheave alignment. Use the sheave

alignment procedure below to check the sheave alignment.

If any belt requires replacement, replace all the belts with a

matched set, never one at a time.

SHEAVE INSPECTION

Check the sheaves for proper alignment, excessive corro-

sion, and wear or damage. Also, check the belt for excessive

heat. If the belt is too hot to touch, then the sheaves may be

damaged or need aligning.

If the sheaves have excessive corrosion or are worn or dam-

aged, they should be replaced. Check for sharp edges from

wear or pitting of the grooves from corrosion. Either condition

Loading...

Loading...