XL EVAPORATIVE COOLING PRODUCTS

INSTALLATION

S140-600 IOM (NOV 07)

Page 5

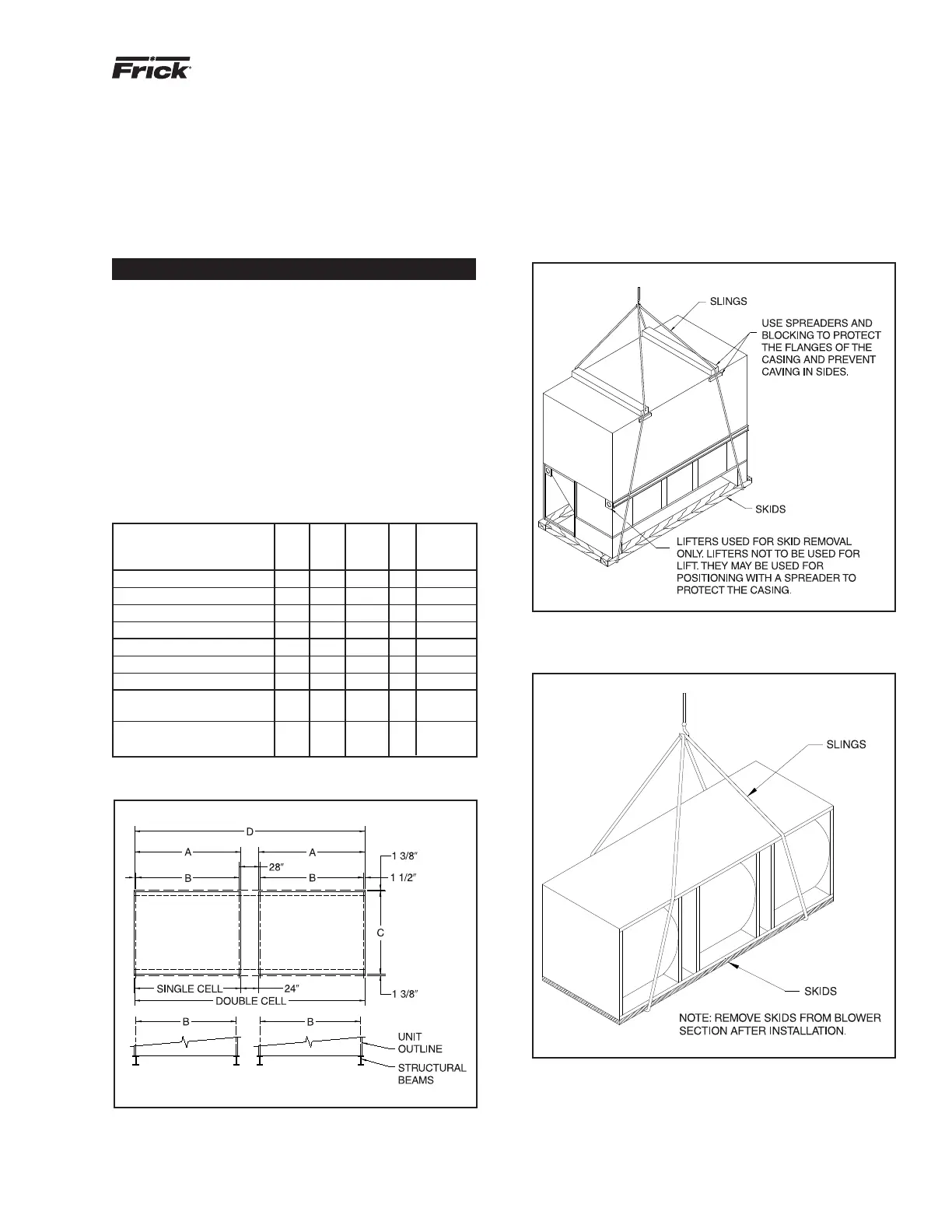

All units have 13/16 inch diameter mounting holes for mount-

ing to the beams. The beams should be supported so that the

unit is level. Shims between the beams and the unit should

not be used, as this will not provide adequate support.

If vibration isolation is required, whether furnished by Frick or

by others, the isolators must always be mounted below the

structural “I” beams. Continuous support of unit, as described

above, must be provided.

INSTALLATION

FOUNDATION LAYOUT INFORMATION FOR XLC UNITS

Beams and/or piers should be sized in accordance with

standard engineering practices, 55% of the operating weight

as a uniform load. Beam defl ection should not exceed the

larger of 1/360 of span or 1/2 inch. In Figure 2, “A” repre-

sents the overall length of one cell and “B” represents the

center lines of the mounting holes in the unit. The dashed

lines show the location of the structural beams to which the

unit is mounted.

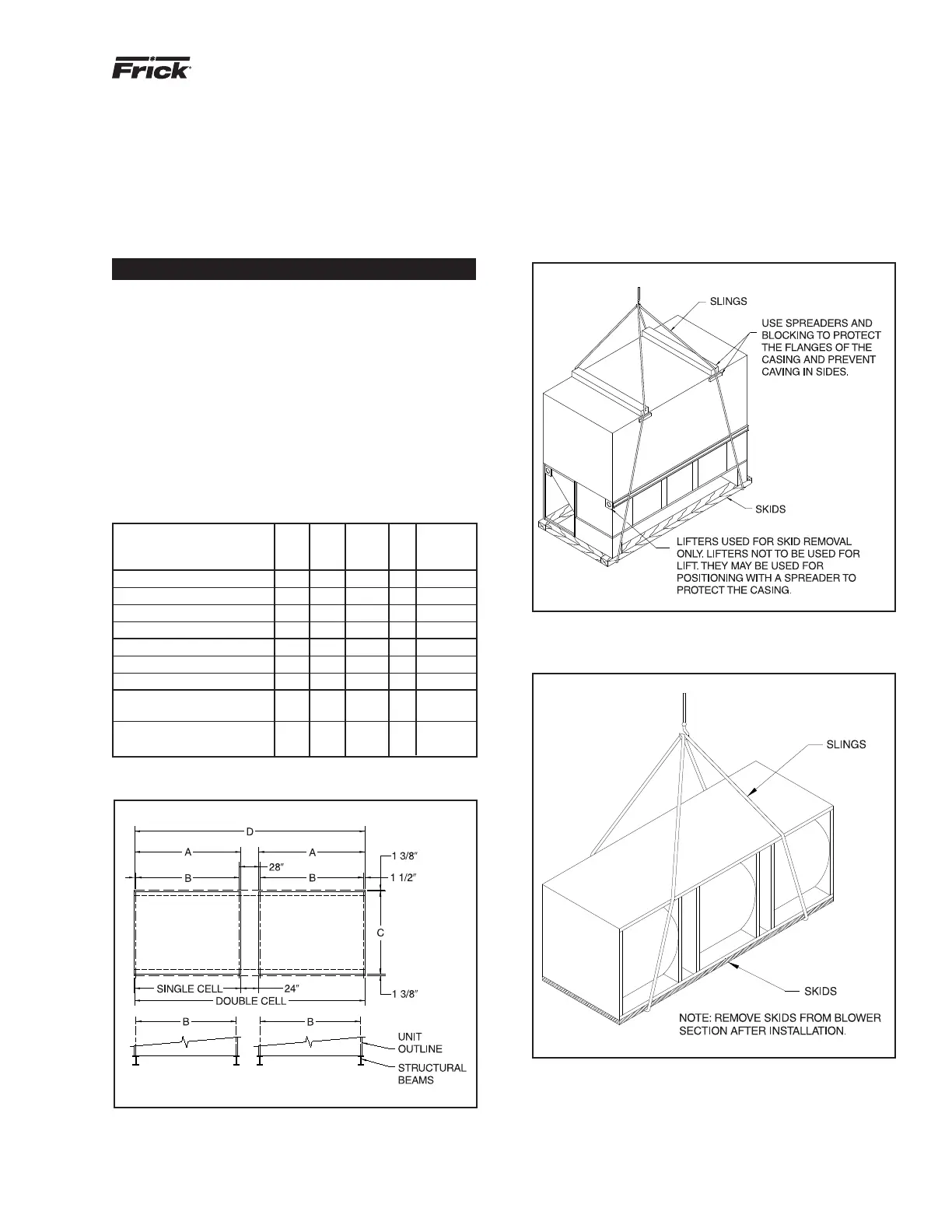

XLC CENTRIFUGAL FAN UNITS

XLC units are shipped in two pieces: the pan/coil section and

the fan section. The fi rst step of the installation is to mount

the pan/coil section on the structural beams and bolt it to the

beams. The rigging of the two pieces is shown in Figures 3a

and 3b. For minimum cable length, see Table 1.

Figure 2 - Platform Layout

Table 1

XLC FOUNDATION LAYOUT DIMENSIONS

MIN.

CABLE

MODEL A B C D LENGTH

XLC 25 through XLC 40 57 54 27.25 — 6 ft.

XLC 43 through XLC 55 57 54 38.75 — 6 ft.

XLC 58 through XLC 90 117 114 27.25 — 11 ft.

XLC 95 through XLC 128 117 114 38.75 — 11 ft.

XLC 130 through XLC 185 117 114 57.25 — 11 ft.

XLC 195 through XLC 250 117 114 80.25 — 12 ft.

XLC 285 through XLC 385 177 174 80.25 — 17 ft.

XLC 410-2

through XLC 500-2 117 114 80.25 258 12 ft.

XLC 570-2

through XLC 770-2 177 174 80.25 378 17 ft.

Figure 3a - XLC Pan/Coil Section Rigging

Figure 3b - XLC Fan Section Rigging

Loading...

Loading...