130 4280 010 E

Troubleshooting

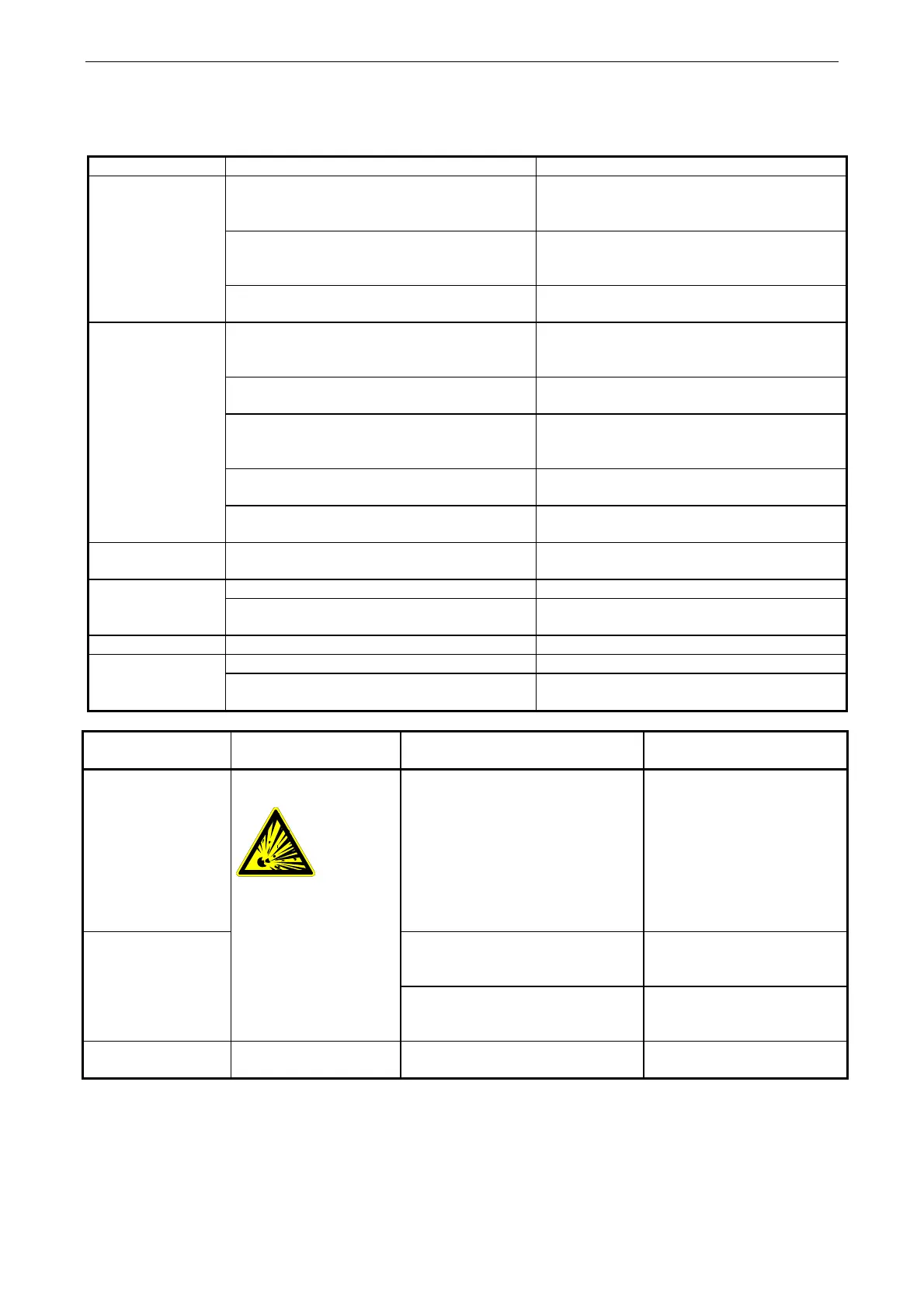

Symptom Possible Cause Corrective Action

Supply voltage incorrect or missing

Check switches, fuses, circuit breakers,

and actuator wiring connections (refer to

Table 1)

Flow rate set too low

Turn the ‘M’ adjustment screw

counterclockwise to increase the flow rate

(refer to chapter Adjustments)

Motor does not

run

Internal defect

Replace actuator (refer to chapter

Actuator Replacement)

Operating pressure too high

Verify that the maximum operating

pressure is not exceeded (refer to chapter

Specifications)

Incorrect mounting position of horizontal

actuator

Turn actuator. Observe mounting positions

as indicated on actuator label

Stroke setting set below 3 mm

Turn the ‘R’ or ‘S’ adjustment screw

counterclockwise to increase the stroke

(refer to chapter Adjustments)

Flow direction

Check flow direction: the flow direction is

indicated by an arrow on the valve body

Motor runs but

valve does not

open

Internal defect

Replace actuator (refer to chapter

Actuator Replacement)

Motor does not

turn off

Limit switch defective

Replace terminal box (refer to chapter

Repairs and Replacement)

Incorrect wiring Check wiring (refer to Table 1) Actuator moves

through Low

Position

Switch defect

Replace terminal box (refer to chapter

Repairs and Replacement)

Leakage Flanges, fittings Replace seals or screws or replace valve

Dirt on valve seat

Replace valve

Inner leakage

Flow direction

Check flow direction: the flow direction is

indicated by an arrow on the valve body

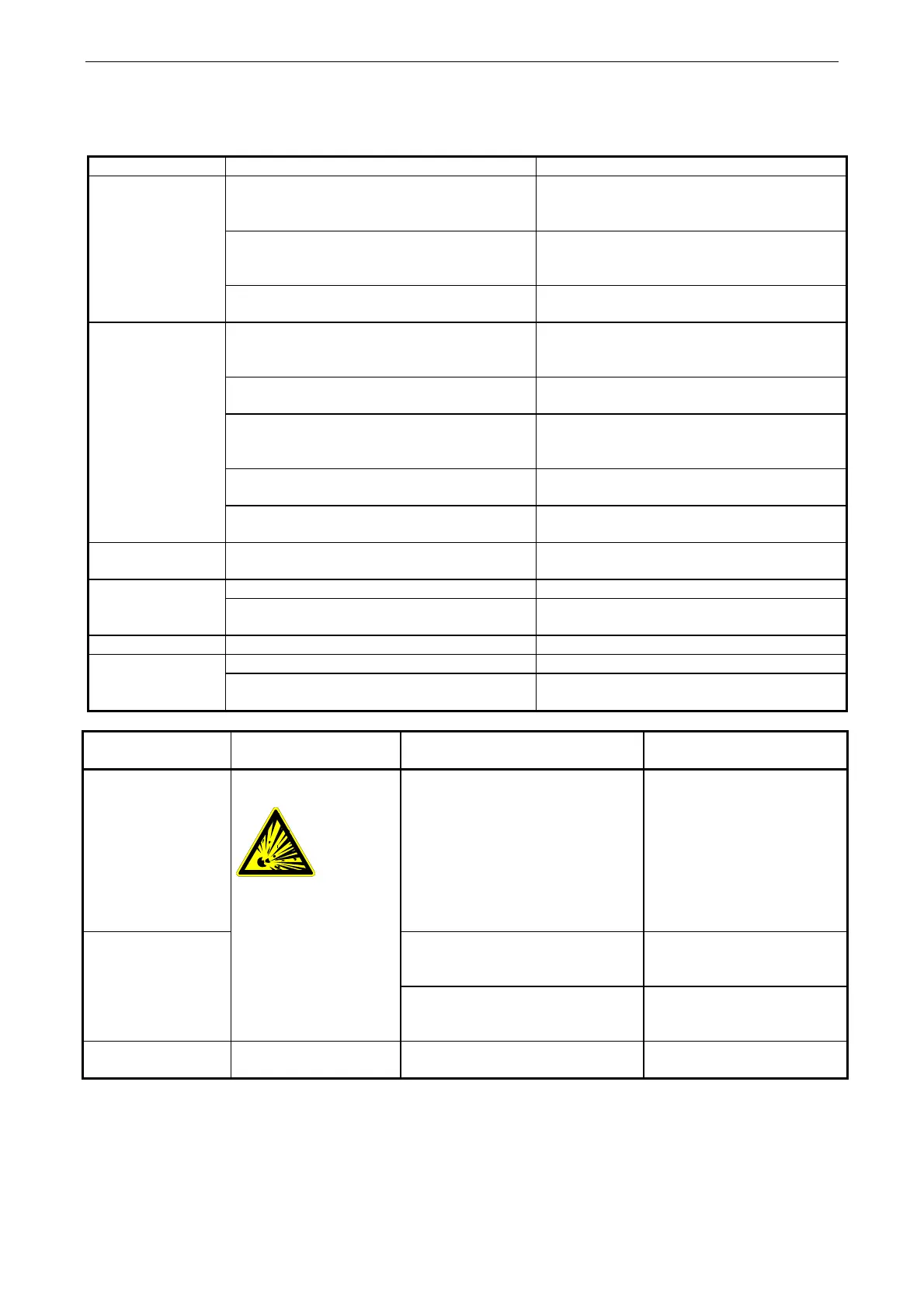

Fault diagnosis Effects Cause

Remedial

action/Minimising risks

Valve body,

flanges, actuator:

Cracks, holes,

damage, leakage

Piping stressed beyond permitted

limits, recoil forces, pressure

surges, valves used as fixed

point, not permitted pressure and

temperature limits

Reduce pressure and

stress, change piping

position, install

compensators, select other

materials. The piping must

meet all applicable

codes/standards (i.e. TRB,

TRR).

Replace valve

Improper transport, bending

stresses too great, thermal stress

Replace valve, ensure that

piping is laid free of stress

or tension

Flange fitting not

tight, leakage

Danger of explosion

Danger of flying

shrapnel, danger of

poisoning, burns

danger, environmental

pollution

Bolts not tightened diagonally

Proper installation in

accordance with these

operating instructions

Hot surface Burns danger

Wrong operating voltage,

actuator surface becomes hot

Replace actuator, check

operating voltage

Johnson Controls SA/NV - Leuvensesteenweg 248D - B-1800 Vilvoorde - +32(2) 709 40 00 - www.johnsoncontrols.be

Johnson Controls SA/NV - Leuvensesteenweg 248D - B-1800 Vilvoorde - +32(2) 709 40 00 - www.johnsoncontrols.be

Loading...

Loading...