6112628-UIM-B-0622

Johnson Controls Ducted Systems 9

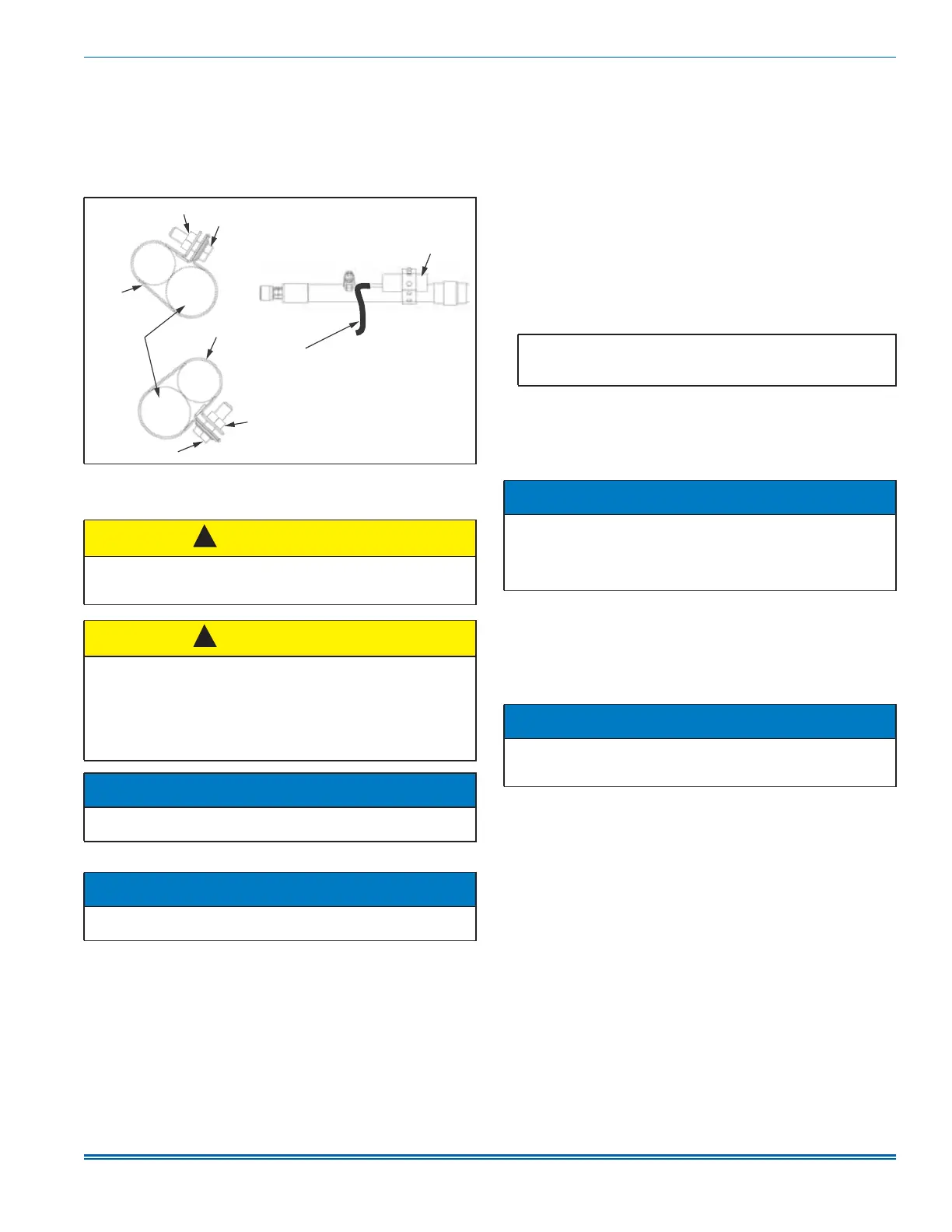

a. Install the TXV bulb on the vapor line suction header near the

TXV equalizer tube connection port. Ensure to install the bulb at

a 10 o’clock or 2 o’clock position.

b. Insulate the TXV bulb using the thermal insulation provided to

protect it from the effect of the surrounding ambient temperature.

Cover the bulb completely to insulate.

9. After installing the refrigeration piping, leak test the system.

Section VI: Refrigerant line connection

Connect lines as follows:

1. Make suction and liquid line connections outside of the cabinet.

Leave the tubing connection panel attached to the cabinet. Remove

the coil access panel for brazing. The lines are expanded to receive

the field refrigeration piping tubes for most outdoor unit matches.

2. Remove the grommets where the tubes exit the cabinet to prevent

burning them during brazing. In some units, the grommets may be

shipped as loose parts with the unit. See Figure 14.

3. Cut the end of the suction tube using a tube cutter. Place the tube

cutter as close as possible to the end of the tube to allow as much

depth as possible for the connection and brazing of the suction line.

To ensure the suction line fits into the connection, deburr the stub

out (including inner pressure protrusion from cutting).

4. If the coil does have a factory installed TXV or EEV, go to Step 5. If

the coil does not have a factory installed TXV or EEV, install the

required size piston or TXV kit. See Coil metering devices and Pis-

ton installation or Thermal expansion valve (TXV) installation for

detailed instructions.

5. If the coil does have a factory installed TXV or EEV, remove the liq-

uid line copper cap that is soft soldered onto the outside of the 3/8

in. stub protruding from the front of the coil cabinet tubing panel:

a. Screw a sheet metal screw into the center of the cap.

b. Apply a small amount of heat to the cap while pulling on the

screw using slip joint pliers.

Before brazing, connect and apply line power to the field wiring

terminals of the air handling unit and ensure the board is pow-

ered for 60 s. This ensures the EEV control board cycles the

valve to an open position. This allows nitrogen to flow through

the system during brazing.

6. Insert the liquid and suction lines into the coil connections at the coil

cabinet tubing panel.

7. Wrap a water-soaked rag around the coil connection tubes inside

the cabinet to avoid transferring excess heat to the coil, TXV, EEV,

and temperature sensor if the coil is equipped with an EEV.

8. Purge the refrigerant lines with dry nitrogen during brazing.

9. Braze the suction and liquid lines, and allow the joints to cool.

10. Secure the sensing bulb and equalizer line capillary tubes with

nylon cable ties to prevent leaks from tubes rubbing.

11. If using a piston, install a Schrader valve core into the suction

header and reinstall the cap.

12. Re-attach the grommets to the lines carefully to prevent air leakage.

In some units, the grommets may be shipped as loose parts with

the unit. See Figure 14.

13. Refer to the outdoor unit Installation Manual and complete evacua-

tion, a leak check, and charging instructions. Check all field brazed

joints and metering device connections.

14. Attach the coil access panel to the cabinet.

15. Ensure the lines are sound isolated by using appropriate hangers

or strapping.

Figure 13: Correct bulb location

CAUTION

The coil is under inert gas pressure. Relieve pressure from the coil by

depressing the Schrader valve core at the end of the suction manifold

stub out.

CAUTION

Dry nitrogen must always be supplied through the tubing while it is

being brazed, because the temperature required is high enough to

cause oxidation of the copper unless an inert atmosphere is provided.

The flow of dry nitrogen must continue until the joint has cooled.

Always use a pressure regulator and safety valve to insure that only

low pressure dry nitrogen is introduced into the tubing. Only a small

flow is necessary to displace air and prevent oxidation.

NOTICE

Avoid handling aluminum coil components after handling the copper

refrigeration piping or other tubing without first cleaning hands.

NOTICE

Route the refrigerant lines to the coil in a manner that will not obstruct

service access to the coil, air handling system, furnace flue, or filter.

A1672-001

Nut

Screw

Bulb at

10 o’clock

position

Clamp

Vapor line

Bulb at

2 o’clock

position

Screw

Nut

Clamp

TXV bulb

TXV sensing bulb

Indoor coil header assembly

(connecting bulb with evaporator TXV)

(header body)

!

!

Important: For EEV-equipped coils only

The EEV in this unit is shipped in the closed position to protect the

valve during transportation.

NOTICE

If power cannot be applied to the EEV control board prior to brazing

refrigeration piping, a tool is available to manually operate the EEV.

An EEV manual operating tool can be purchased from Source 1 as

part number S1-02649686000. Six revolutions of the tool opens the

valve fully.

NOTICE

All indoor coil connections are copper-to-copper and must be brazed

with a phosphorous-copper alloy material such as Silfos-5 or equiva-

lent. Do not use soft solder.

Loading...

Loading...