M Motor Actuators

—

Y20EBD Valve Linkage for M100 Motor Actuators 23

Checkout Procedure

After Installation and adjustment, run the system through several complete

open/close cycles to be sure that all components are functioning correctly.

Check to be sure that the actuator responds to the controller and operates

the valve properly. Check for proper voltage. Check for operation of the

linkage without binding.

!

CAUTION: The actuator should not be stalled by the valve. The

actuator may be damaged if it is not free to complete

its full stroke.

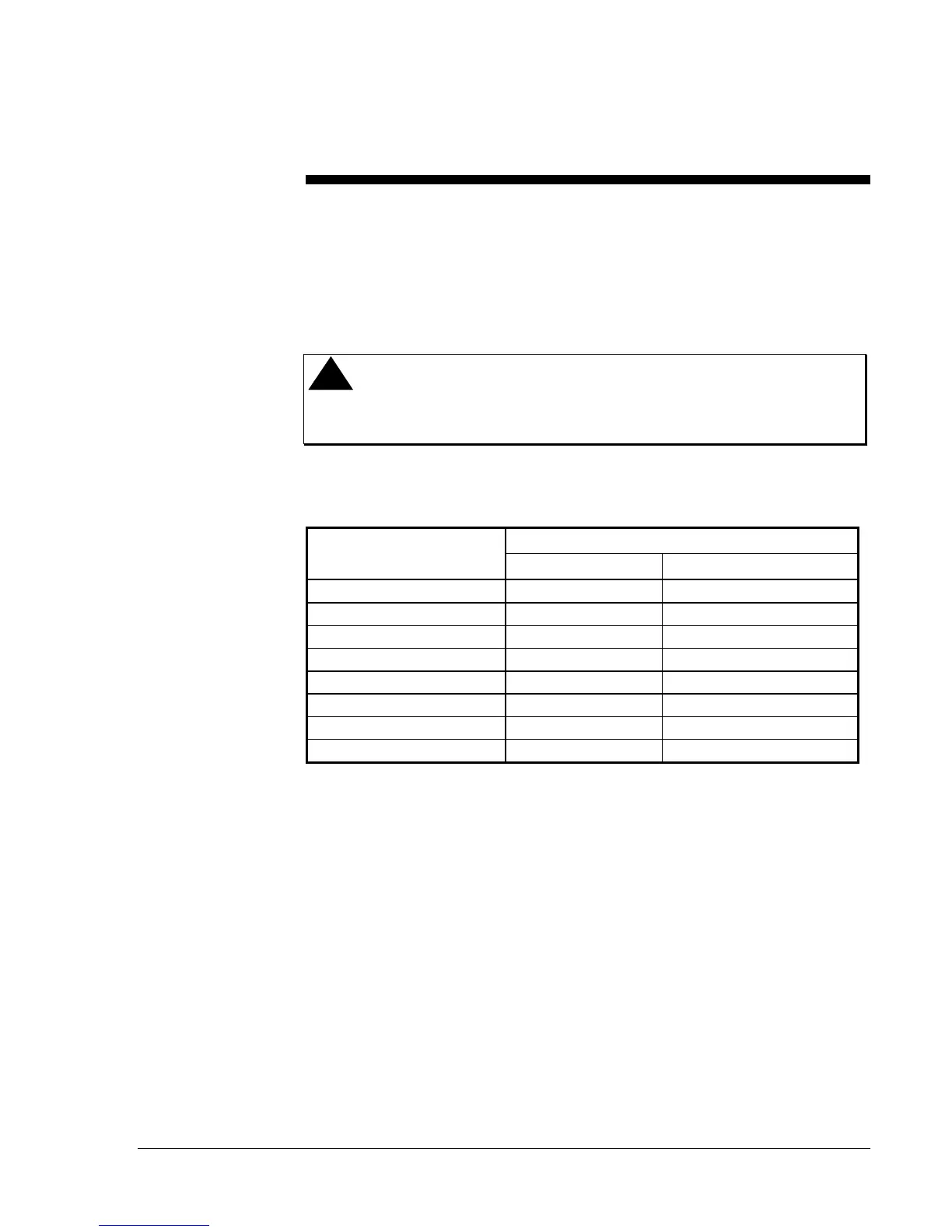

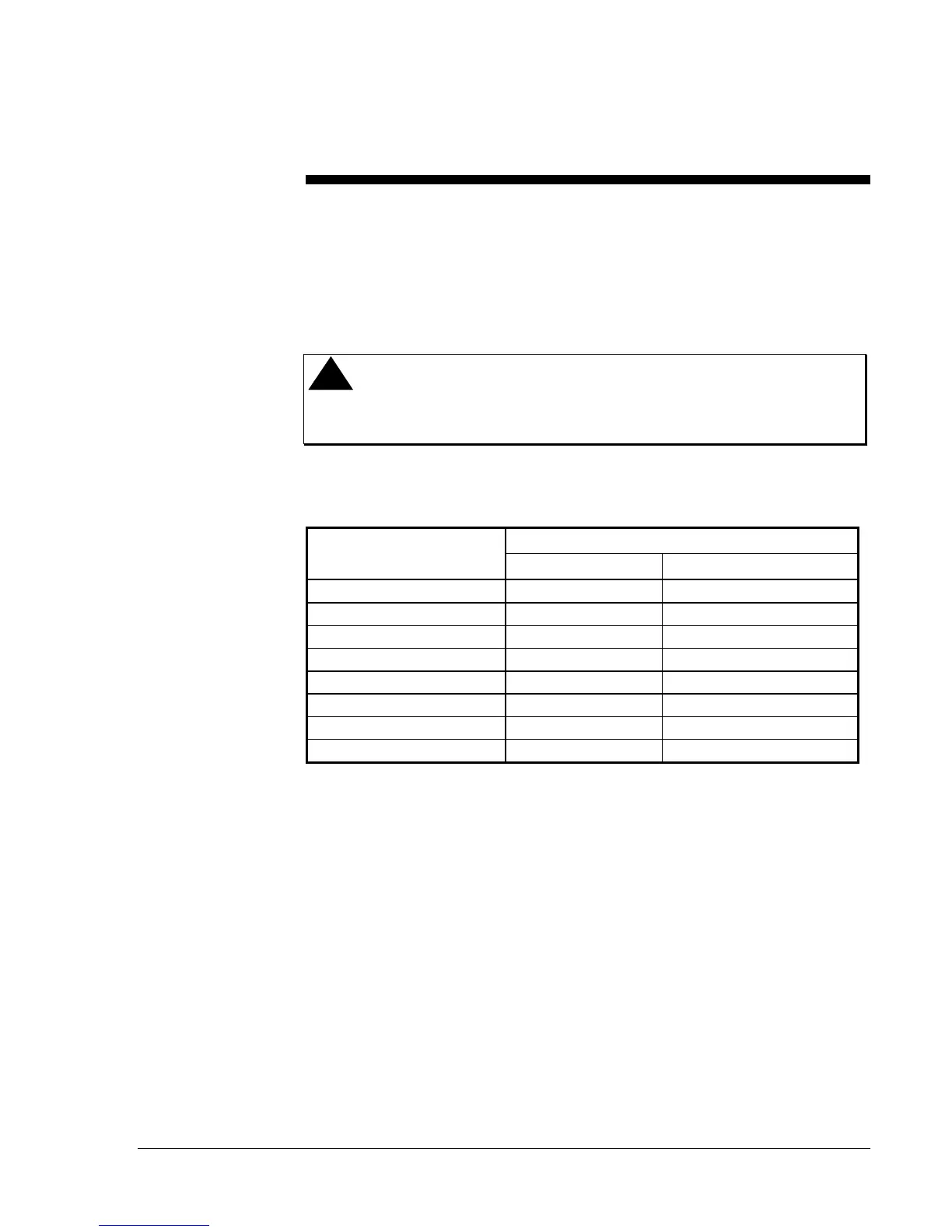

Table 2: Actuator Connections for Travel Limit Adjustment

Jumper Terminals

Model Clockwise (CW) Counterclockwise (CCW)

M100A

1 and 2 1 and 3

M100C

COM to CW COM to CCW

M100E

S1 to S2* Disconnect S1, S2, A, C

M100F

8 and 9 8 and 10

M100G or M100H

8 to T1 8 to 10

M100J

8 and 9 8 and 10

M100Q

8 to T1 8 to 10

M100M

R to B Disconnect R from B

*

Apply 24 VAC to relay terminals A and C for clockwise rotation.

Note: On all models, remove controller wires and apply 24 VAC to

terminals T1 and T2 while making adjustments. Spring return

models will go full CCW when power to T1 and T2 is removed.

Loading...

Loading...