POWERHEAD

ASSEMBLY - 25/30

Thoroughly clean

and

degrease the mating

flanges of the crankcase

and

cylinder block with

Cleaning Solvent and let air

dry.

Apply Locquic Primer

to

the

mating flanges of the

cylinder block and crankcase

and

let air

dry.

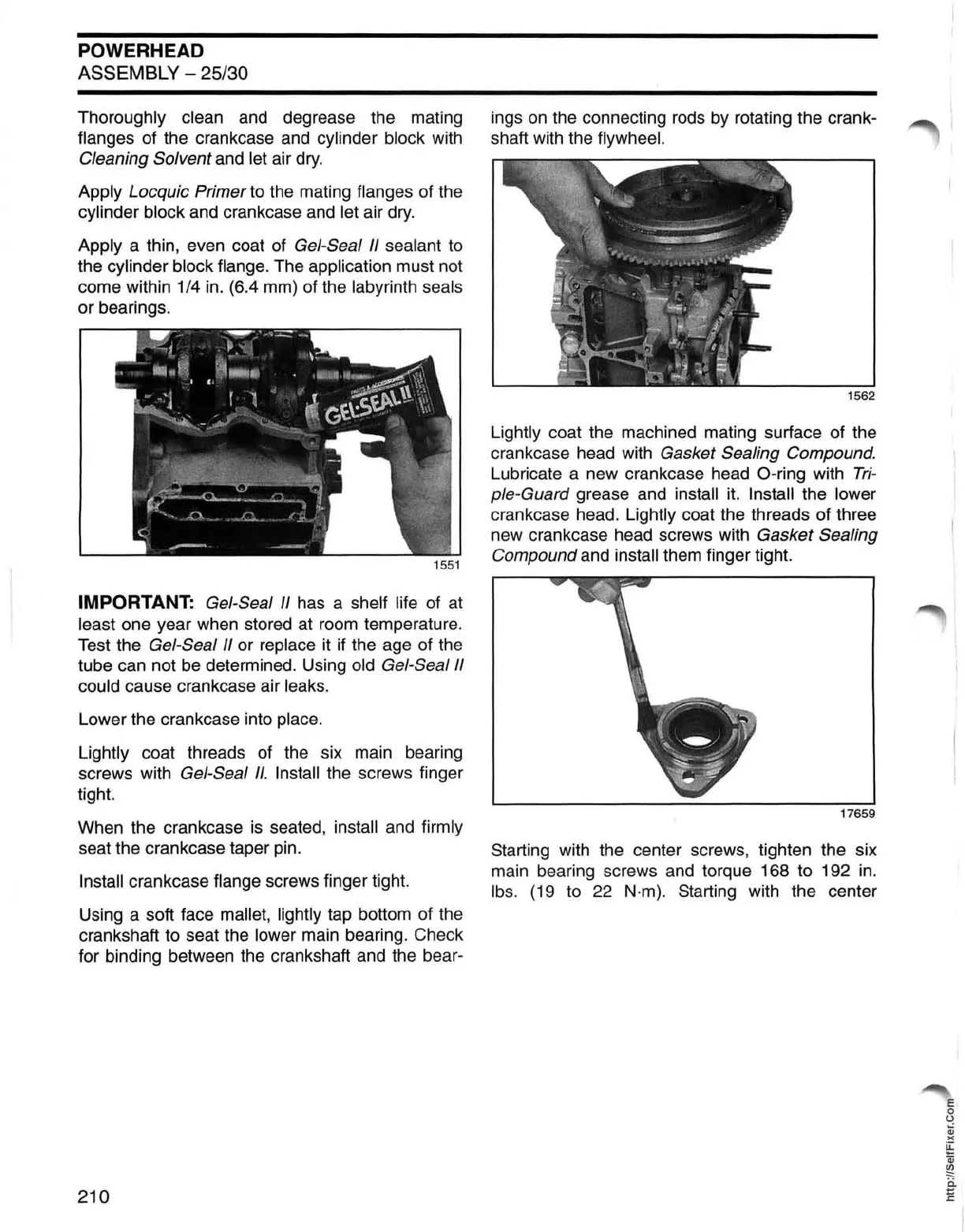

Apply a thin, even coat of Gel-Seal II sealant

to

the cylinder block flange. The application must not

come within

1/4

in.

(6.4

mm)

of the labyrinth seals

or bearings.

IMPORTANT: Gel-Seal II has a shelf life of at

least one year when stored at

room

temperature.

Test the

Gel-Seal II or replace it if the age of the

tube can not

be

determined. Using old Gel-Seal II

could cause crankcase air leaks.

Lower the crankcase into place.

Lightly

coat threads of the six main bearing

screws with

Gel-Seal

II.

Install the screws finger

tight.

When the crankcase

is

seated, install

and

firmly

seat the crankcase taper

pin.

Install crankcase flange screws finger tight.

Using a soft face

mallet, lightly tap bottom of the

crankshaft to seat the

lower main bearing. Check

for binding between the crankshaft and the bear-

210

ings

on

the connecting

rods

by rotating the crank-

shaft with the

flywheel.

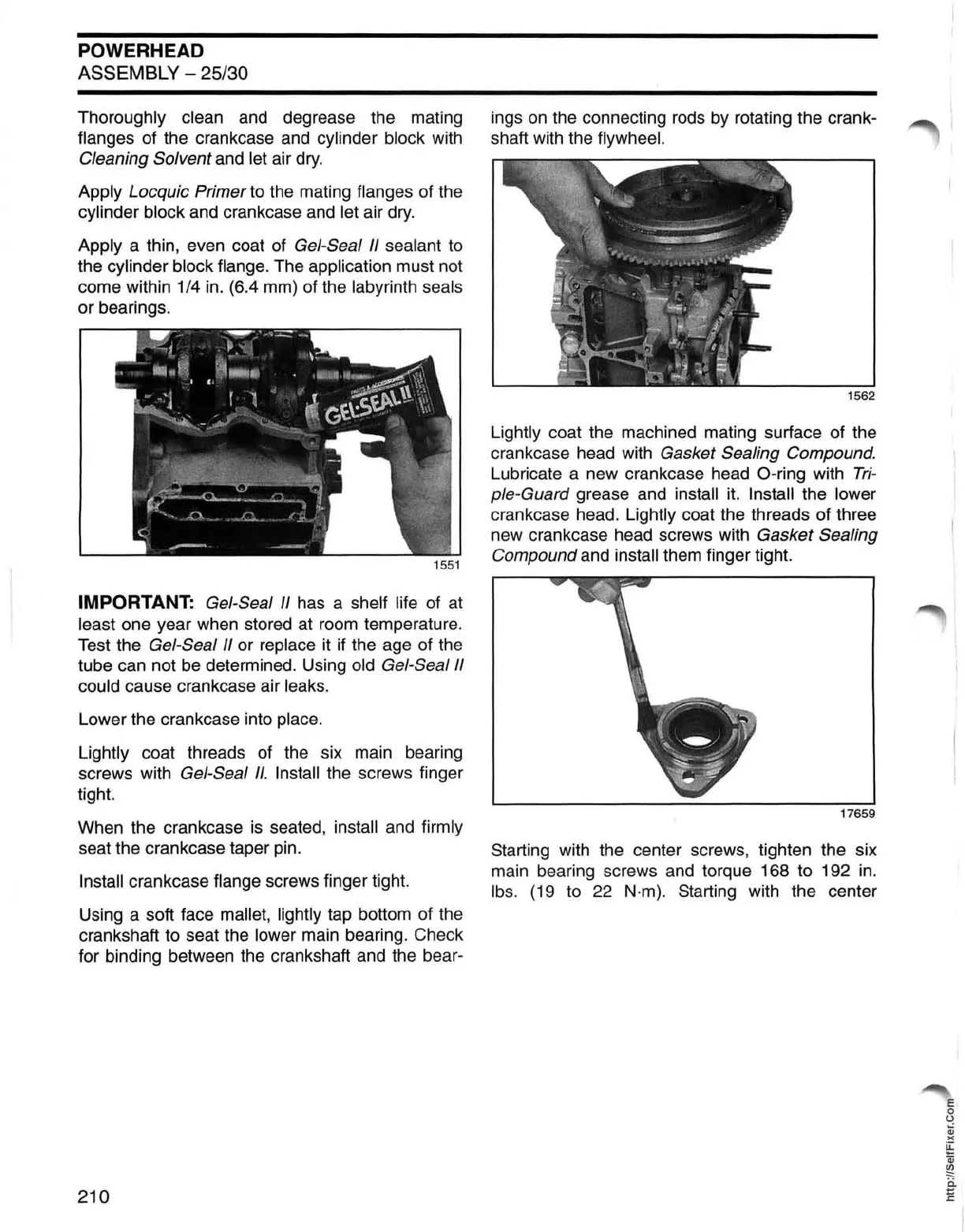

Lightly

coat the machined mating surface of the

crankcase head with

Gasket Sealing Compound.

Lubricate a new crankcase head O-ring with

Tri-

ple-Guard grease

and

install

it.

Install the lower

crankcase head. Lightly coat the threads of three

new crankcase head screws with

Gasket Sealing

Compound and install them finger tight.

Starting with the center screws, tighten the six

main bearing screws

and

torque 168

to

192

in.

Ibs.

(19

to

22

N·m). Starting with the center

Loading...

Loading...