13

ENGLISH

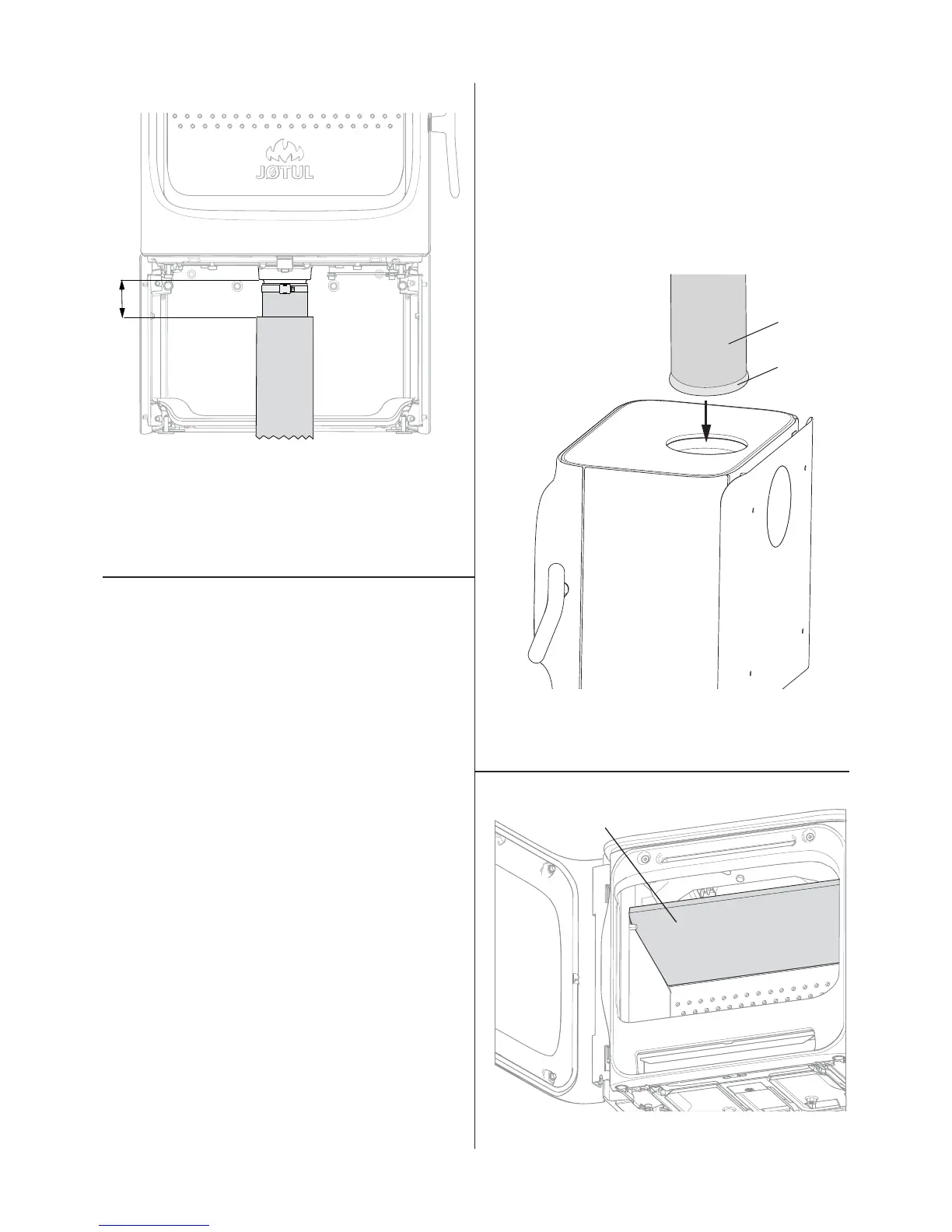

Fig. 17

100

4. See the installation instructions that follow with the external

air set.

5. Attach the hose to the external air connector with a hose

clip to avoid using joints. The external air hose insulation

ends approx. 100 mm below the burn chamber.

4.4 Chimney and fl ue pipe

• The fi replace must only be connected to a chimney and

fl ue pipe approved for solid fuel fi replaces with fl ue gas

temperatures as specifi ed in «2.0 Technical Data».

• The cross-section of the chimney must be designed to fi t

the fi replace. Use «2.0 Technical Data» to calculate the

correct chimney cross-section.

• The chimney must be connected in accordance with the

installation instructions of the chimney supplier.

• Before a hole is made in the chimney, the product should

be test-mounted in order to correctly mark the position of

the fi replace and the hole in the chimney. See fi g. 1 for

minimum dimensions.

• Make sure that the fl ue pipe rises all the way up to the

chimney.

• With a rear outlet, use a fl ue pipe bend with a sweep hatch

to allow sweeping.

• Please note that it is extremely important for connections

to have a degree of fl exibility. This is to prevent any

movement in the installation leading to the formation of

cracks.

• For recommended chimney draught, see «2.0 Technical

Data». For fl ue pipe dimension see “2.0 Technical Data”.

NB: The chimney’s diameter must be at least just as

big as the fl ue pipe.

NB! The minimum recommended chimney length is 3.5 m

from the fl ue pipe insert. If the draught is too strong, a fl ue

pipe damper can be installed and used to reduce the draught.

Protection grid for sweep ball

When a steel chimney is installed to the top outlet, a

protection grid for sweep ball must always be installed to

the top outlet (optional equipment).

4.5 Fitting a fl ue pipe with a top outlet

The product is supplied from the factory with the smoke outlet

fi tted for the top outlet.

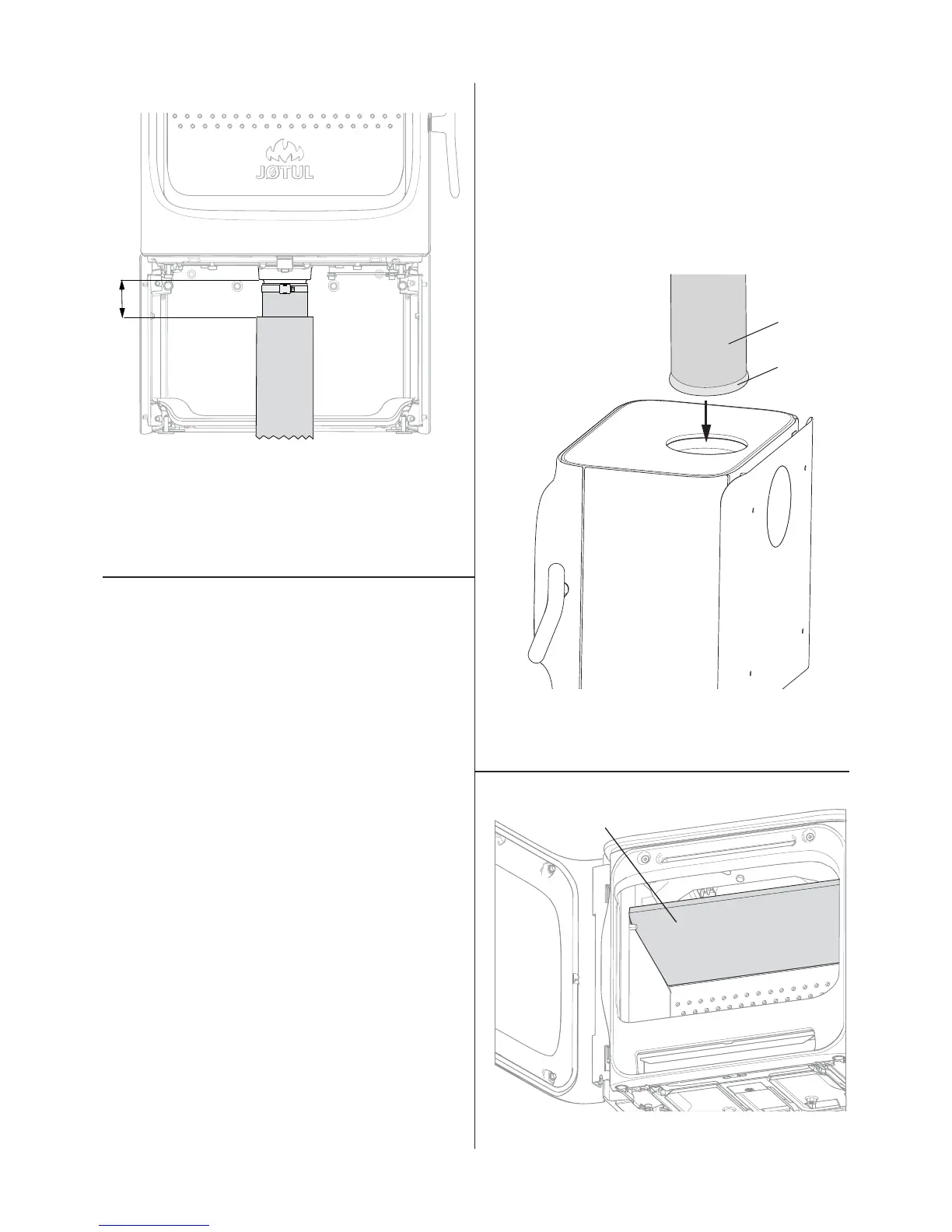

Fig. 18

A

B

1. Thread the fl ue pipe (A) through the top plate and place it

in the top smoke outlet.

2. Seal well with a gasket (B).

Fig. 19

A

3. Place the baffl e (A) as displayed in the fi gure.

Loading...

Loading...