Do you have a question about the JPT Seal-355-5 and is the answer not in the manual?

Details the features, benefits, and applications of the Seal-355-3/5 series UV lasers.

Presents a detailed list of technical parameters for the Seal-355-3/5 series lasers.

Provides diagrams showing the physical dimensions and mounting requirements for the laser.

Step-by-step instructions for installing the laser head, chiller, and power supply.

Explains the Graphical User Interface for internal debugging and monitoring of the laser system.

Details the laser interface ports, indicator lights, and their functions.

Describes how to control laser emission, frequency, and power using Gate and PWM signals.

Explains the timing requirements for GATE and TRIG signals for external laser control.

Guides on connecting JCZ and SAMlight control cards to the laser system.

Step-by-step instructions for safely powering on the laser system and associated components.

Details the correct procedure for safely shutting down the laser system.

Highlights key safety recommendations and precautions during laser operation.

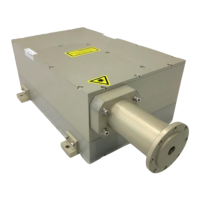

The JPT Seal-355-3/5 and Seal-355-3/5-S are UV solid-state lasers designed for precision material processing. These lasers are utilized in applications such as micro-machining, micro-hole drilling, cutting, and scribing across various materials including metal, semiconductor materials, ceramic, glass, and polymer. The UV laser's short wavelength, small spot size, and intense energy allow for high-resolution processing, narrow line widths, and minimal thermal effects, resulting in high-quality marking and processing.

The JPT Seal-355-3/5 series UV lasers operate by directly breaking chemical bonds in the target material, which generates significantly less heat compared to IR lasers. This minimizes thermal effects and reduces contamination by turning processed material into atomic-level particles. The lasers are end-pumped solid-state devices with a stable and compact resonator design, contributing to high laser efficiency, good beam quality, and stability. They are designed for long lifetime and are maintenance-free. The internal LD (Laser Diode) design within the chamber reduces fiber interference. The new All-In-One (AIO) design is space-saving and offers enhanced anti-interference capabilities.

The Seal-355-3/5S, an upgraded version, features excellent beam quality (M² < 1.2) and spot characteristics (circularity > 90%). Its integrated structure combines optical and external driving circuits, providing strong anti-interference. The fully sealed structure prevents external dust entry, and the isolation from external water molecules provides strong anti-moisture characteristics, making the Seal series suitable for harsh industrial environments. A self-cleaning system for the intracavity further extends the service life. The Seal-355-3/5S series also boasts very short pulse widths (<10ns@60KHz) and excellent pulse stability (<3% RMS@60KHz) at medium and high repetition frequencies.

The laser emission and turn-off are controlled by a GATE signal. Laser frequency, power, and other parameters are set via a PWM (Pulse Width Modulation) signal, by adjusting the PWM frequency and duty cycle. The duty cycle is defined as the ratio of the high voltage time to the PWM period. For example, a PWM frequency of 50KHz (20µs period) with a 6µs high voltage time results in a 14µs low voltage time, giving a 3:10 duty cycle. In specific frequency conditions, a 1µs high voltage on the laser PWM signal corresponds to 100% ADJUST, which yields the largest power, smallest pulse width, and peak power for that frequency. Reducing the ADJUST value (increasing high voltage related pulse width) decreases laser power and increases pulse width. The PWM signal, through frequency and duty cycle adjustments, allows control over laser pulse frequency, power, and pulse width.

The Seal-355-3/5 series includes several models: Seal-355-3 (3W UV-AIO), Seal-355-5 (5W UV-AIO), Seal-355-3-S (3W UV short pulse width), and Seal-355-5-S (5W UV short pulse width).

The laser is intended as a component for incorporation into a larger laser product, requiring additional safety features to comply with IEC/EN60825-1 and 21 CFR1040.10. It is classified as a Class IV invisible laser, meaning direct, reflected, or scattered laser radiation can cause severe damage to eyes and human tissue. Laser safety glasses must be worn during operation. Flammable or explosive materials, as well as black paper, cloth, or leather, should not be in the light path. Even the pilot beam emits weak UV laser radiation.

The device features a GUI (Graphical User Interface) for internal debugging and monitoring, though all parameters are pre-debugged before shipment, so customer interaction with the software is generally not required. External control signals are used for operation.

The laser enclosure is not designed for customer access or maintenance. All maintenance and service, including upgrades, can only be performed at the JPT factory or on-site with technical support. Opening the laser enclosure without JPT factory permission will void the warranty. The Seal-355-3/5S models incorporate a self-cleaning system for the intracavity to prolong service life and are designed with a fully sealed structure to prevent dust and moisture ingress, enhancing reliability in harsh industrial environments.

| Brand | JPT |

|---|---|

| Model | Seal-355-5 |

| Category | Measuring Instruments |

| Language | English |