– 117 –

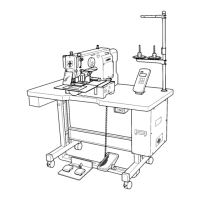

1-3. Adjusting the vertical stroke of the intermediate presser

* Turn ON the power once, and turn OFF the

power again after making the intermediate

presser in the lowered state.

1) Remove face cover.

2) Turn handwheel to make the needle bar come

down to its lowest point.

3) Loosen hinge screw

and move it to the di-

rection A to increase the stroke.

4) When marker dot

is aligned with the right

side of the outer periphery of washer

, the

vertical stroke of the intermediate presser

becomes 4 mm. And, when marker dot

is

aligned with the right side of the outer periphery

of the washer, it becomes 7 mm. (The vertical

stroke of the intermediate presser is factory-set

to 4 mm at the time of delivery.)

By removing the rubber plug in the face plate

cover, adjustment can be performed without

removing the face plate cover.

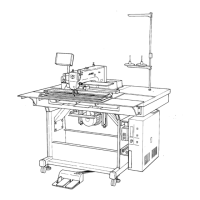

1-2. Adjusting the height of the feeding frame

1) Loosen setscrews

located on the right and left

sides of feed bracket

. Moving cloth presser

link

to the direction A will decrease the height

of the feeding frame.

2) After the adjustment of the height of the feeding

frame, securely tighten the screws

.

If the feeding frame still interferes with the face

plate bearing and the feeding frame height does

not change after the adjustment of the position

of work clamp link, adjust the pressure applied

to the face plate bearing to lower it as far as no

lateral play of the feeding frame occur.

At the time of delivery, work clamp foot has been

moved up and down to adjust the torque (sliding

torque) of face plate bearing

to 0.98 to 7.84 N (100

to 800 g) applied when work clamp foot starts mov-

ing after face plate bearing

has come in contact

with the spring pin.

1. Loosen the setscrew

.

2. Lightly tighten the pressure adjusting screw

and give a pressure to the face plate

bearing

. At that time, move the presser

foot face plate

vertically, making sure that

uneven application of torque can be avoided.

3. Tighten the setscrew

.

1. When the setscrew

is tightened,

pressure kept applied to the face

plate bearing

is changed.

Therefore, when the setscrew

is

tightened, examine the amount of

the slippage torque.

2. The pressure adjusting screw

is

not attached to the sewing machine.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

A

A

(SM6050660TP)

Loading...

Loading...