I

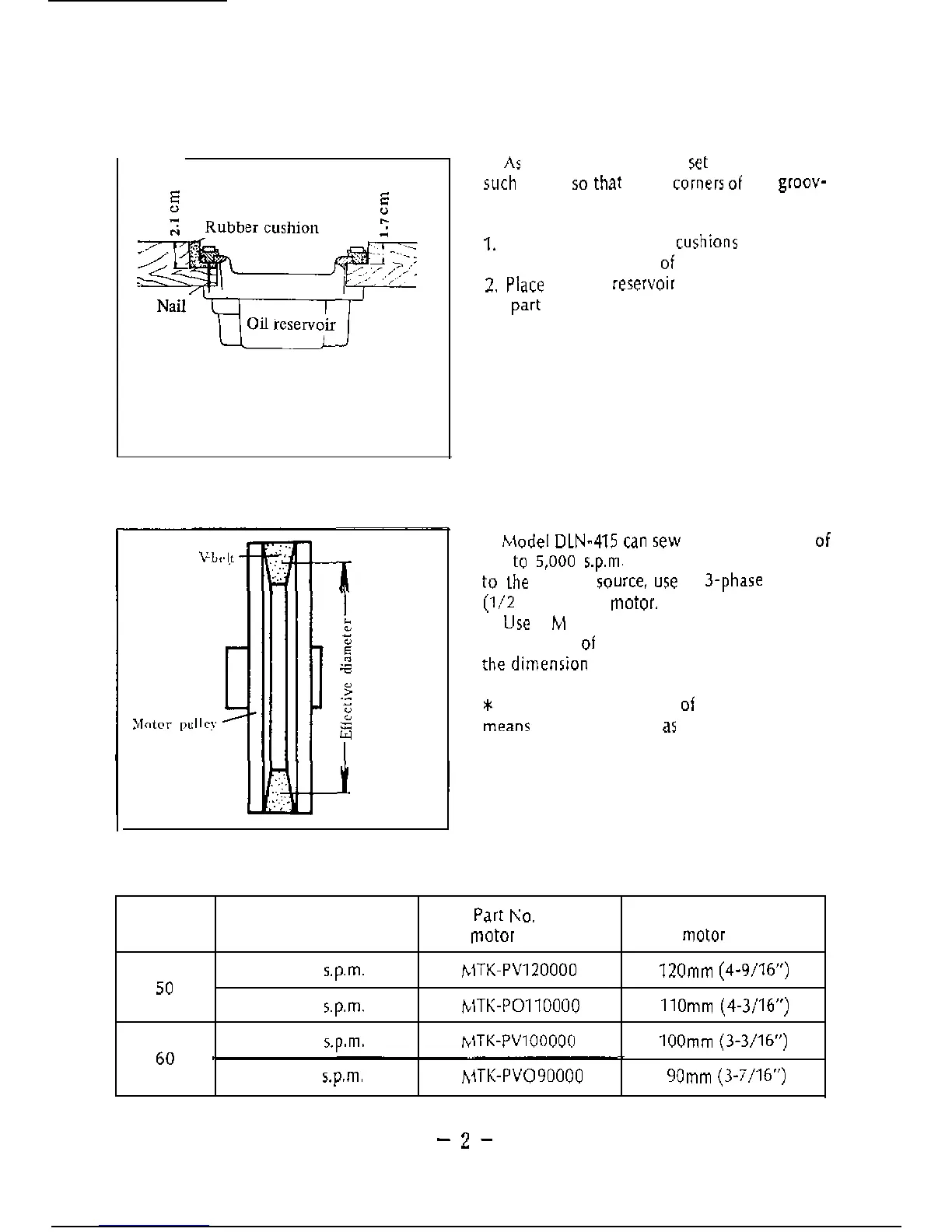

INSTALLING THE OIL RESERVOIR

Operator side

Hinge side

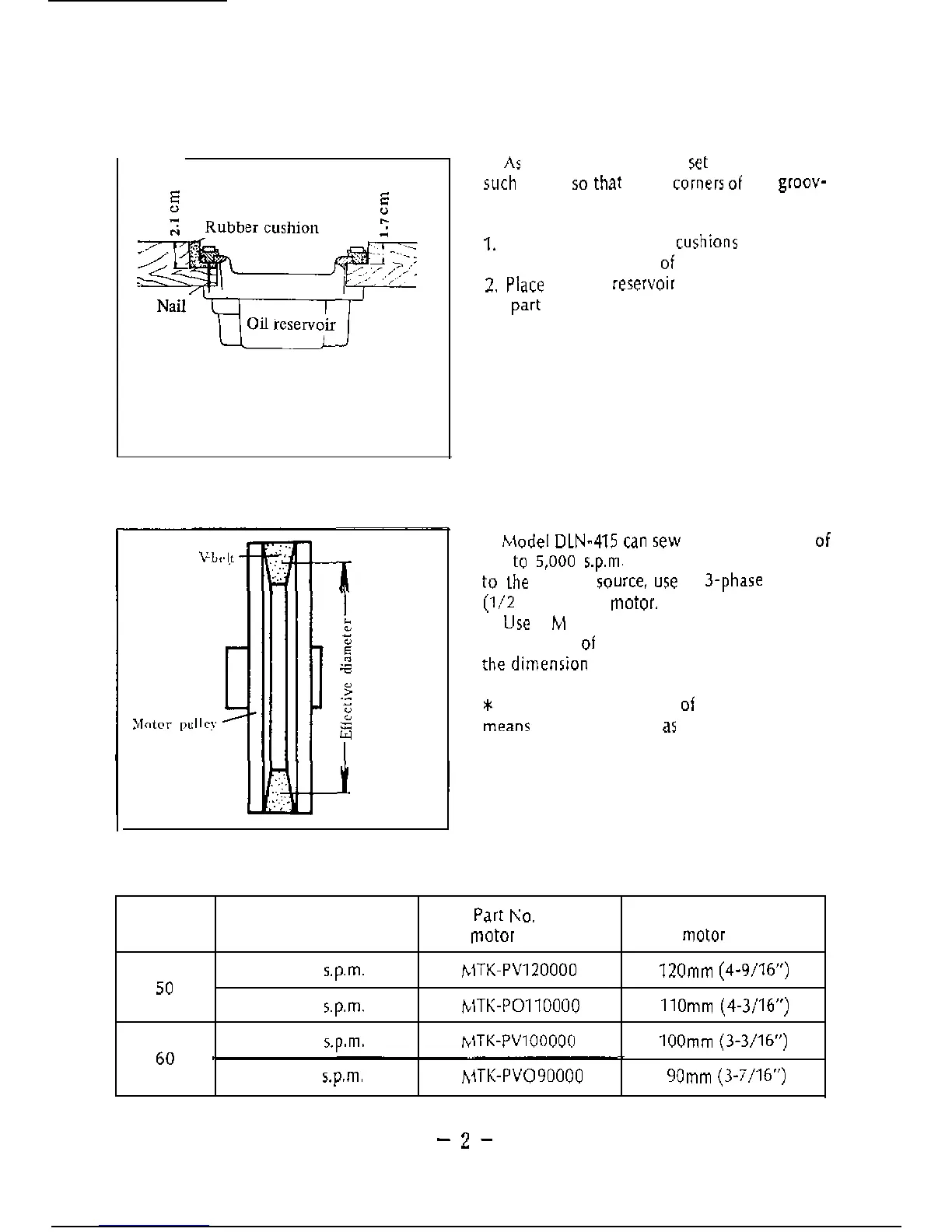

MOTOR PULLEY AND THE BELT

As

shown in the figure.

set

the reservoir in

such

a way

50

that

the 4

corners

01

the grow-

ed part of the table will be supporting the

reservoir.

1.

Nail in the 2 rubber

cushionr

in front to

the protruding part

01

the table.

2.

place

the oil

reservoir

on the protruding

part of the table.

,b,ade,

~Lt4-4,5

can

sew

at a high speed oi

up

to

5.000

r.p.m.

When connected directly

to

the

power

source.

use

a 3-phase 400 W

(l/2

HP) clutch mata.

Use a

hl

type V-belt. The relation between

the number

oi

rotation oi the machine with

the

dimenrion of the motor pulley is shown in

the table. (Effective diameter)

*

The effective diameter

oi

the motor pulley

rnGk”S

the diameter

a~

measured from the

center of the V-belt when the belt is wound

around the machine.

Cycle

50

60

No. of rotation

of machine

5.060

5.p.m.

4,630

5.p.m.

5,040

5.p.m.

4,540

5.p.m

Part

KO.

of

mOtol

pulley

MTK-P”120000

MTK-P0110000

MTK-P”,O”OOC

hlTK-P”090000

Effective diameter

of

motor

pulley

120mm

(4-9/W)

IlOmm (43/16”)

~lOOnlrn

(3.3/16”)

90mm

(3-T/16”)

-2-

Loading...

Loading...