−40 −

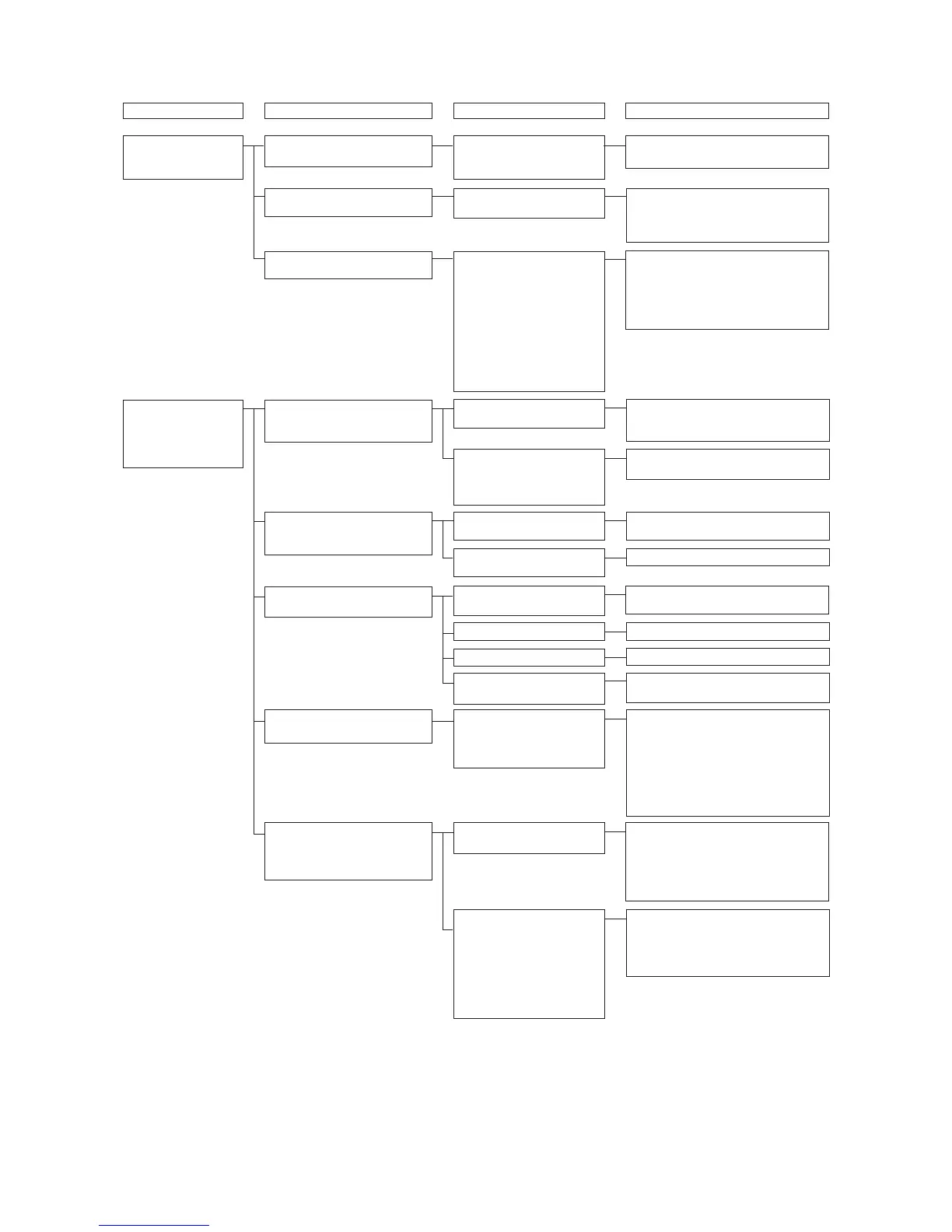

Cause (1)Troubles

Cause (2)

Corrective measures

6. Bobbin thread is not

cut. (Needle thread

is cut.)

7. Thread trimming is

not completed.

(Noise occurs from

the motor at the time

of thread trimming.)

6-1) Receding amount of moving

knife is insufficient.

6-2) Position of bobbin thread is

unstable.

6-3) A part of cutting blade

section of knife is dull.

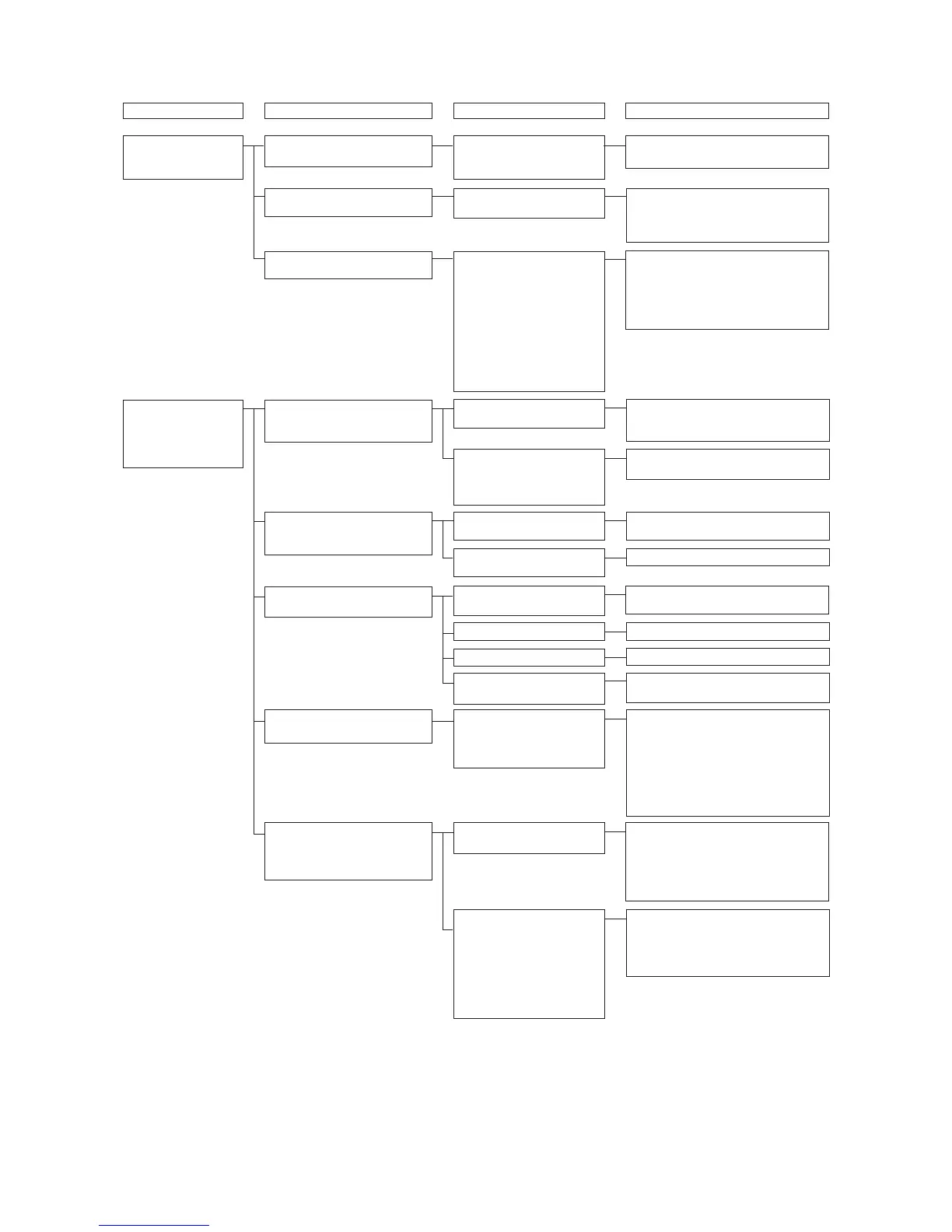

7-1) Amount of needle thread at

the time of thread trimming

is insufficient.

7-2) There is no allowance of

angle from thread trimming

to UP stop.

7-3) Force of motor is not

transmitted well.

7-4) Number of revolutions of

thread trimming is low.

7-5) Thread tension No. 1 is

excessively tightened to

prevent rough motion of

needle thread.

1)-A Needle thread only is

caught when moving

knife returns.

2)-A There is no groove for

guiding bobbin thread.

3)-A Cutting blade sections of

moving knife and

counter knife are not

completely fit at the time

of thread trimming.

(Installing angle,

position and inclination

of blade plane of counter

knife is not fit for the

blade section of moving

knife.)

1)-A Tension release timing

is too late.

1)-B Rising amount of disk at

the time of tension

release is small or the

disk is not rising.

2)-A Thread trimming timing

is too late.

2)-B Angle of UP stop is too

early.

3)-A Diameter of motor pulley

is too large.

3)-B Belt tension is low.

3)-C Inferior belt is used.

3)-D GAIN setting of control

box is improper.

4)-A Setting of number of

revolutions of thread

trimming of control box

is improper.

5)-A Oil amount in the hook is

small.

5)-B Height of needle bar is

improper and when it is

in the lower dead point,

needle thread is locked

and becomes resistance

since needle thread is

pinched with needle

hole and needle guard.

Correct the receding amount of moving

knife according to 4-(4).

Check whether there is the groove for

guiding bobbin thread in the hook. If not,

replace the hook with one for thread

trimming.

Remove the throat plate, and move the

moving knife by hand. It is good that 3 pcs.

of cotton thread #50 are evenly cut when

3 pcs. of the thread are cut. If not, adjust

the position and sharpening procedure of

counter knife according to 4-(7) and 6-(1).

Check the set value of LS (Output start

angle of L output of G mode) according to

5.

Adjust the rising amount of disk according

to 4-(9).

Correct the thread trimmer cam timing

according to 4-(6).

Correct UP stop timing according to 4-(3).

Use the pulley (mark : 105) supplied as

accessories.

Correct the belt tension according to 4-(16).

Use the belt supplied as accessories.

Check the set value of GA (changeover of

high/low GAIN of A mode) according to 5.

Check the set value of T (setting of number

of revolutions of thread trimming of P

mode) according to the Instruction Manual.

Normally 200 rpm is set. However,

increase the number of revolutions of

thread trimming within the tolerance of

idling of bobbin at the time of thread

trimming.

After adjusting oil amount in the hook

according to the Instruction Manual,

decrease the tension of thread tension

No. 1 within the range where thread

does not move roughly between thread

tensions No. 1 and No. 2.

After adjusting the height of needle bar

according to 4-(21), decrease the tension

of thread tension No. 1 within the range

where thread does not move roughly

between thread tensions No. 1 and No. 2.

Loading...

Loading...