−39 −

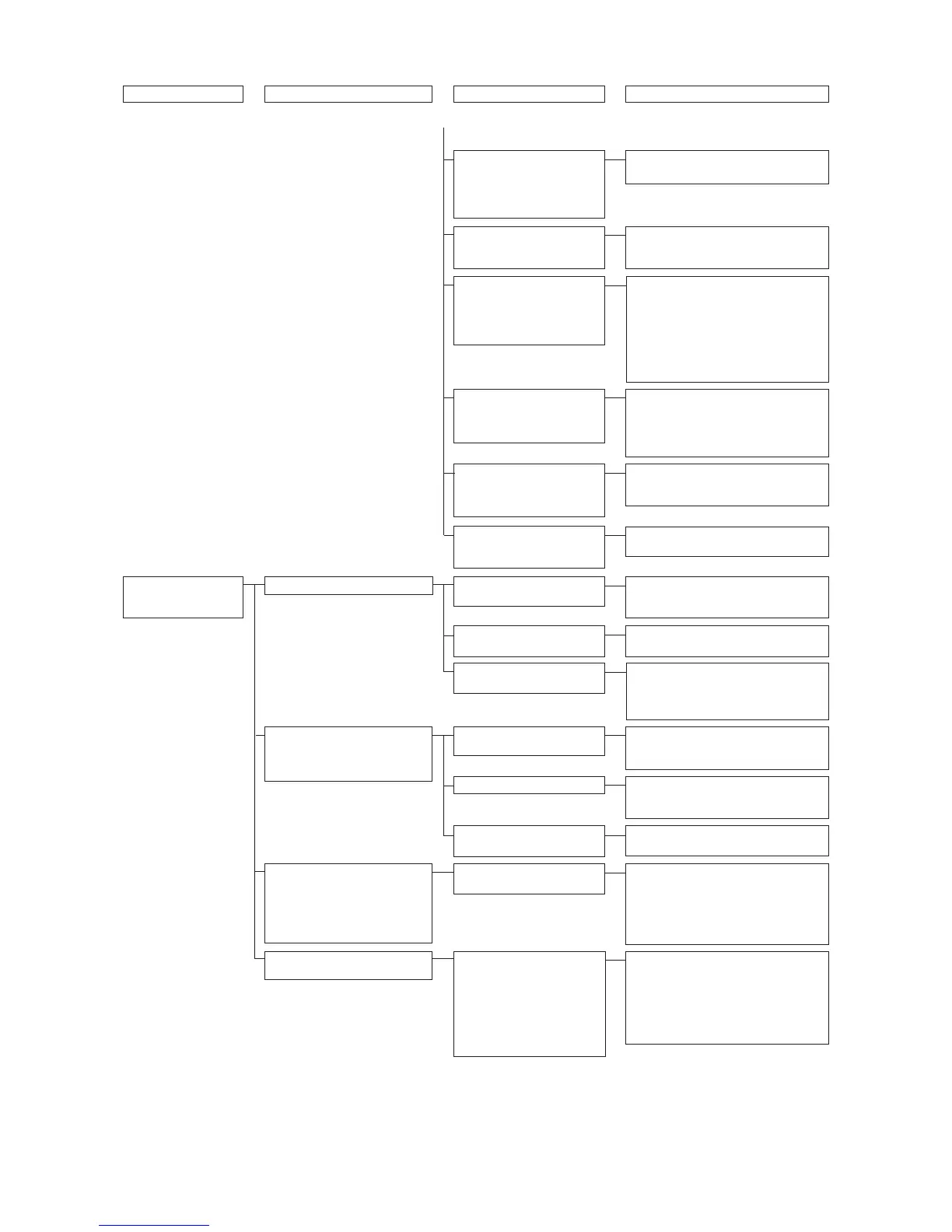

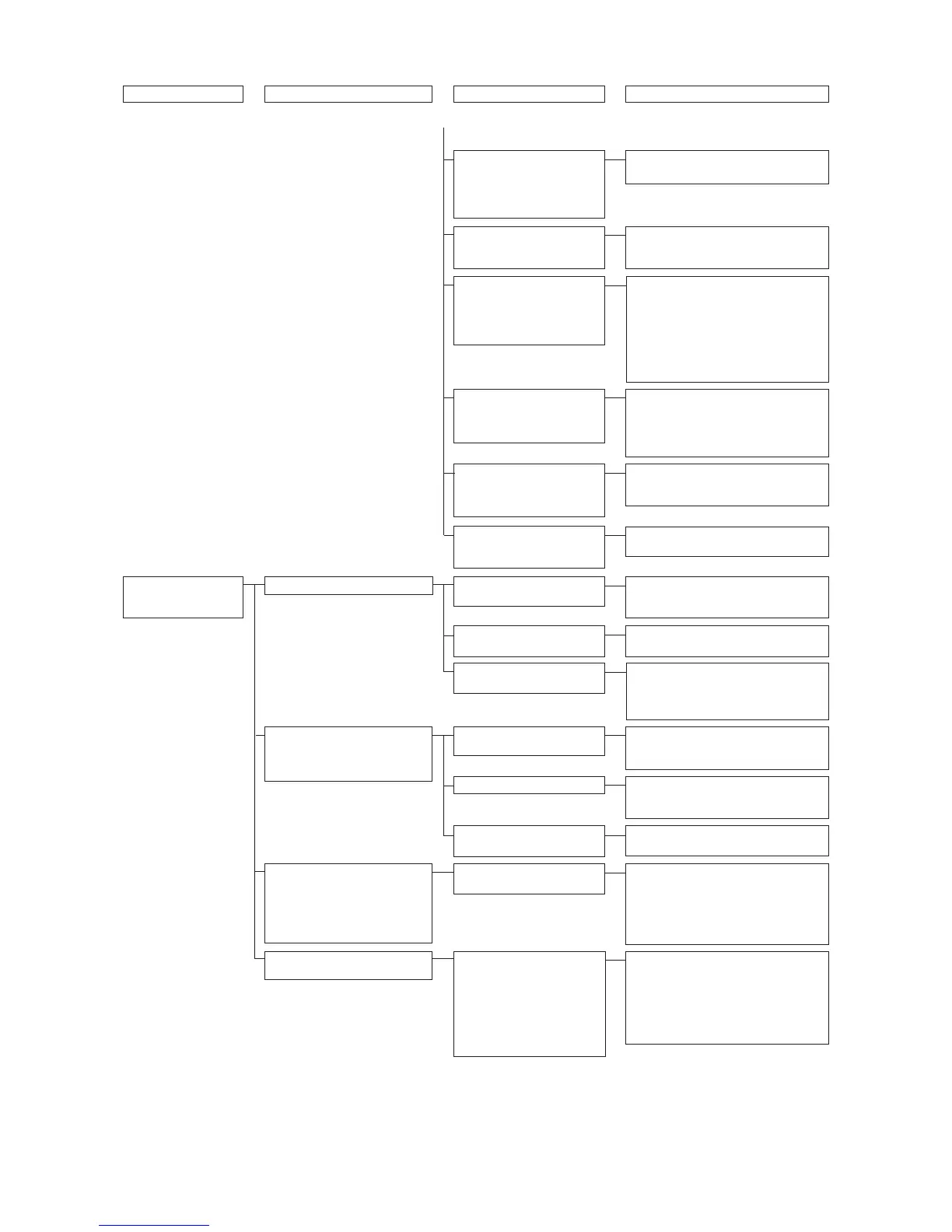

Cause (1)

Troubles

Cause (2)

Corrective measures

From the previous page

5. Needle thread is not

cut. (Bobbin thread

is cut.)

5-1) Stitch skipping at the last sti

5-2) Slackness of needle thread

during thread trimming motion is

large and needle thread cannot be

caught when moving knife returns.

5-3) When moving knife draws out

thread during thread trimming

motion, two pieces of needle

thread are simultaneously caught

at the concave section of top end

of moving knife.

5-4) A part of cutting blade section

of knife is dull.

1)-D There is a scratch on

knife thread guide, moving

knife, hook, or thread draw-

out, and trimming on the way

occurs.

1)-E Tension releasing timing

is too late and trimming on the

way occurs.

1)-F Lateral position of knife

unit is improper and thread

draw-out with moving knife

cannot be performed. (3 pcs.

trimming)

1)-G Hook timing is too early

and thread draw-out with

moving knife cannot be

performed.

1)-H Tension release timing is

too early and thread draw-out

with moving knife cannot be

performed.

1)-I Thread trimming timing is

too late and thread draw-out

cannot be performed.

1)-A Installation of needle is

wrong.

1)-B Stroke of thread take-up

spring is too large.

1)-C Hook adjustment is

wrong.

2)-A Tension release timing is

too early.

2)-B Hook timing is too late.

2)-C Thread trimming timing is

too early.

3)-A Lateral position of knife

unit is improper.

4)-A Cutting blade sections of

moving knife and counter knife

are not completely fit at the

time of thread trimming.

(Installing angle, position and

inclination of blade plane of

counter knife are not fit for the

blade section of moving knife.)

Correct the scratch with buff or replace the

part.

Check the set value of LS (Output start

angle of L output of G mode) according

to 5. Reference.

When waste thread of approximately 40

mm is fallen under throat plate, it is 3

pcs. trimming. Correct the position of

knife unit according to (5).

* When adjusting the lateral position of

knife unit, the receding amount of

moving knife varies and re-adjustment is

necessary.

(Refer to 4. - (2) Hook timing.) Correct

the hook timing (aim of return amount :

1.8 mm).

(Use the gauge supplied as

accessories.)

Refer to 5. SETTING OF SC-380. Check

the set value of LS (Output start angle of

L output of G mode).

Correct the thread trimmer cam timing

according to 4-(6).

Correctly install the needle according to

the Instruction Manual. In addition, check

the bend of needle.

Decrease the stroke of thread take-up

spring.

Check stitch skipping with sewing at low

speed and try again the hook adjusting.

(Make the hook timing somewhat

earlier.)

Check the set value of LS (Output start

angle of L output of G mode) according

to 5.

Correct the hook timing (aim of return

amount : 1.8 mm) according to the 4-(2).

(Use the gauge supplied as accessories.)

Correct the thread trimmer cam timing

according to 4-(6).

Adjust the lateral position of knife unit

according to 4-(5).

* When adjusting the lateral position of

knife unit, the receding amount of

moving knife varies and re-adjustment is

necessary.

Remove the throat plate, and move the

moving knife by hand. It is good that 3

pcs. of cotton thread #50 are evenly cut

when 3 pcs. of the thread are cut. If not,

adjust the position and sharpening

procedure of counter knife according to

4-(7) and 6-(1).

Loading...

Loading...