5)

Enhanced

series

with

easy

upgrading

• '•^ ^ ^

Thecontroller

comes

inthe

SC-20,

SC-120,

SC-220,

SC-320

and

SC-522

series,

andyoucan

easily

upgrade

them

simply

by

replacing

their

control

panels

(excluding

the

SC-522).

? ; > ..

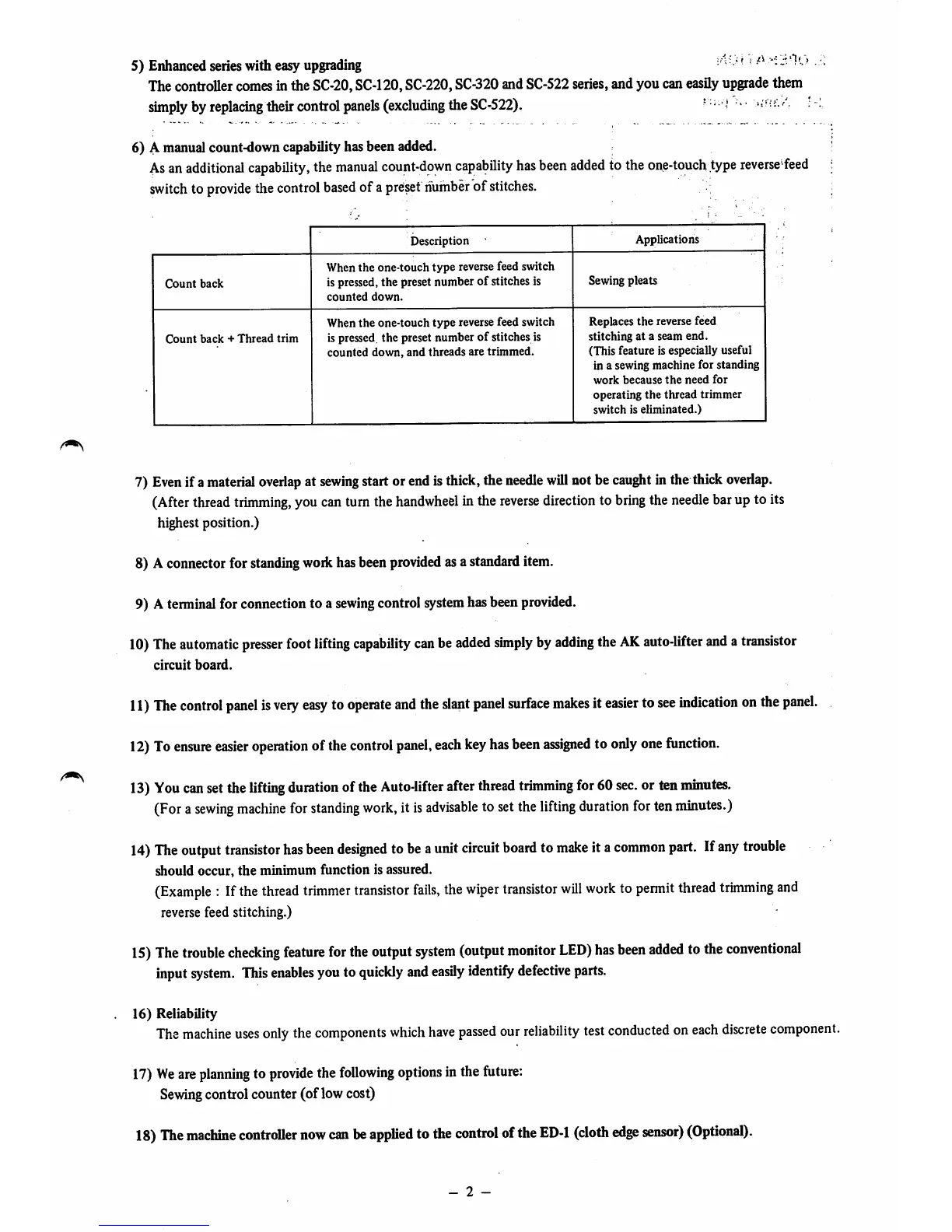

6) A manualcount-down capabilityhas been added.

As

an

additional

capability,

the

manual

count-down

capability

has

been

added

to

the

one-touch

type

reverse

feed

switch

to

provide

the

control

based

ofa

preset

number

of

stitches.

Description

Applications

Count

back

When the one-touch type reverse feed switch

is pressed,the preset number of stitches is

counted

down.

Sewing pleats

Count

back

+

Thread

trim

When the one-touch type reverse feed switch

is pressed, the preset number

of

stitches is

counted

down,

and

threads

are

trimmed.

Replaces the reverse feed

stitching at a seam end.

(This feature is especially useful

in a sewing machine for standing

work

because

the

need

for

operating

the

thread trimmer

switch

is

eliminated.)

7)

Even

ifa

material

overlap

at

sewing

startorendis

thick,

the

needle

will

notbe

caught

inthe

thick

overlap.

(After

thread

trimming,

youcanturnthe

handwheel

inthe

reverse

direction

to

bring

the

needle

barup to its

highestposition.)

8) Aconnectorfor standing workhasbeen

provided

asa standarditem.

9) A

terminal

for connection to a

sewing

control

system

hasbeen

provided.

10)

The

automatic

presser

foot

lifting

capability

can

be

added

simply

by

adding

the

AK

auto-lifter

and

a

transistor

circuit

board.

11)

The

control

panel

is

very

easy

to

operate

and

the

slant

panel

surface

makes

it

easier

to

see

indication

on

the

panel.

12)

To

ensure

easier

operation

of

the

control

panel,

each

key

has

been

assigned

to

only

one

function.

13)

You

can

setthe

lifting

duration

ofthe

Auto-lifter

after

thread

trimming

for60

sec.

or ten

minutes.

(For

a

sewing

machine

for

standing

work,

it

is

advisable

to

set

the

lifting

duration

for

ten

minutes.)

14)

The

output

transistor

has

been

designed

to

be

a

unit

circuit

board

to

make

ita

common

part.

If

any

trouble

should occur, the minimum function is assured.

(Example

: If

the

thread

trimmer

transistor

fails,

the

wiper

transistor

will

work

to

permit

thread

trimming

and

reversefeed stitching.)

15)

The

trouble

checking

feature

for

the

output

system

(output

monitor

LED)

has

been

added

to

the

conventional

input

system.

This

enables

you

to

quickly

and

easily

identify

defective

parts.

16) Reliability

The

machine

uses

only

the

components

which

have

passed

our

reliability

test

conducted

on

each

discrete

component.

17)

We

are

planning

to

provide

the

following

options

inthe

future:

Sewing

controlcounter (of lowcost)

18)

The

machine

controller

now

can

be

applied

to

the

control

of

the

ED-1

(cloth

edge

sensor)

(Optional).

- 2 -

Loading...

Loading...