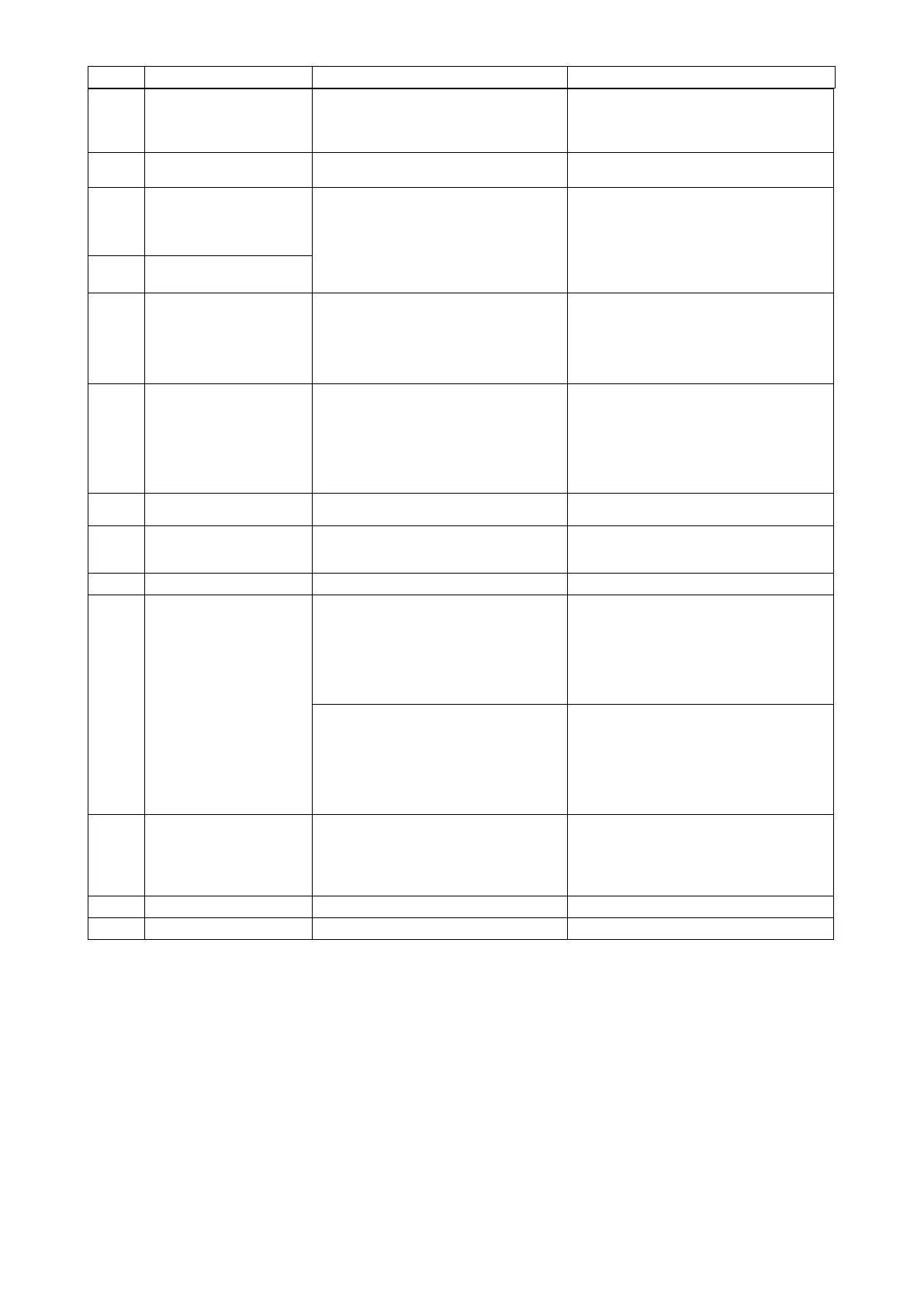

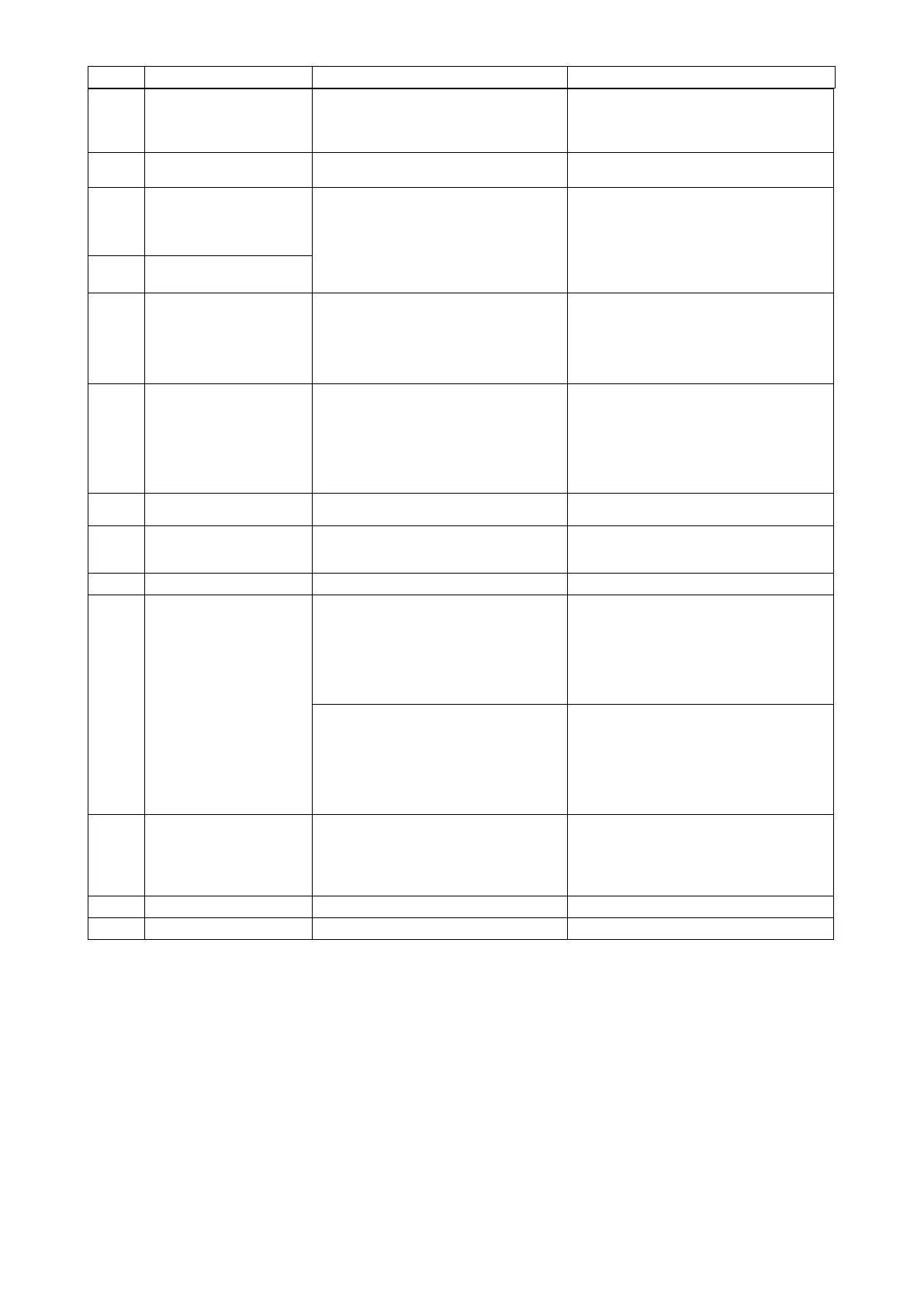

– 56 –

E703(*) Operation panel is connected

to the unexpected sewing

machine. (Error of sewing

machine model)

• The operation panel and the sewing

machine model do not match in the initial

communication.

• Connect the operation panel to the correct

model of the sewing machine.

E704(*) System version mismatch • The system version is different from the

correct one in the initial communication.

• Re-write the system version to the one that

can be used with the operation panel.

E730 Encoder failure • When the motor signal is not properly input-

ted.

• Check the motor signal connector (CN30) for

loose connection and disconnection.

• Check whether the motor signal cord has

broken since the cord is caught in the machine

head.

• Check whether the inserting direction of the

motor encoder connector is wrong.

E731 Motor hole sensor failure

E733 Inverse rotation of motor • This error occurs when the motor is run-

ning at 500 sti/min or more in the opposite

direction of that of rotation indication during

motor is running.

• Check whether the machine head corresponds

with the machine type setting.

• Check whether the main-shaft motor encoder

wire is connected incorrectly.

• Check whether the main-shaft motor wire for

power supply is connected incorrectly.

E799 Thread trimming operation

time-ou

• The thread trimming control operation is not

completed within the predetermined time

(within three seconds).

• Check whether the machine head actually

installed is different from the machine head

selection.

• Check whether the motor-pulley diameter

does not match its setting (effective diam-

eter).

• Check whether the belt has slackened.

E808 Solenoid short circuit • Solenoid power does not become normal

voltage.

• Check whether the machine head cord is

caught in the pulley cover or the like.

E809 Holding motion failure • Solenoid is not changed over to holding

motion.

• Check whether the solenoid is abnormally

heated. (CTL circuit board asm. Circuit is

broken.

E810 Solenoid current abnormality • Solenoid rare short-circuit. • Solenoid resistance

E811 Abnormal voltage • When voltage higher than guaranteed one

is inputted.

• 200V has been inputted to SC-922 of 100V

specications.

• JA : 220V is applied to 120V box.

• CE : 400V is applied to 230V box.

• Check whether the applied power voltage is

higher than the rated voltage + (plus) 10% or

more.

• Check whether 100V/200V changeover con-

nector is improperly set.

In the aforementioned cases, POWER p.c.b

is broken.

• When voltage lower than guaranteed one is

inputted.

• 100V has been inputted to SC-922 of 200V

specications.

• JA : 120V is applied to 220V box

• Inner circuit is broken by the applied over-

voltage

• Check whether the voltage is lower than the

rated voltage - (minus) 10% or less.

• Check whether 100V/200V changeover con-

nector is improperly set.

• Check whether fuse or regenerative resis-

tance is broken.

E906 Operation panel transmission

failure

• Disconnection of operation panel cord

• Operation panel has broken.

• Check the operation panel connector (CN38)

for loose connection and disconnection.

• Check whether the operation panel cord has

broken since the cord is caught in the machine

head.

E924

Motor driver failure • Motor driver has broken.

E942

Faulty EEPROM • Data cannot be written on the EEPROM. • Turn the power OFF.

* The error number attached with an asterisk (*) is displayed only in the case a fault occurs when the IT

panel is connected to the sewing machine.

No.

Description of error detected

Cause of occurrence expected Items to be checked

Loading...

Loading...