G 11

0708.USA

5.1 Operating resources

Handling of operating resources:

Operating resources must always be used properly and in accordance with the

manufacturer's instructions.

QwW Improper handling can endanger health, life, and the environment. Operating

resources must only be stored in suitable containers. They may be flammable

and must, therefore, not be brought into contact with hot components or

naked flames.

Only clean containers should be used to fill operating resources. Different grades of

operating resources should never be mixed. The only exception to this rule is if mixing

is expressly stipulated in this Operating Manual.

Be careful not to spill liquids. Liquid spillages must be removed immediately using a

suitable binder. The mixture of binder and operating resources must be disposed of

in compliance with applicable regulations.

Grease reference values

5.2 ETR tank filling quantity

Filling quantity 6.87 - 7.9 gal (26 - 30 l)

Filling quantity is independent of lift height.

Filling quantity always up to the level indicator in the tank.

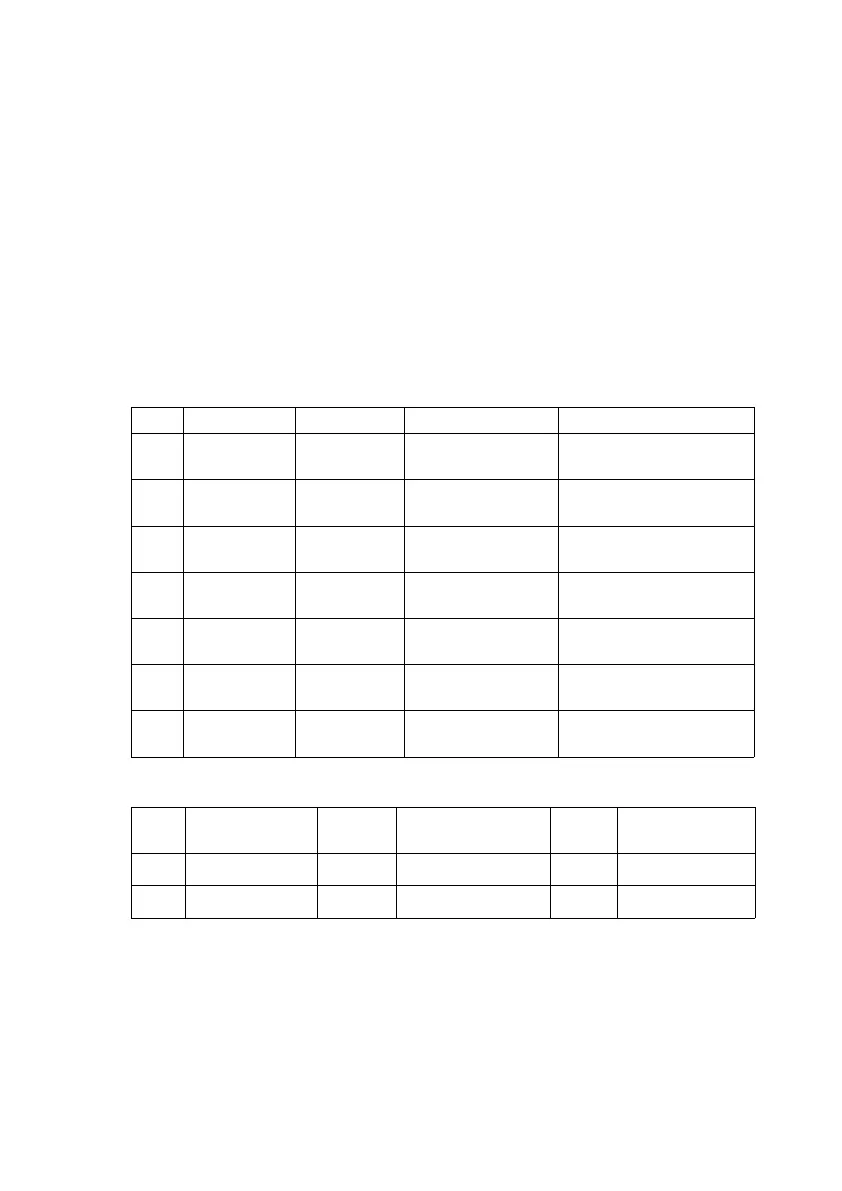

Code Order No. Quantity Designation Use for

A 50 449 669 5,0 l

1.32 gal

HLP-D 46,

DIN 51524

Hydraulic system

B 29 200 680 5,0 l

1.32 gal

CLP 100,

DIN 51517

Gearbox

C 29 200 810 5,0 l

1.32 gal

HLP 10,

DIN 51524

Gearbox

E 29 201 430 1,0 kg

2.2 lbs

Grease, DIN 51825 Lubrication service

F 50 430 702 1,0 kg

2.2 lbs

Grease, TTF52 Lubrication service

G 29 201 280 0,400 l

0.11 gal

Chain spray Chains

J 29 202 020 5 l

1.32 gal

AeroShell Fluid 41 Hydraulic system

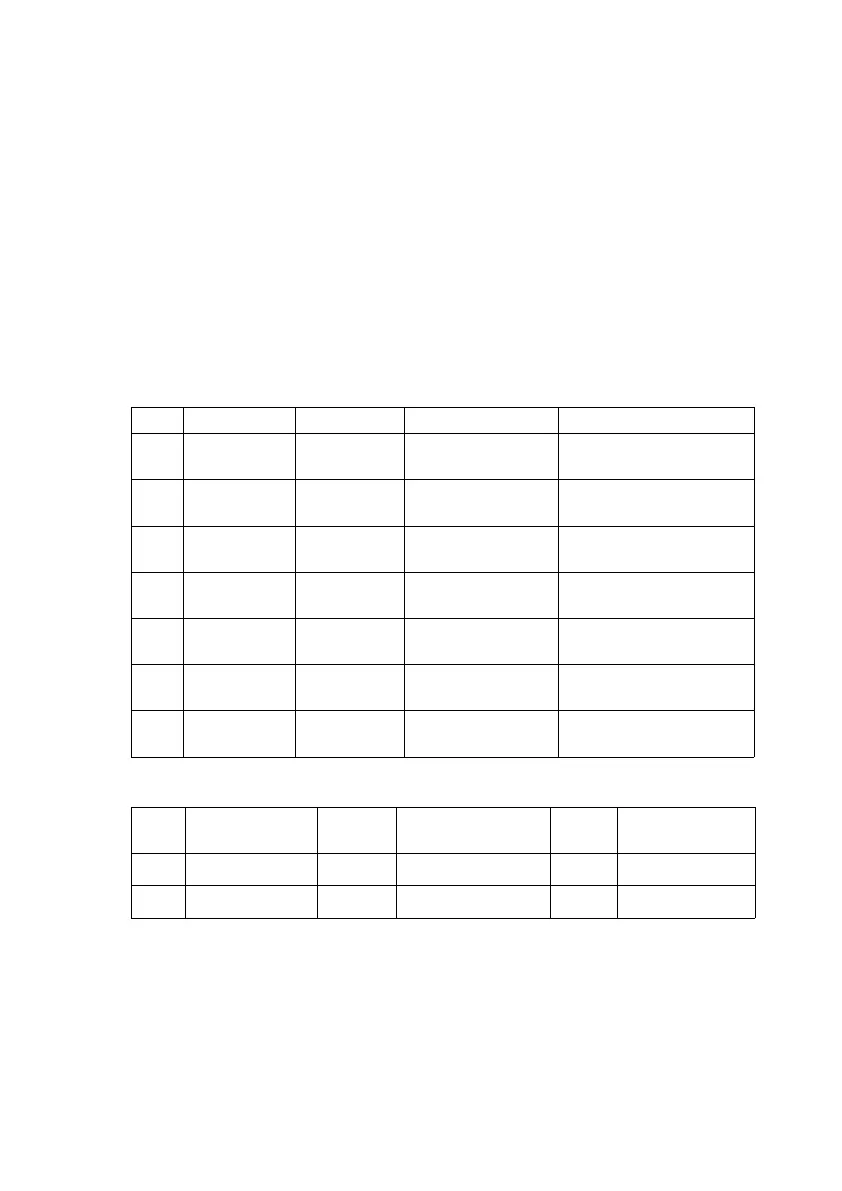

Code Saponification

type

Drop

point °C

Walk penetration

at 25 °C

NLG1

Class

Handling

temperature °C

E Lithium 185 265 - 295 2 -35 / +120

F -- -- 310 - 340 1 -52 / +100

G 11

0708.USA

5.1 Operating resources

Handling of operating resources:

Operating resources must always be used properly and in accordance with the

manufacturer's instructions.

QwW Improper handling can endanger health, life, and the environment. Operating

resources must only be stored in suitable containers. They may be flammable

and must, therefore, not be brought into contact with hot components or

naked flames.

Only clean containers should be used to fill operating resources. Different grades of

operating resources should never be mixed. The only exception to this rule is if mixing

is expressly stipulated in this Operating Manual.

Be careful not to spill liquids. Liquid spillages must be removed immediately using a

suitable binder. The mixture of binder and operating resources must be disposed of

in compliance with applicable regulations.

Grease reference values

5.2 ETR tank filling quantity

Filling quantity 6.87 - 7.9 gal (26 - 30 l)

Filling quantity is independent of lift height.

Filling quantity always up to the level indicator in the tank.

Code Order No. Quantity Designation Use for

A 50 449 669 5,0 l

1.32 gal

HLP-D 46,

DIN 51524

Hydraulic system

B 29 200 680 5,0 l

1.32 gal

CLP 100,

DIN 51517

Gearbox

C 29 200 810 5,0 l

1.32 gal

HLP 10,

DIN 51524

Gearbox

E 29 201 430 1,0 kg

2.2 lbs

Grease, DIN 51825 Lubrication service

F 50 430 702 1,0 kg

2.2 lbs

Grease, TTF52 Lubrication service

G 29 201 280 0,400 l

0.11 gal

Chain spray Chains

J 29 202 020 5 l

1.32 gal

AeroShell Fluid 41 Hydraulic system

Code Saponification

type

Drop

point °C

Walk penetration

at 25 °C

NLG1

Class

Handling

temperature °C

E Lithium 185 265 - 295 2 -35 / +120

F -- -- 310 - 340 1 -52 / +100

Loading...

Loading...