PORT

α

α

1

α

α

1

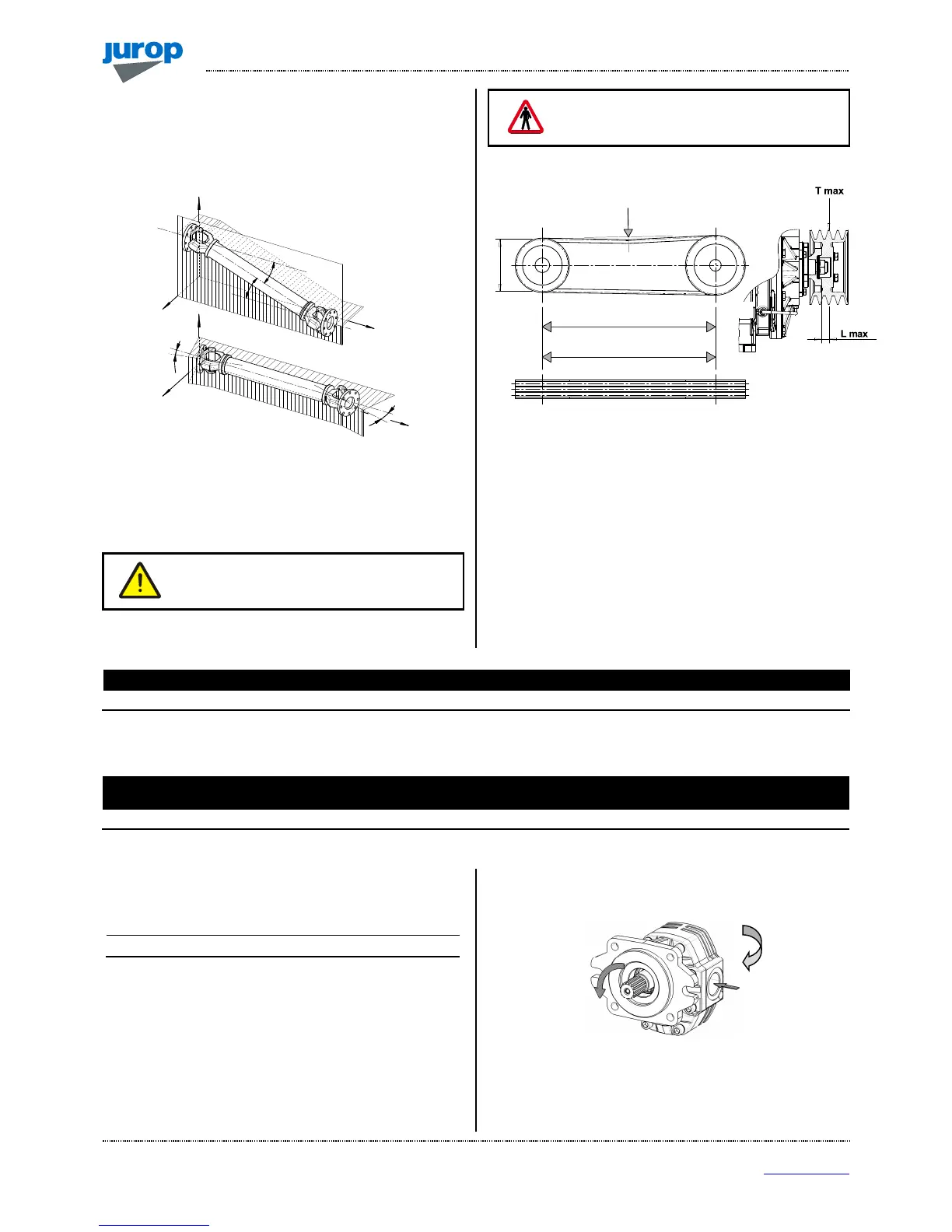

• In order to achieve a uniform motion of the driven shaft, the

following requirements must be met (see Pic. 4.5):

- Equal working angle α and α1 of both couplings;

- The internal fork joints must be coplanar;

- Both driven and driving shafts must be coplanar.

Pic. 4.5

• It is also recommended working with limited articulated joint angles

(max 15° at 1000 rpm and max 11° at 1100 rpm) and disengaging the

transmission for those operations requiring great angles (steering or

lifting).

Follow the rotation direction as indicated on the

pump front conveyor protection. Follow the

instructions of the cardan shaft’s manufacture.

• Use the protection that comes with the Julia group shaft.

Use the cardan protection supplied with the

pump. The pump installation must fulfill the

current EC injury prevention specifications.

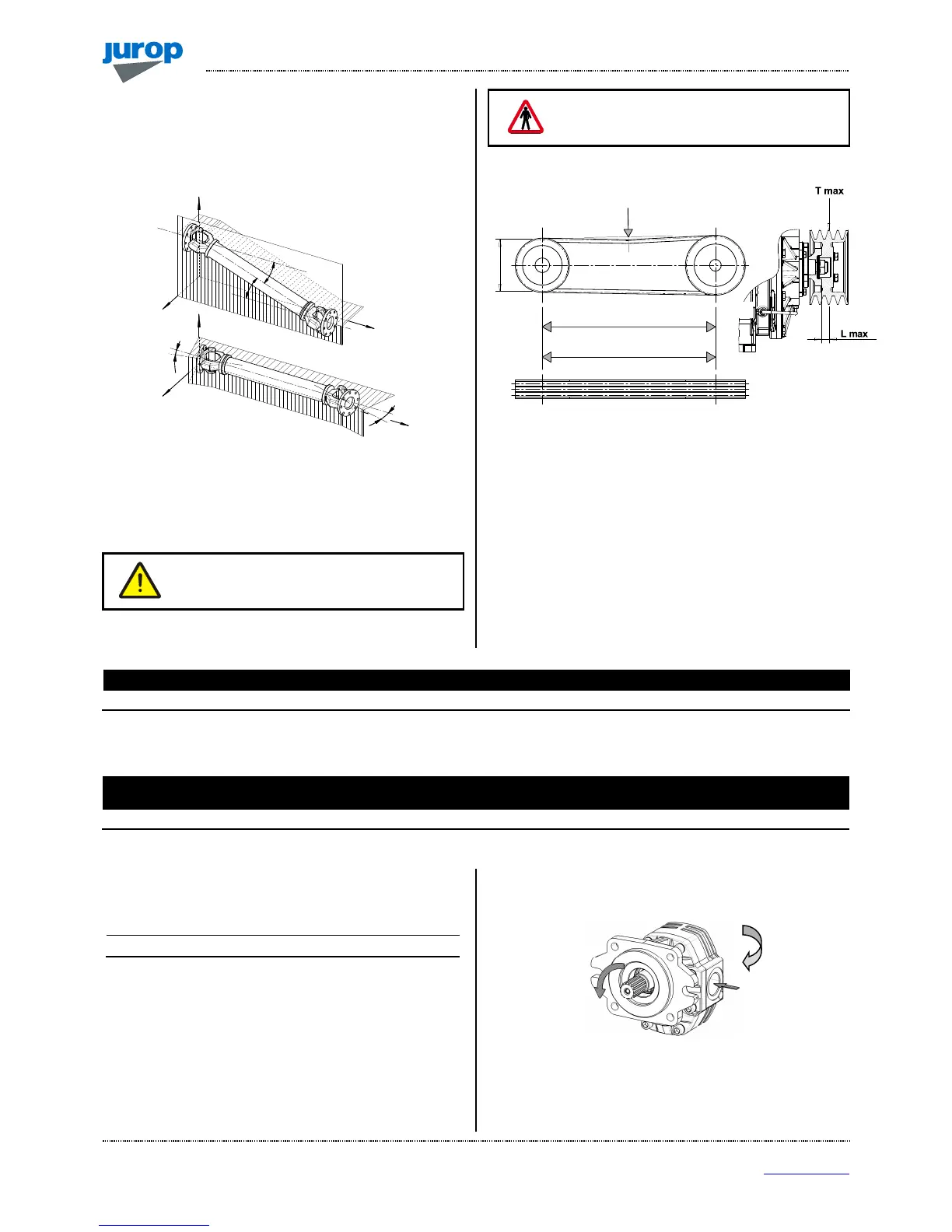

B) Belt drive

Pic. 4.6

• When using the belts and pulley, the pulley can be mounted

directly on the rotor shaft.

• Always use pulleys that are suitable to be installed on the shaft

end. Pulleys supplied by Jurop are strongly recommended. Look at the

parts breakdown at the end of this manual.

• Install the pulley, max. overhanging. L Max 20 mm.

• Max belt tension: 2500 N Max.

Model Max. Speed (rpm) T. max (N) L. max (mm) Pitch diameter (mm) Nr. Grooves Belts type

R 260 1300 2500 20 150 4 XPB

Pitch Diameter. min.: Minimum drive of pulley pitch diameter.

C) Hydraulic drive transmission

Model Displacement

Operating pressure

(max. vac.)

Flow

Max pressure

draining line

Max. pressure

motor exhaust

Max pressure

R 260 72 cc/rev 120 bar 100 l/min (1300rpm) 5 bar 5 bar 220 bar

(*) : Oil temperature, used in the main circuit.

• Fluid: mineral oil for hydraulic systems in compliance with

ISO/DIN.

Temperature Optimum viscosity ale Max. viscosity allowed

-20 / +80 °C 12 – 100 cSt 750 cSt

• Filtration: class 21/19/16 contamination according to ISO 4406 to

be obtained with a ßx = 75 filter.

• Check circuit connections: they must be applied in the same

rotation direction as that indicated by the arrow on the pump front

flange.

• Draining: connect directly to the tank above the maximum oil

level. Operating without draining line may damage the motor.

Pic. 4.7

• Distributor: open-centre distributor in central idle position

(vacuum pump off). It must be equipped with an adjustable

overpressure safety valve.

KEEP AXELS PARALLEL

Loading...

Loading...