6.1. Ordinary maintenance

• Installation and maintenance must be operated only by qualified personnel wearing the proper clothes and the necessary tools as well as

protection devices.

• Use suitable protection equipment (gloves, protection glasses, boots...)

• In the following table summarizes the main controls to be performed and the frequency of intervention.

Operating condition Maintenance Area Check 8

H

50

H

500

H

1000H

OPERATING

Vacuum line

Check safety valve (non-return valve)

Operating pressure

Transmission / Pump

Rotation speed

Sound pressure level (also HDR motor)

STANDSTILL

Vacuum line

Suctions filters

4-way changeover valve: check and lubricate

Pump

Sintered filter cleaning

Check vanes wear

Change oil in the gear box, if the pomp is provided with it (*)

Pump’s inner washing (**)

Overall

Greasing

Check cardan shaft drive

Chack transmission pulley

(*) The first oil change must be done inside 500 hours operation. Following

changes every 5000 hours or 12 months. In order to choose the most suitable oil, see

paragraph 2.5.

(**) After operation in dusty environments, after accidental sucking of liquids

inside the pump or before a long inoperativity period it is recommended to wash the

pump inside according to the procedure described at paragraph 5.2.

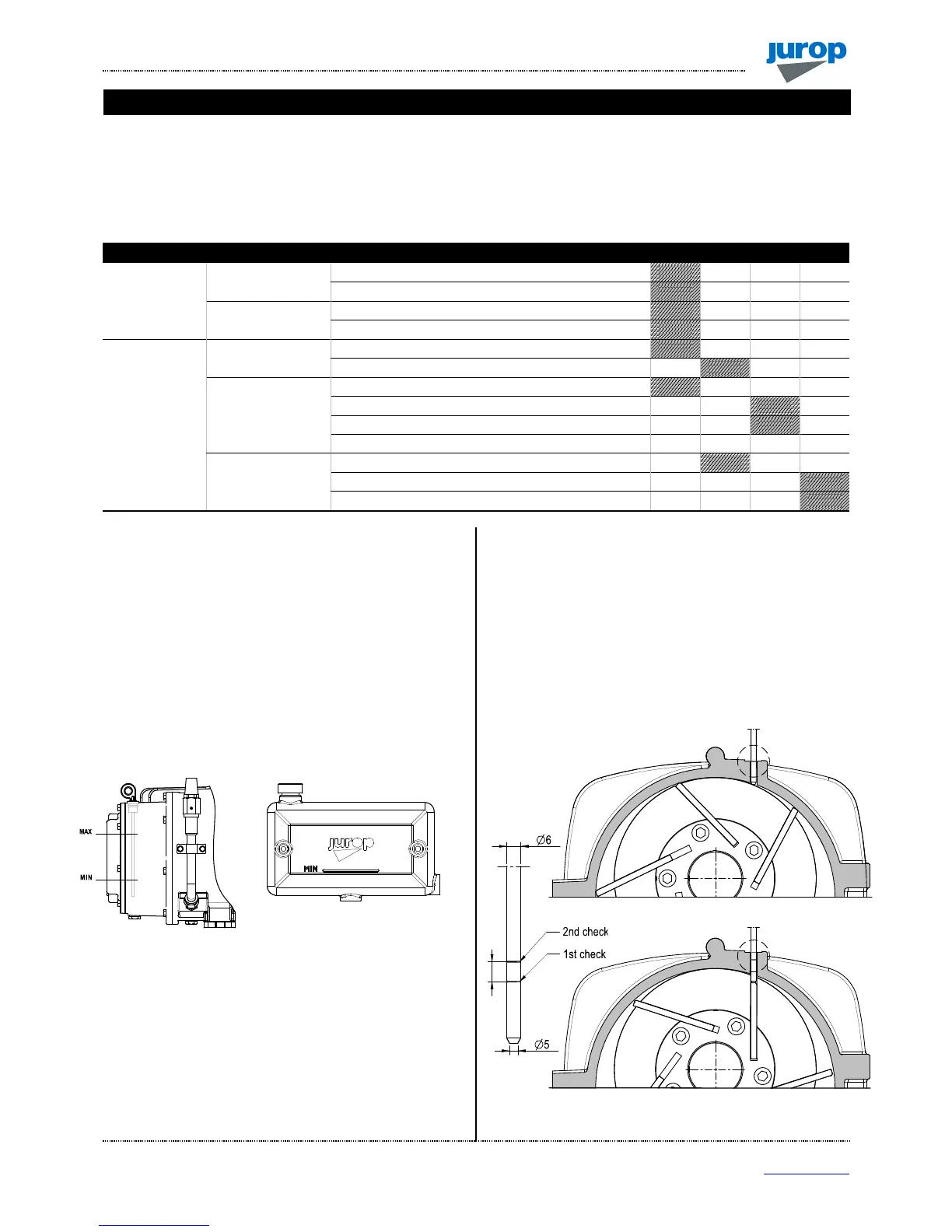

Checking the oil tank level

• Check the oil tank level.

• Do not run the pump with oil level under the minimum level: that

may lead to dry functioning and cause serious damages. (Fig. 6.1).

Pic. 6.1

• Rear mounted tank capacity: 2,3 l.

• Side mounted tank capacity: 4 l.

• Use pure and fresh oil. In order to choose the most suitable oil,

see paragraph 2.5.

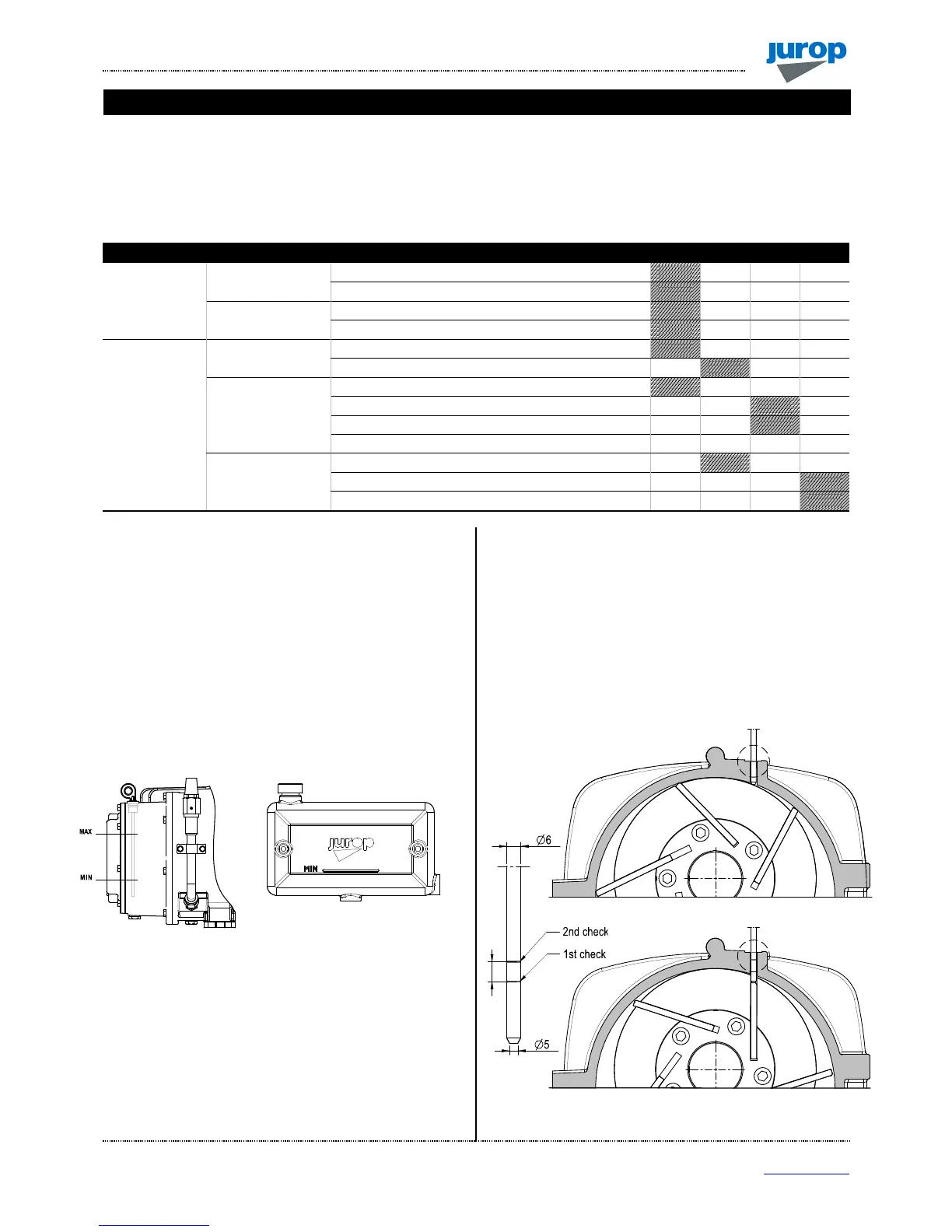

Checking the vanes wear

• Unscrew the vanes wear check-plug on the rear flange. See Pic.

4.1.

• Turn the shaft by hand until vanes appearance.

• Vanes usually slip on seat bottom due to gravity. Check their right

entry in the seat.

• Insert a Ø 6 mm stick until it touches the rotor and then mark like

in Pic. 6.2.

• Turn the rotor slowly until the stick touches the vane in idle

position in its seat. The vanes slide to the bottom of the seat due to

gravity: check they really do and mark again on the stick.

• Repeat the same procedure for all the vanes. If wear exceeds 5

mm: replace the vanes as soon as possible.

Pic. 6.2

Loading...

Loading...