http://www.jurop.it

e-mail: info@jurop.it

• Remove the port guards when mounting. The pipes and

components of the whole line must be clean.

• Avoid constrictions and tight curves where they are not essential.

• Connect the pump to the tank through the suction manifold (Fig.

4.1 - pos. 8) which has a threaded port for fitting the over-pressure

valve.

• The exhaust pipes can reach high temperatures. Protect those

adequately from the operator reach.

• A clapet valve on suction pipe avoids rotation in the opposite

direction when the pump stops.

• To avoid that foreign liquids will enter the vacuum pump it is

necessary to mount on the suction line an over-flow valve of “floating-

ball” type (Fig. 4.2. - pos. 1). The flow section of this valve must be

equivalent to the suction hose’s one.

• It is also necessary to have on the line a suitable air filter for

preventing solids to be sucked inside the vacuum pump. It is also

recommended to mount a “secondary shutoff” of floating-ball type (Fig.

4.2 - pos. 2) between vacuum pump and over-flow (primary shutoff),

along with the previously mentioned air filter (Fig. 4.2 - pos. 3).

• Called also 4-way valve, normally is manually operated but it can

be at any time transformed in pneumatically or hydraulic operated upon

request of the appropriate kit.

• During normal running of the pump the resulting noise should be

reduced by means of a suitable silencer (Fig. 4.2 - pos. 4) mounted as

close as possible to the pump itself. It has to be dimensioned for the air

flow produced by the pump model. The oil used for the pump’s inside

lubrication has to be separated from the exhausted air by means of an

adequate oil-separator, placed directly inside the silencer. The silencer

is fitted also with a draining tap for the collected oil and condensed

liquids

• Over-pressure safety relief valve. It must be dimensioned to

discharge the entire air-flow of the pump. The adjustement of this valve

has to be kept inside 10% of tollerance of the pump's working pressure

and in any case it has to stay inside the given value of the tank's work

pressure.

• For pumps that reach, during normal operating, discharge air

temperature close to 150 °C (300°F) - (checked at not more than 150

mm from the discharge connection) it is necessary to use a device

(overheating limiter) that will not allow to exceed such temperature.

Contact our Technical Department.

• An adjustable curved pipe is installed on the outlet of the silencer,

in order to prevent rain from entering and to enable positioning (during

installation) of the output airflow.

• Direct the silencer discharge output away from the silencer suction

inlet in order to prevent the input of hot fluids into the injection inlet.

Attention: direct the silencer discharge output

away from the silencer suction inlet.

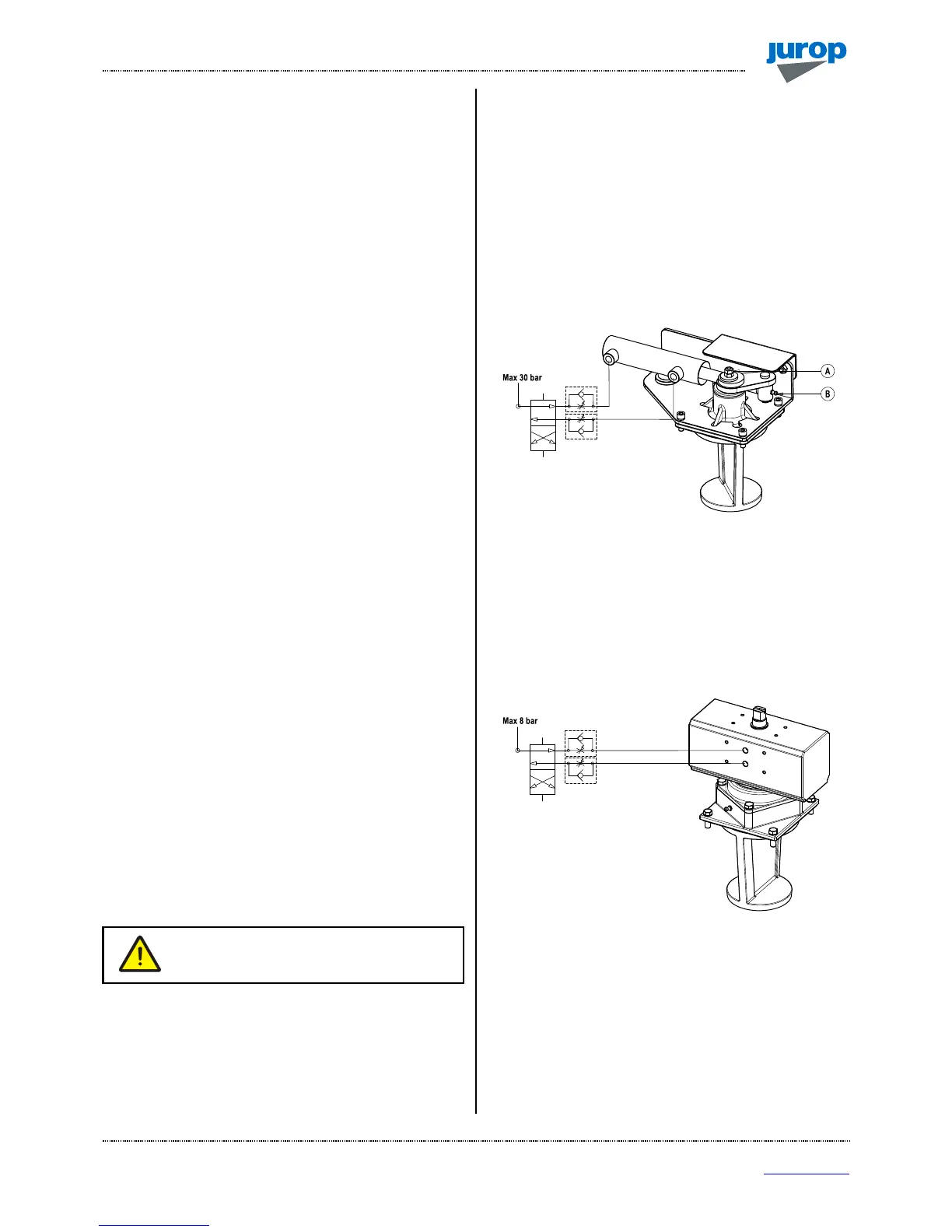

4.5 Hydraulic actuator adjustment

• Extraordinary maintenance operations can require the upper cover

(and that of the actuator, either manual or pneumatic) to be removed.

We recommend ensuring enough space to carry out such operations.

• If the cock blocks or it moves with friction, screw up the clearance

regulation nut (A). Screw up ¼ of turn each time. Block the nut rotation

with the safety nut.

• The lubrication points (B) and the clearance regulation bolt (A)

must be accessible. See Fig. 4.5.

• Lubricate with grease every 1000 cycles. Grease type NLGI 2.

• It is suggested to install 2 one‐way flow controller between the

hydraulic switch and the hydraulic actuator. Set the flow controllers in

order to prevent hard hitting through the end of stroke. Minimum

commutation time: 1 second.

• Maximum feed pressure: 30 bar.

• To order spare parts see spare parts list at the end of this manual.

Pic. 4.3

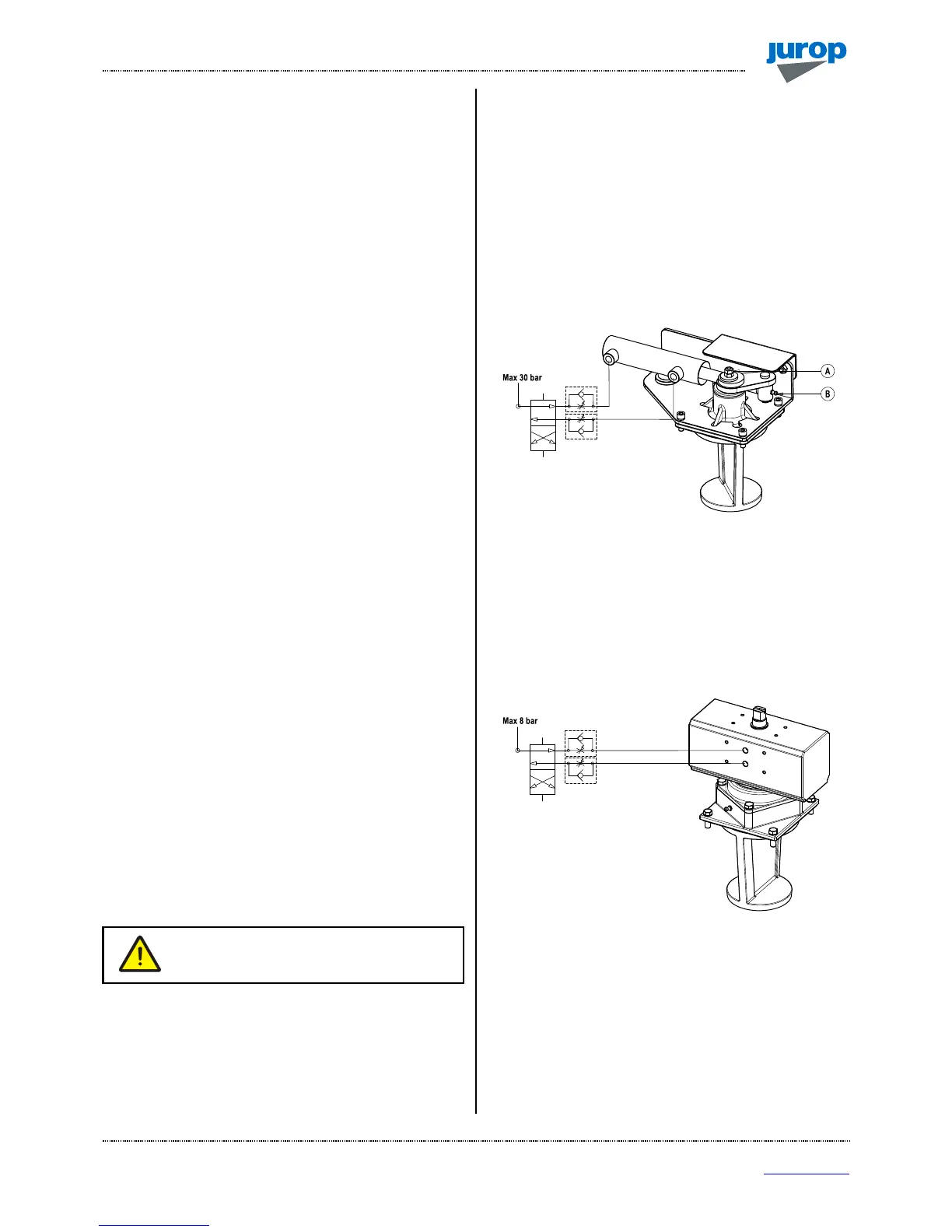

4.6 Pneumatic actuator adjustment

• In the event of 4-way valves equipped with pneumatic actuator, we

recommend installing two one-way flow regulators between the

pneumatic “control” and the pneumatic actuator. The following figure

shows a schematic view of a possible pneumatic installation.

Pic. 4.4

• We recommend adjusting the two flow regulators in order for

rotation to occur without knocks and with a switching time of at least

one second.

4.7. Pump mounting - drive connection

A) Cardan shaft drive

• Use telescopic cardan shafts.

Loading...

Loading...