http://www.jurop.it

e-mail: info@jurop.it

Attention:

Carefully apply these prescriptions.

3.1 General recommendations

• Installation and maintenance must be carried out with the unit

totally disengaged from its drive system and must be performed by

qualified personnel.

• Use adequate clothing (avoid ties, loose sleeves, necklaces and

so on) and suitable protection equipments (gloves, protection glasses,

boots...).

• To prevent errors and hazardous situations, establish what each

operator is responsible for in the different maintenance operations.

• When transporting the pump, use proper slinging. Store the pump

in stable places.

• Make sure that all the parts of the unit are idle and cool, before

performing any maintenance operation.

• Before each maintenance operation, stop the pump and restore

the atmospheric pressure.

• When the pump is running, some parts may reach very high

temperatures (above 100°C). Use all necessary precautions to avoid

contact.

• Operators working nearby must avoid prolonged exposure to the

noise emitted by the aspirator, if not equipped with the proper ear-

protection devices.

• Avoid accidental suction of solids: solids may be projected at high

speed through the exhaust manifold and cause injures. A filter must be

mounted on the sunction line.

• Do not start the machine if the protection devices provided for

transmissions are removed. Replace damaged parts.

• Pressure relief valve: point the air flux away from the operators.

• Do not use the aspirator over its designed limits: the machine may

be damage and the operator may be injured.

Do not exceed the power supply parameters

indicated in the technical tables (see par. 2.4).

3.2 Intended use

• The vacuum pumps RV are designed to convey filtered air into

systems for the vacuum production (example: systems for the suction

of powders or liquid wastes). Any other usage shall be considered

improper.

• Do not sack toxic substances and inflammable or explosive

gasses, since the internal components of the pump may reach high

temperatures.

• Liquids or solids infiltrations can seriously damage the pump.

• Do not run the pump over its designed operating limits (see par.

2.4): it may break and transmission can be damaged.

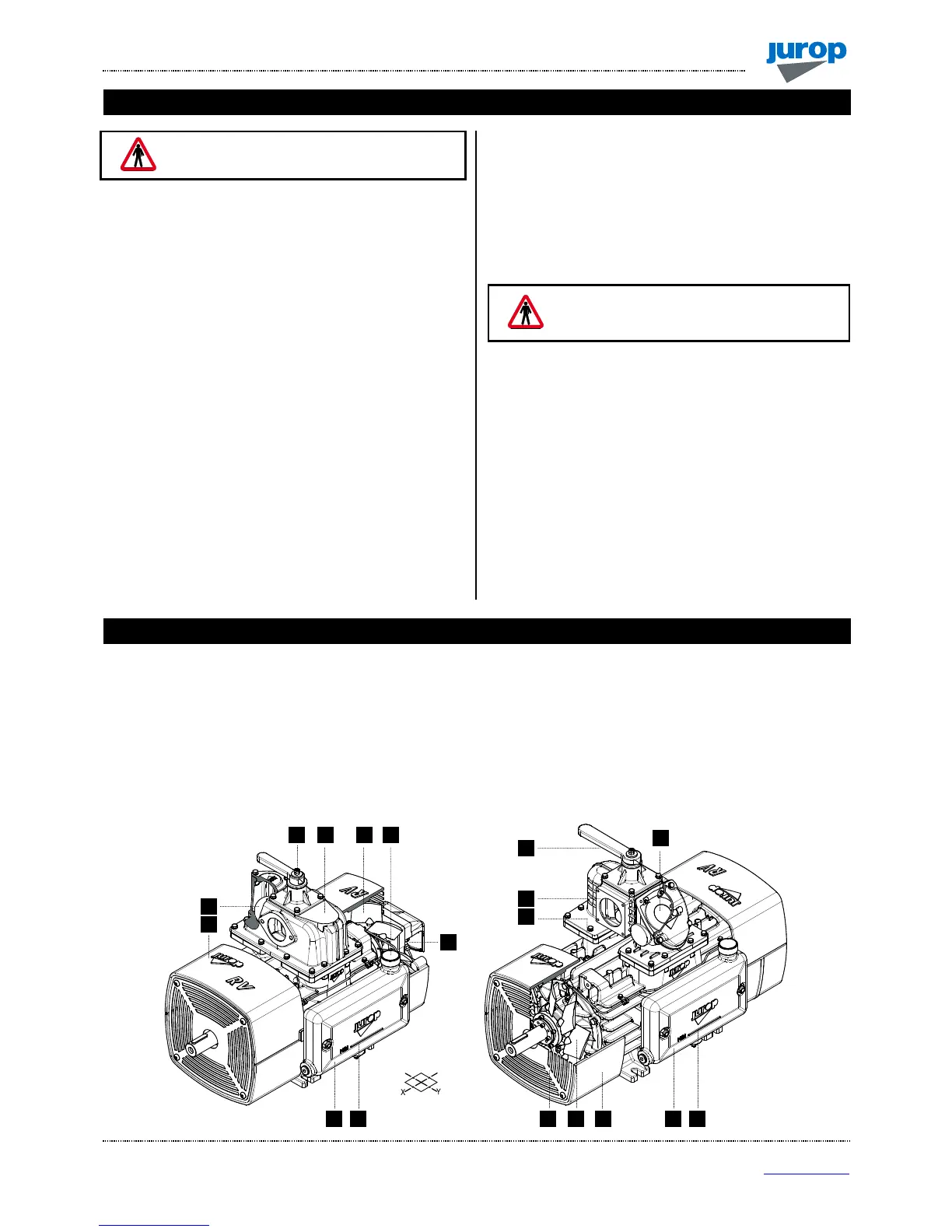

Legend of main components

1. Manifold 5. Oil Tank 9. Lubrication pump

2. Vacuum-pressure manifold 6. Tank oil stand 10.

Loading...

Loading...