http://www.jurop.it

e-mail: info@jurop.it

Checking lubrification

• Check the correct operation of the system / lubrication circuit.

If the pump is running without lubrication, the

internal components may quickly damaged due to

overheating. Stop the vacuum pump and check the

oil level and the lubricating pump.

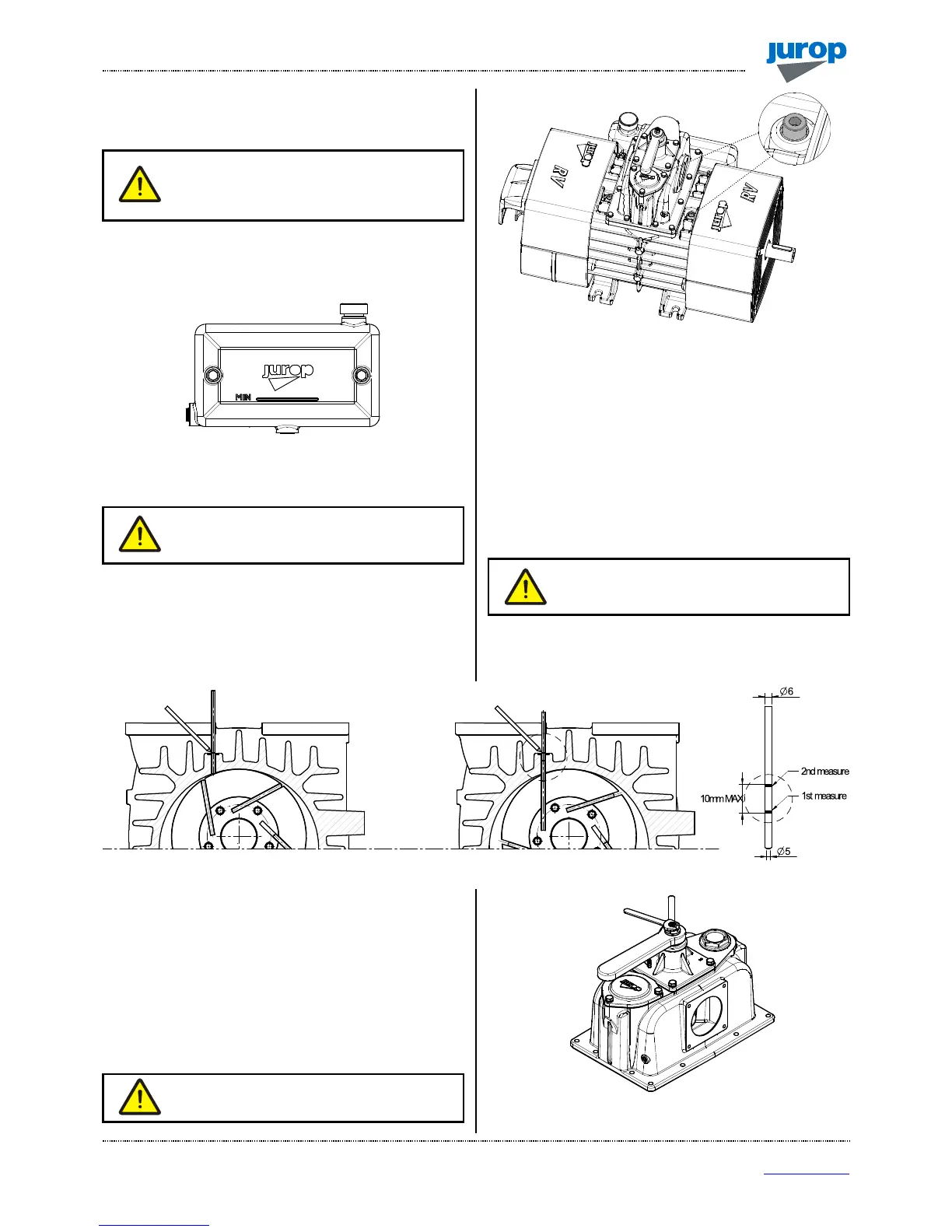

Checking the rear mounted oil tank level

• Do not run the pump with oil level under the minimum level: that may

lead to dry functioning and cause serious damages. See Fig. 6.1.

Pic. 6.1

• Tank capacity: 4l.

• Use pure fresh oil.

Do not re-use the exhausted oil gathered on the

bottom of the exhaust silencer.

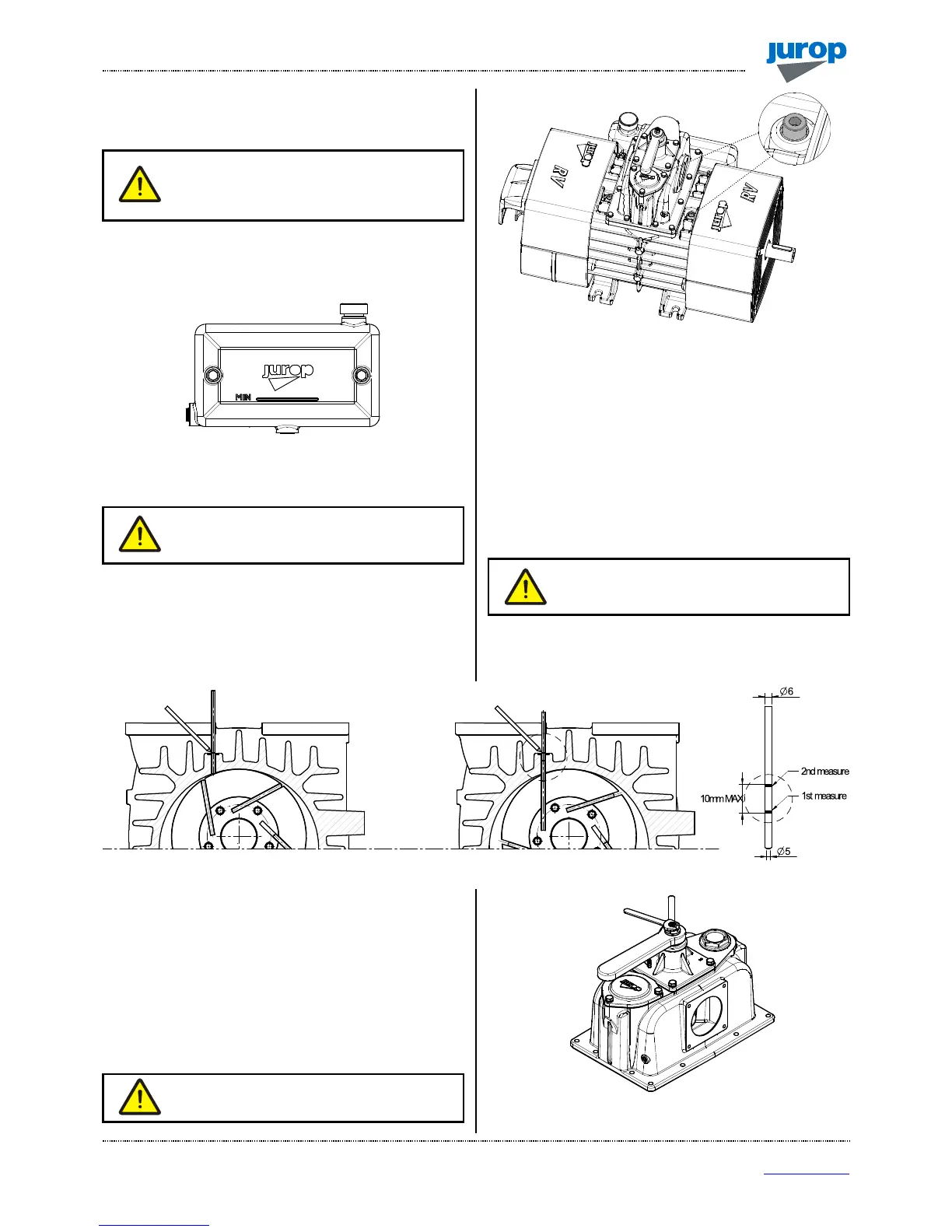

Checking the vanes wear

• Unscrew the vanes wear check-plug on the front flange. See Fig.

6.2.

• Turn the shaft by hand until vanes appearance.

• Vanes usually slip on seat bottom due to gravity. Check their right

entry in the seat.

Pic. 6.2

• Insert a Ø 5 mm stick until it touches the rotor and then mark (see

Fig. 6.3).

• Turn the rotor slowly until the stick touches the vane in idle

position in its seat. The vanes slide to the bottom of the seat due to

gravity: check they really do and mark again on the stick.

• Repeat the same procedure for all the vanes. If wear exceeds 10

mm: replace the vanes as soon as possible.

• Maximum acceptable wear: 12 mm. Immediately replace: vanes

are likely to break down.

• Replace all the pump vanes at the same time.

Replace the vanes when their wear exceeds 12

mm (L – L min): they may break. Replace all

vanes at the same time.

• Replace the cap after the measurement.

Pic. 6.3

6.2. Extraordinary maintenance

• Before starting any extraordinary maintenance operation, be sure

the pump stands still and follow the safety prescriptions as described in

Cap. “Safety and accident prevention”.

Adjusting the 4-way valve

• For pumps equipped with handle for manual operation or actuator.

• Adjust the screws to avoid the valve blocking in its seat (see Fig. 6.4).

Attention: do not exceed with the adjustment:

possible vacuum loss

Pic. 6.4

Loading...

Loading...