Section 3 - 17

Key Cutting & Pinning

Comparing A2 Pin Stacks

The examples on this page show pinning for key

symbol 1AA.

W

hen pinning conventional cylinders, ignore the con-

trol bitting. If a top pin of 20 or greater is needed,

use two pins of equal length to bring the pin stack to

the required height. When an odd numbered top pin

is required, such as 21, use two pins that are close

in size—11 and 10 instead of 13 and 8.

For the patent pin chamber in all conventional cylin-

ders, insert the proper bottom and top patent pins,

then insert a number 7B top pin.

Pinning for all Peaks products can now be accom-

plished with only one spring. That stainless steel

spring is number 3800-00-4010.

Note: Peaks Preferred Patent Pins for illustration

only. (See key pinning section 3 - 4 to 3 - 12)

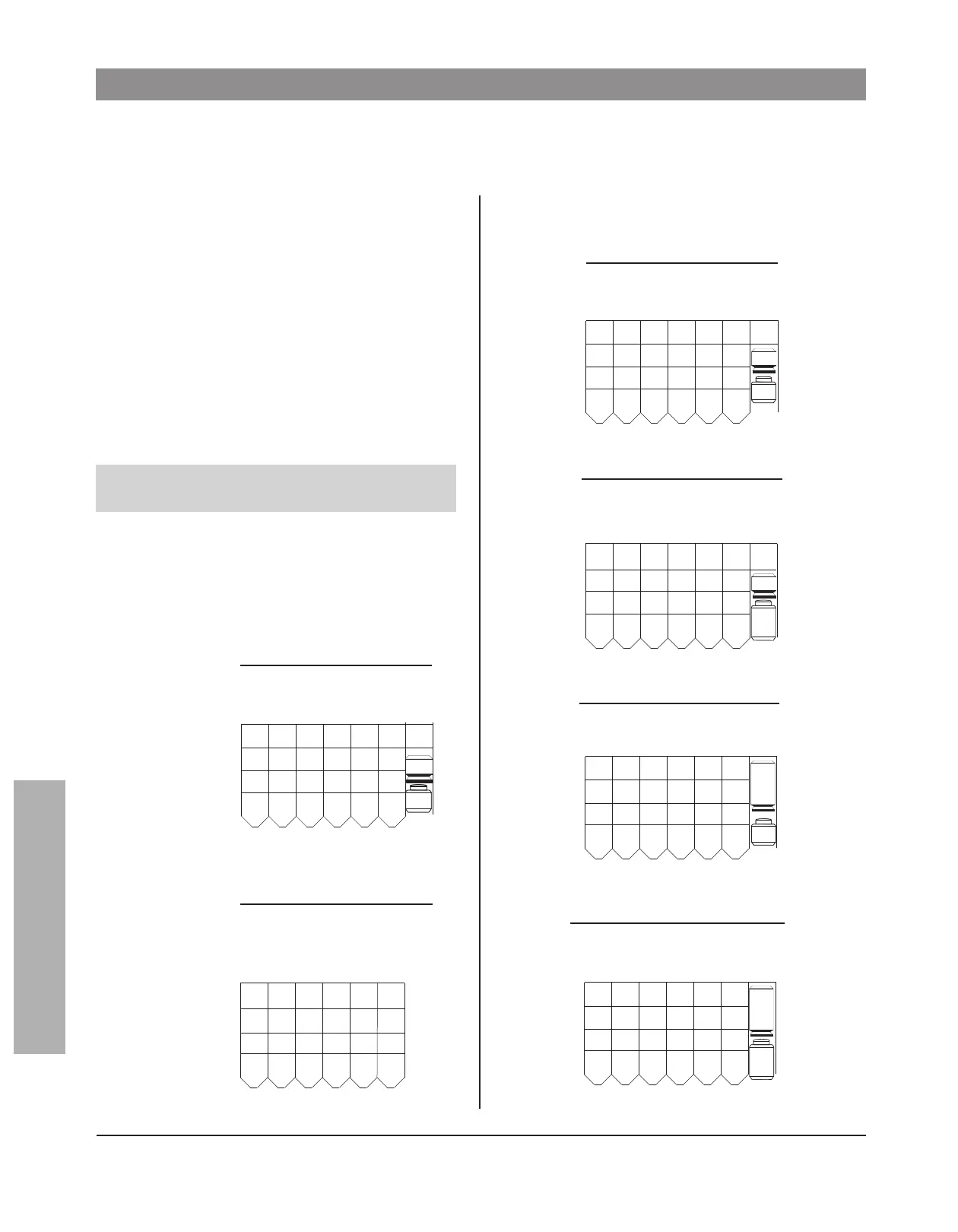

Stack height 26

control CTR 779631

master AA 951473

change 1AA 593875

top 17 17 12 18 19 11

buildup 11 10

master 4424- 2

bottom 551473

7B

8400-xx-1206

3400-xx-1206

Key-in-Knob

8401-xx-1210

3401-xx-1210

Rim/Mortise

top 11 11 14 12 12 13

buildup 11 11 14 11 12 13

master 4424- 2

bottom 551473

7B

8800/8900

3800/6800

Small Format

Interchangeable Core

top 664710 12

control 8816 866

master 4424- 2

bottom 551473

Stack height 31

Stack height 23

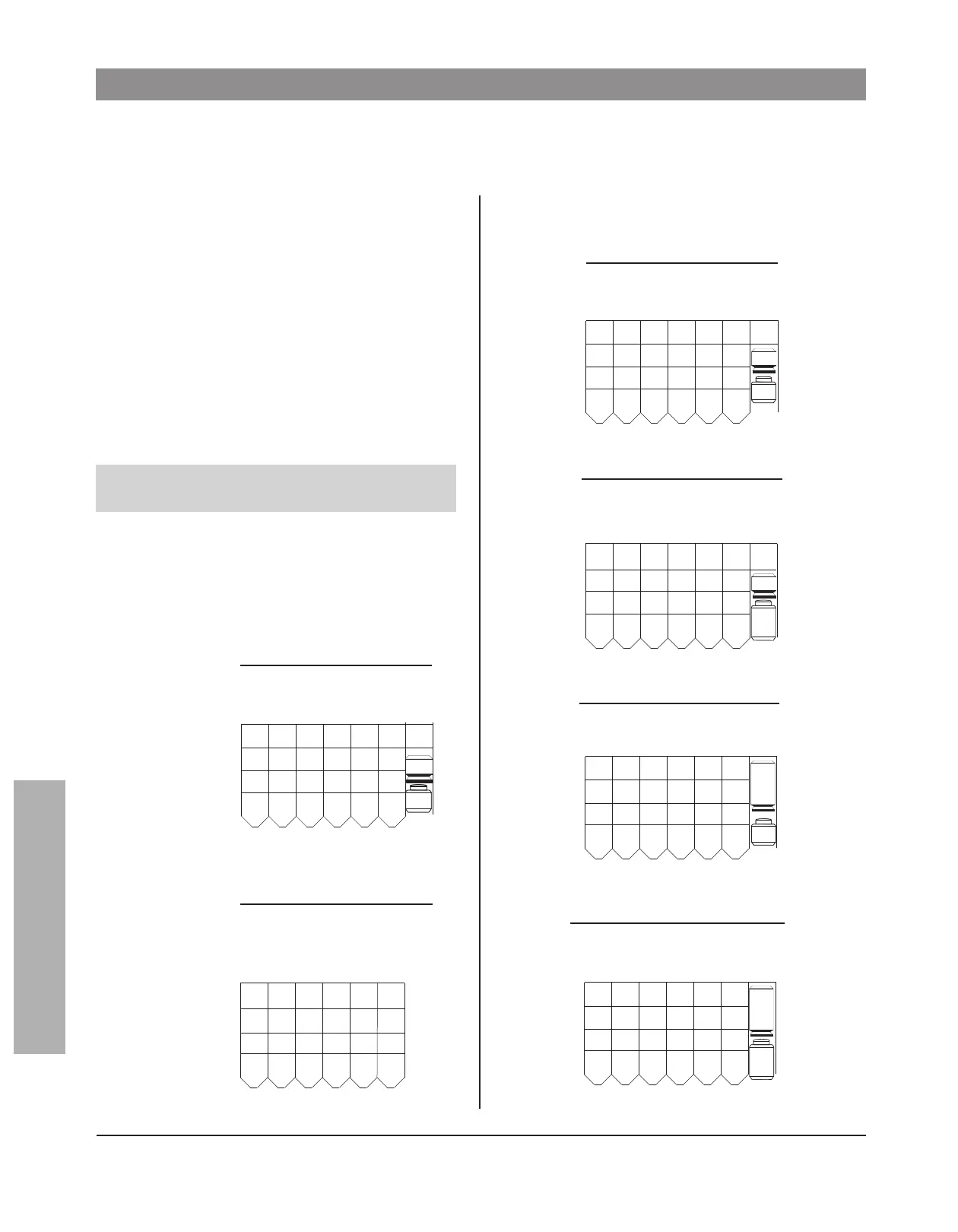

8400-xx-1299

3400-xx-1299

"99" and "95" Key-in-Knob

top 17 17 12 18 19 11

buildup --11 --10

master 4424- 2

bottom 551473

7B

8244-xx-1206 Yale

6240-xx-1206 Yale

6340-xx-1206 Medeco

top 99710 13 15

control 8816 866

master 4424- 2

bottom 551473

8144-xx-1206

6140-xx-1206

Corbin Russwin

top 99710 13 15

control 8816 866

master 4424- 2

bottom 551473

Calculating Other A2 Pinning Stacks

Loading...

Loading...